All-water-blown asphalt-polyurethane hard foam and preparation method thereof

A rigid foam, all-water foaming technology, applied in the field of polyurethane, can solve the problems of cyclopentane foaming agent being inflammable and explosive, not meeting environmental protection requirements, and high equipment requirements, achieving good waterproof and anti-corrosion performance, and solving rough skin. , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

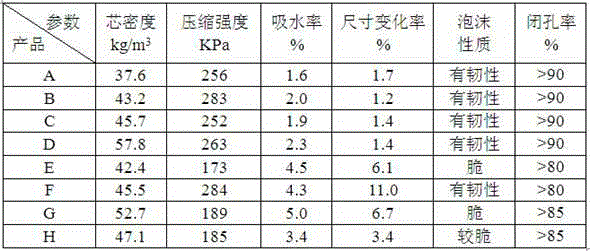

Examples

Embodiment 1

[0039] (1) Add 80 parts of petroleum asphalt with a penetration of 8mm and a softening point of 48°C into the reactor, heat to melt and stir, raise the temperature to 200°C and keep it for about 1 hour, then add 35 parts of castor oil and 3.5 parts of glycerin After mixing evenly, gradually add it to the melted petroleum asphalt, and stir vigorously at 160°C for 1 hour to obtain a mixture of asphalt and castor oil;

[0040] (2) Add 80 parts of polyether polyol and 3 parts of plasticizer dioctyl phthalate to the mixed solution prepared in step (1), and continue stirring at 60°C for 2 hours to obtain a uniform mixture;

[0041] (3) Then add 6 parts of water, 3 parts of POLYCATSA-1, 12 parts of silicone foam stabilizer, and 30 parts of trichloroethyl phosphate into the mixture prepared in step (2), and stir evenly at 38°C;

[0042] (4) Add 115 parts of PAPI to the mixture prepared in step (3), stir at a high speed for about 40 seconds, then injection mold and foam, and after curi...

Embodiment 2

[0044] (1) Add 100 parts of petroleum asphalt with a penetration of 12mm and a softening point of 56°C into the reaction kettle, heat to melt and stir, raise the temperature to 200°C and keep it for about 1 hour, then add 50 parts of castor oil and 4 parts of glycerin After mixing evenly, gradually add it to the melted petroleum asphalt, and stir vigorously at 160°C for 1 hour to obtain a mixture of asphalt and castor oil;

[0045] (2) Add 80 parts of polyether polyol and 5 parts of plasticizer dioctyl phthalate to the mixed solution prepared in step (1), and continue stirring at 70°C for 2 hours;

[0046] (3) Then add 4.5 parts of water, 1 part of DABCODC-2, 8 parts of silicone foam stabilizer, and 25 parts of trichloroethyl phosphate to the mixture prepared in step (2), and stir evenly at 45°C;

[0047] (4) Add 130 parts of PAPI to the mixture prepared in step (3), stir at a high speed for about 40 seconds, then injection mold and foam, and after curing and molding, the asph...

Embodiment 3

[0049] (1) Add 60 parts of petroleum asphalt with a penetration of 18mm and a softening point of 41°C into the reactor, heat to melt and stir, raise the temperature to 200°C and keep it for about 1 hour, then gradually add 40 parts of castor oil to the melted In the petroleum asphalt, stir vigorously at 160°C for 1 hour to obtain a mixture of asphalt and castor oil;

[0050] (2) Add 80 parts of polyether polyol and 6 parts of plasticizer dioctyl phthalate to the mixed solution prepared in step (1), and continue stirring at 80°C for 2 hours;

[0051] (3) Then add 2.5 parts of water, 1 part of DABCODC-2, 8 parts of silicone foam stabilizer, and 20 parts of trichloropropyl phosphate to the mixture prepared in step (2), and stir evenly at 42°C.

[0052] (4) Add 110 parts of PAPI to the mixture prepared in step (3), stir at a high speed for about 40 seconds, then injection mold and foam, and after curing and molding, the asphalt polyurethane rigid foam C can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com