Reductive cleaning agent for synthetic fibers as well as preparation method and application of reductive cleaning agent

A synthetic fiber and cleaning agent technology, applied in dyeing, textiles and papermaking, etc., can solve problems such as the decline of active ingredients, high transportation risks and transportation costs, and damage to workers' health, and achieve long-lasting efficacy, low transportation costs and risks, Full effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

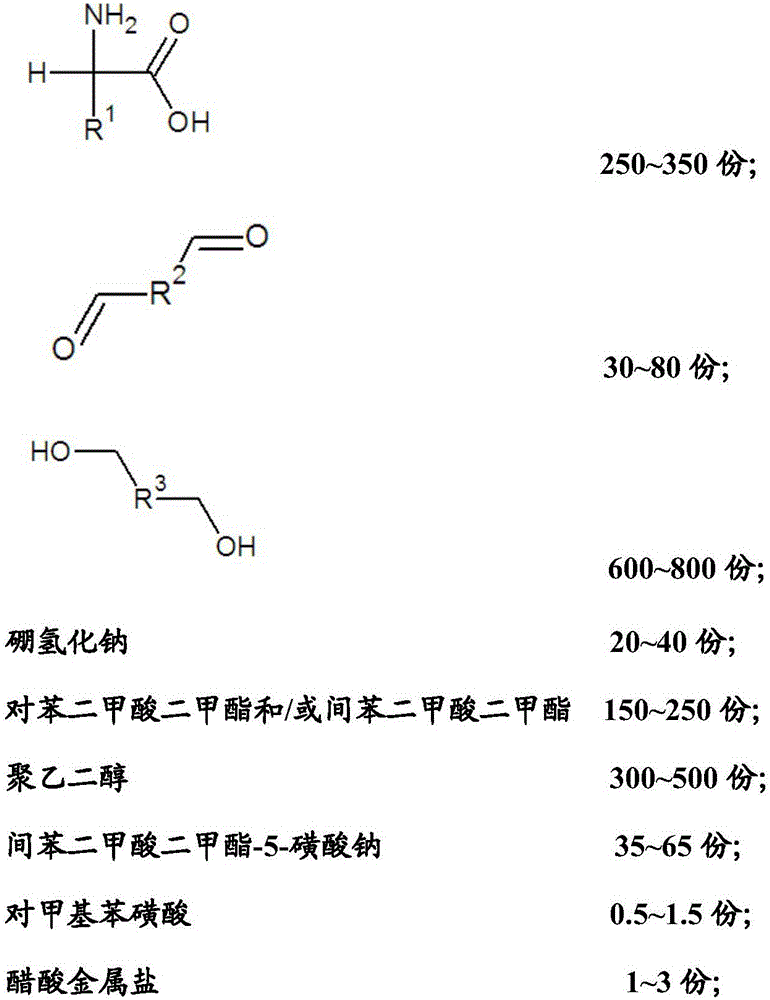

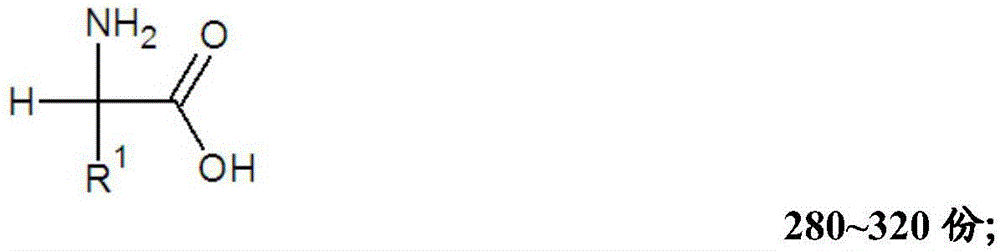

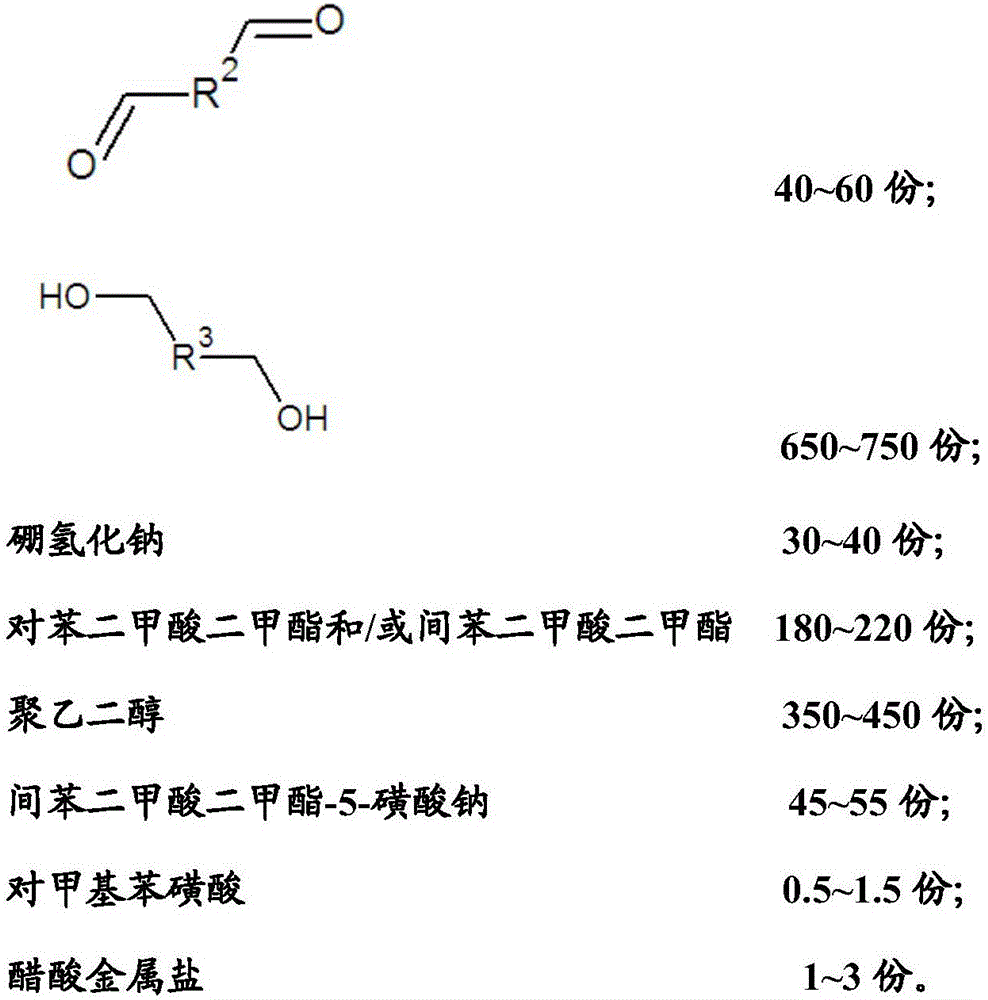

Method used

Image

Examples

Embodiment 1

[0036] At about 30°C, add lysine: 293.38g, glyoxal: 58.04g, ethylene glycol: 700g into the reactor and react for 30min, then add sodium borohydride: 37.83g, and continue the reaction for 30min. Then add dimethyl terephthalate: 194g, dimethyl isophthalate-5-sodium sulfonate: 45g, polyethylene glycol with a molecular weight of 1000: 400g, p-toluenesulfonic acid: 1g, magnesium acetate : 2g, heat up to 150°C for 250 minutes, continue to heat up to 220°C for 90 minutes, then keep the temperature at 280°C for 120min at a vacuum degree of -0.08MP, polymerize into a block copolymer with a number average molecular weight of 18,000, and cool down After reaching 120°C, the material is discharged to obtain the product.

Embodiment 2

[0038] At about 30°C, add lysine: 350g, glyoxal: 45g, ethylene glycol: 750g into the reactor and react for 50 minutes, then add sodium borohydride: 45g, and continue the reaction for 50 minutes. Then add dimethyl terephthalate: 220g, dimethyl isophthalate-5-sodium sulfonate: 55g, polyethylene glycol with a molecular weight of 400: 350g, p-toluenesulfonic acid: 1g, zinc acetate : 2g, heat up to 185°C for 180 minutes, continue to heat up to 220°C for 90 minutes, then keep the temperature at 230°C for 120min at a vacuum degree of -0.1MP, polymerize into a block copolymer with a number average molecular weight of 15,000, and cool down After reaching 100°C, the material is discharged to obtain the product.

Embodiment 3

[0040] At about 30°C, add lysine: 250g, glyoxal: 60g, ethylene glycol: 650g into the reactor and react for 1 hour, then add sodium borohydride: 30g, and continue the reaction for 1 hour. Then add dimethyl isophthalate: 180g, dimethyl isophthalate-5-sodium sulfonate: 50g, polyethylene glycol with a molecular weight of 4000: 450g, p-toluenesulfonic acid: 1g, calcium acetate : 2g, heat up to 170°C for 100 minutes, continue to heat up to 225°C for 80 minutes, then keep the temperature at 250°C for 120min at a vacuum degree of -0.09MP, polymerize into a block copolymer with a number average molecular weight of 17,000, and cool down After reaching 100°C, the material is discharged to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com