Sulfonated graphene-modified sulfur-carbon electrode and preparation and application thereof

A technology of sulfonated graphene and electrodes, which is applied in the field of preparation of sulfur-carbon electrodes, can solve the problems of increasing material preparation costs, complex preparation processes, and insignificant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

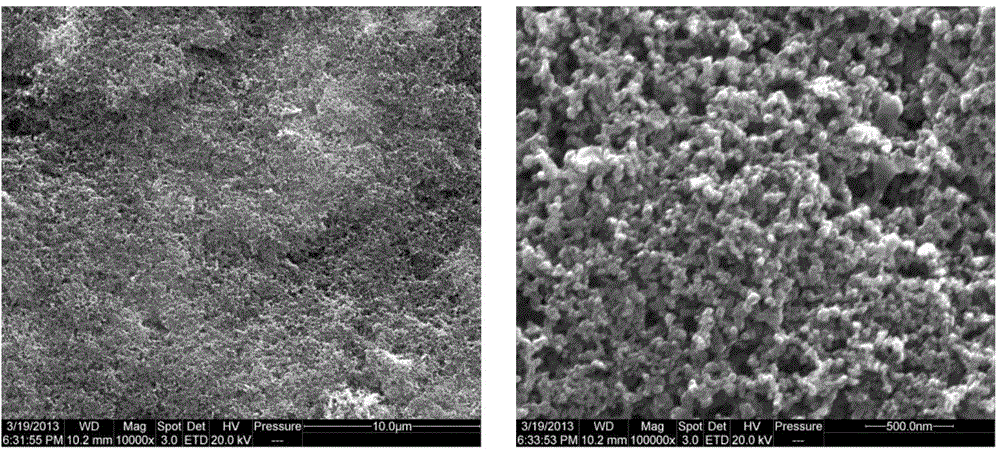

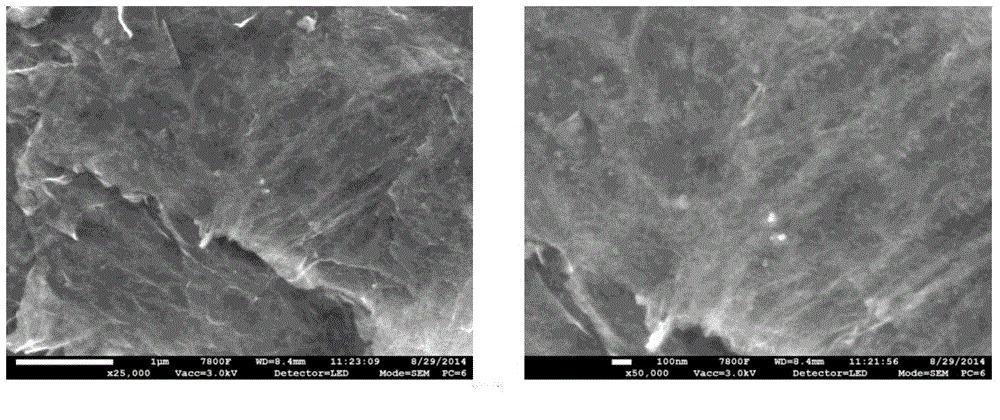

Embodiment 1

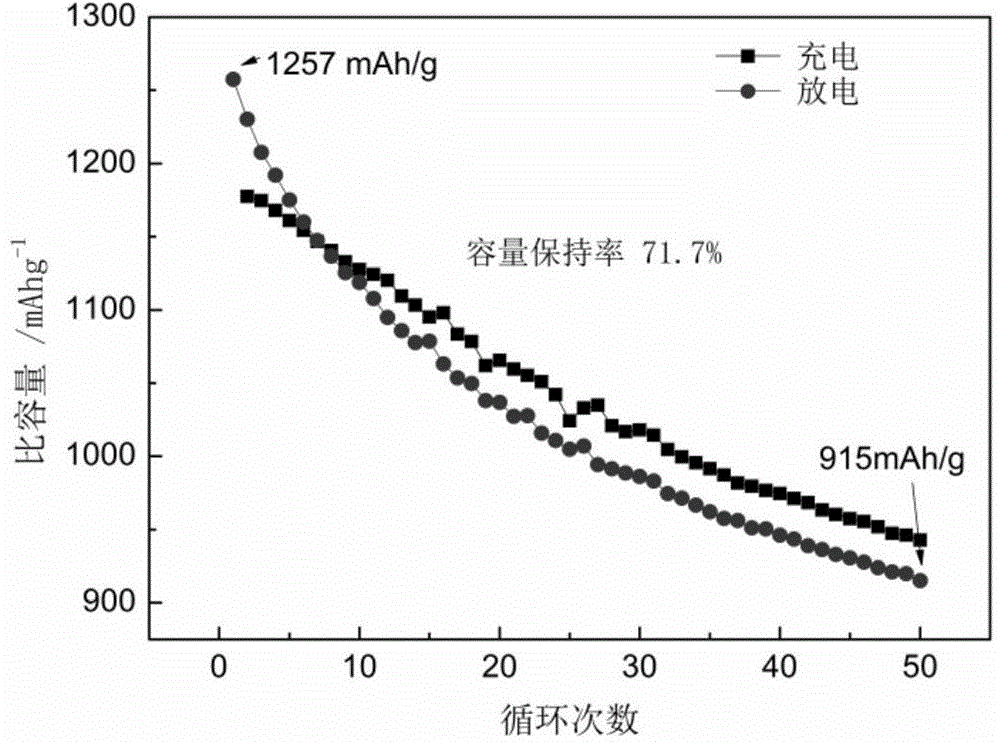

[0021] Take 2 g of sulfonated graphene with a carbon-sulfur element ratio of 6:1, immerse it in 100 ml of lithium hydroxide solution with a mass fraction of 30% for 24 hours, then wash, filter and dry the sulfonated graphene to obtain lithiated sulfonated graphene Graphene. The graphene was uniformly mixed with polytetrafluoroethylene emulsion and water with a mass fraction of 5%, and the specific ratio was 2g sulfonated graphene, 10g polytetrafluoroethylene emulsion and 30ml water. The mixed system is sprayed on the carbon-sulfur composite electrode. The carbon material used in the carbon-sulfur composite electrode is SuperP, the sulfur filling rate is 50%, and the sulfur loading is 2mg / cm 2 . After spraying, the loading of sulfonated graphene is 0.1mg / cm 2 . After the electrode modified by the sulfonated graphene was dried, it was assembled into a lithium-sulfur battery for battery testing. The test conditions are that the current density is 0.1 times, and the charge an...

Embodiment 2

[0023] Take 2 g of sulfonated graphene with a carbon-sulfur element ratio of 9:1, immerse it in 100 ml of lithium hydroxide solution with a mass fraction of 15% for 24 hours, then wash, filter and dry the sulfonated graphene to obtain lithiated sulfonate Graphene. The graphene is uniformly mixed with 5% polyvinylidene fluoride and N-N dimethylacetamide, and the specific ratio is 2g sulfonated graphene, 10g polyvinylidene fluoride solution and 20ml N-N dimethylacetamide. The mixed system is sprayed on the carbon-sulfur composite electrode. The carbon material used in the carbon-sulfur composite electrode is KB600, the sulfur filling rate is 50%, and the sulfur loading is 2mg / cm 2 . After spraying, the loading of sulfonated graphene is 0.1mg / cm 2 . After the electrode modified by the sulfonated graphene was dried, it was assembled into a lithium-sulfur battery for battery testing. The test conditions are that the current density is 0.1 times, and the charge and discharge ra...

Embodiment 3

[0025] Take 2g of sulfonated graphene with a carbon-sulfur element ratio of 8:1, immerse it in 100ml of lithium hydroxide solution with a mass fraction of 20% for 24h, then wash, filter and dry the sulfonated graphene to obtain lithiated sulfonated graphene Graphene. The graphene is uniformly mixed with 5% polyvinylidene fluoride and N-N dimethylacetamide, and the specific ratio is 2g sulfonated graphene, 10g polyvinylidene fluoride solution and 20ml N-N dimethylacetamide. The mixed system is sprayed on the carbon-sulfur composite electrode. The carbon material used in the carbon-sulfur composite electrode is KB600, the sulfur filling rate is 50%, and the sulfur loading is 2mg / cm 2 . After spraying, the loading of sulfonated graphene is 0.1mg / cm 2 . After the electrode modified by the sulfonated graphene was dried, it was assembled into a lithium-sulfur battery for battery testing. The test conditions are that the current density is 0.1 times, and the charge and discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com