A method for preparing high-performance carbon-based catalysts

A carbon-based catalyst, high-performance technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems affecting the activity of carbon-based catalysts, small specific surface area, etc., to achieve reduced content of transition metals, simple preparation process, and reliable performance The effect of regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The method for preparing a high-performance carbon-based catalyst:

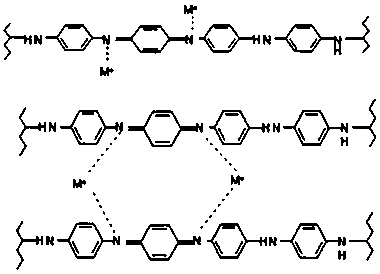

[0046] (1) First prepare the suspension by coordinating aniline with a transition metal salt; the specific process of the step (1) is:

[0047] 1.1. First, divide 250mL of sulfuric acid solution with a concentration of 1mol / L into two parts (one part is 200mL, the other part is 50mL), and one part (200mL) is added with transition metal salt and stirred until completely dissolved, and then passed into N 2 (N 2 0.1mol aniline was added to liquid A at a temperature of 5°C, and ultrasonicated for 60 minutes until the aniline salt solution was completely reacted; another portion (50 mL) was added Ammonium sulfate, stirred for 60min until completely dissolved, then passed into N 2 (N 2 The feed rate is 5ml / min) for 15 minutes to form liquid B, in which the molar ratio of aniline to transition metal salt is 8:1, and the molar ratio of aniline to ammonium persulfate is 5:1; the transition metal salt is ferr...

Embodiment 2

[0054] The method for preparing a high-performance carbon-based catalyst:

[0055] (1) First prepare the suspension by coordinating aniline with a transition metal salt; the specific process of the step (1) is:

[0056] 1.1. First, divide 250mL of sulfuric acid solution with a concentration of 1mol / L into two parts (one part is 200mL, the other part is 50mL), and one part (200mL) is added with transition metal salt and stirred until completely dissolved, and then passed into N 2 (N 2 0.1mol aniline was added to liquid A at a temperature of 5°C, and ultrasonicated for 60 minutes until the aniline salt solution was completely reacted; another portion (50 mL) was added Ammonium sulfate, stirred for 60min until completely dissolved, then passed into N 2 (N 2 The feed rate is 5ml / min) for 15 minutes to form liquid B, in which the molar ratio of aniline to transition metal salt is 8:1, and the molar ratio of aniline to ammonium persulfate is 5:1; the transition metal salt is ferr...

Embodiment 3

[0062] Embodiment 3 (for the comparative experiment of comparative example 1 and embodiment 2)

[0063] The method for preparing a high-performance carbon-based catalyst:

[0064] (1) First, prepare a suspension by coordinating aniline with a transition metal salt; the specific process of the step (1) is:

[0065] 1.1. First, divide 250mL of sulfuric acid solution with a concentration of 1mol / L into two parts (one part is 200mL, the other part is 50mL), and one part (200mL) is added with transition metal salt and stirred until completely dissolved, and then passed into N 2 (N 2 0.1mol aniline was added to liquid A at a temperature of 5°C, and ultrasonicated for 60 minutes until the aniline salt solution was completely reacted; another portion (50 mL) was added Ammonium sulfate, stirred for 60min until completely dissolved, then passed into N 2 (N 2 The feed rate is 5ml / min) for 15 minutes to form liquid B, in which the molar ratio of aniline to transition metal salt is 8:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com