Preparation method of plant protein powder fermented milk beverage

A technology of vegetable protein powder and fermented milk beverages, which is applied in the production field of fermented milk beverages, can solve the problems of unstable quality of fermented yogurt final products, many bad beany smells, food safety problems, etc., to avoid product allergies or Bad flavor, improve product stability, and facilitate digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

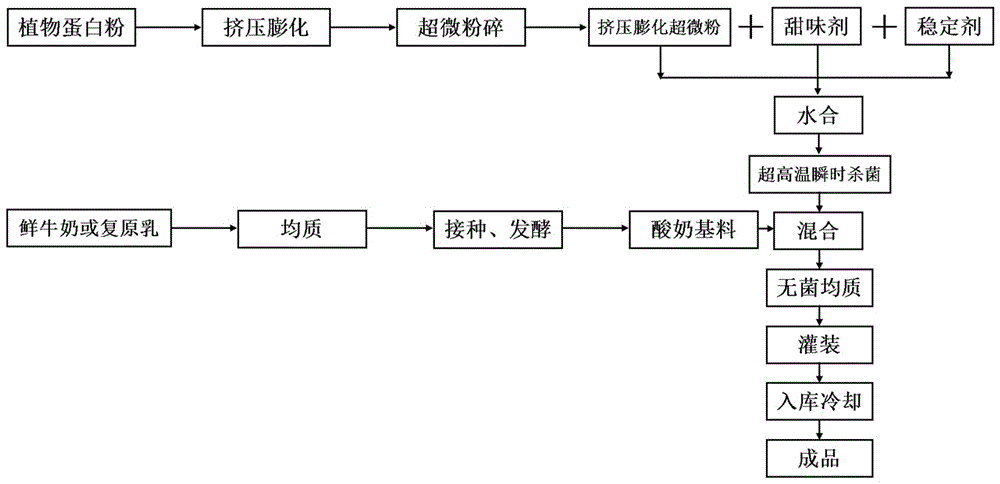

[0034] see figure 1 , the specific operation steps of preparing vegetable protein powder fermented milk drink are as follows:

[0035] (1) Preparation of extruded ultrafine broad bean protein powder:

[0036] Select high-quality broad bean protein powder or broad bean protein isolate powder, adjust the moisture content of the material to 16%, and use the DSE32 twin-screw extrusion extruder for extrusion processing, set the extrusion temperature to 170 ° C, and the host speed to 2000 rpm. The pressure is 1.5 MPa. The puffed product is subjected to micronization treatment by an XDW6 vibrating ultrafine pulverizer, and the ultrafine pulverization time is 35 minutes, and the particle size of the obtained ultrafine pulverization is ≤15 μm.

[0037] (2) Preparation of yogurt base:

[0038] Mix skim milk powder and soft water to prepare reconstituted milk with a mass concentration of 12%. After homogenizing at 18MPa and 65°C, cool to 42°C and inoculate with 6 CFU / mL of Streptococ...

Embodiment 2

[0042] A kind of preparation method of extruded puffed walnut protein powder fermented milk drink of the present invention specifically comprises the following steps:

[0043] (1) Preparation of extruded superfine walnut protein powder:

[0044] Select high-quality walnut protein powder or broad bean protein isolate powder, adjust the moisture content of the material to 11%, use DS32-II twin-screw extruder for extrusion processing, set the extrusion temperature to 160°C, and the host speed to 1600 rpm , The extrusion pressure is 1.2MPa. The puff obtained is subjected to micronization treatment by a YQS type supersonic jet mill, and the ultrafine pulverization time is 10 minutes, and the particle diameter of the obtained ultrafine pulverization is ≤10 μm.

[0045] (2) Preparation of yogurt base:

[0046] Using fresh milk as raw material, adopt standardized treatment, after homogenization at 18MPa and 65°C, cool to 37°C, inoculate with 5×10 6 CFU / mL Lactobacillus paracasei di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com