Flue gas condensation and electrostatic treatment device and treatment technology

A technology of electrostatic treatment and flue gas condensation, which is applied in gas treatment, electrostatic separation, electrostatic effect separation, etc., to achieve the effect of reducing system pollutant emissions, reducing total emissions, and reducing system fuel energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

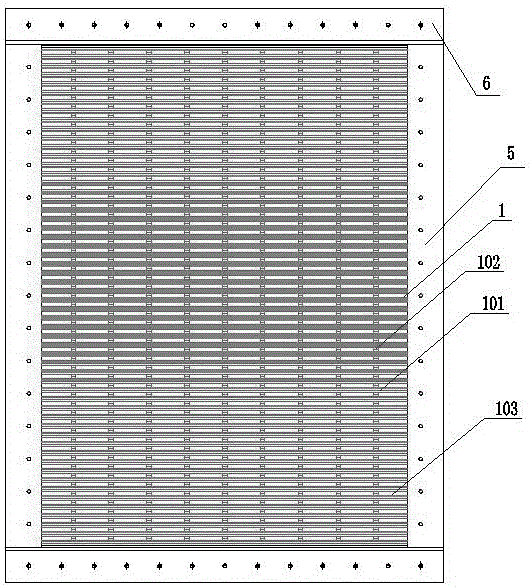

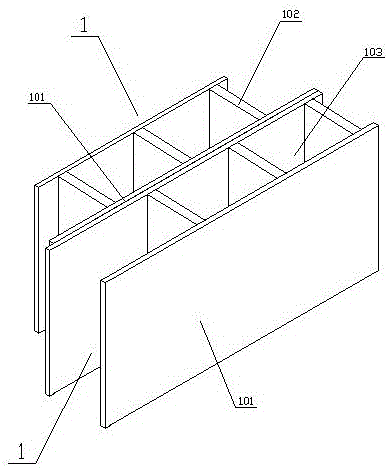

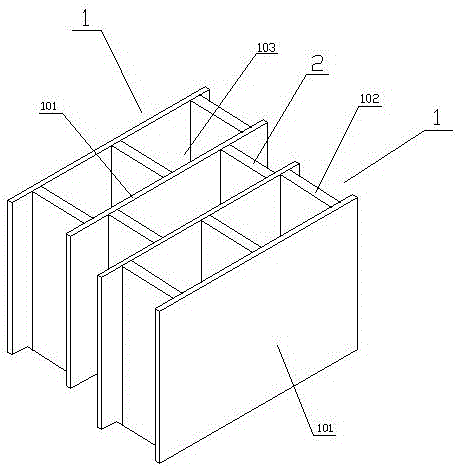

[0036] like Figure 1-5 As shown, an electrostatic treatment device for flue gas condensation, the device is composed of several electrostatic heat exchange modules connected in series or in parallel. The electrostatic heat exchange module includes a frame and several layers of heat exchange units 1 stacked in the frame. Adjacent two-layer heat exchange units 1 are closely attached or supported and fixed by several support members 2, and the support member 2 divides the chamber between adjacent two-layer heat exchange units 1 into several fluid channels 103, each layer exchange The heat unit 1 includes two heat exchange plates 101 corresponding up and down and several partitions 102 arranged between the two heat exchange plates 101, and the spacers 102 also separate the cavity between the two heat exchange plates 101 into a number of fluid channels 103, and then form a multi-layered fluid channel layer, so that the flue gas and the cooling medium respectively circulate in diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com