Fct-phase FePtCu ternary alloy nano particle catalyst and synthesis method thereof

A nanoparticle and ternary alloy technology, which is applied in the field of nanotechnology and catalysis, can solve the problems of nanoparticle agglomeration, achieve low cost, excellent stability and catalytic activity, and avoid the effect of nanoparticle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

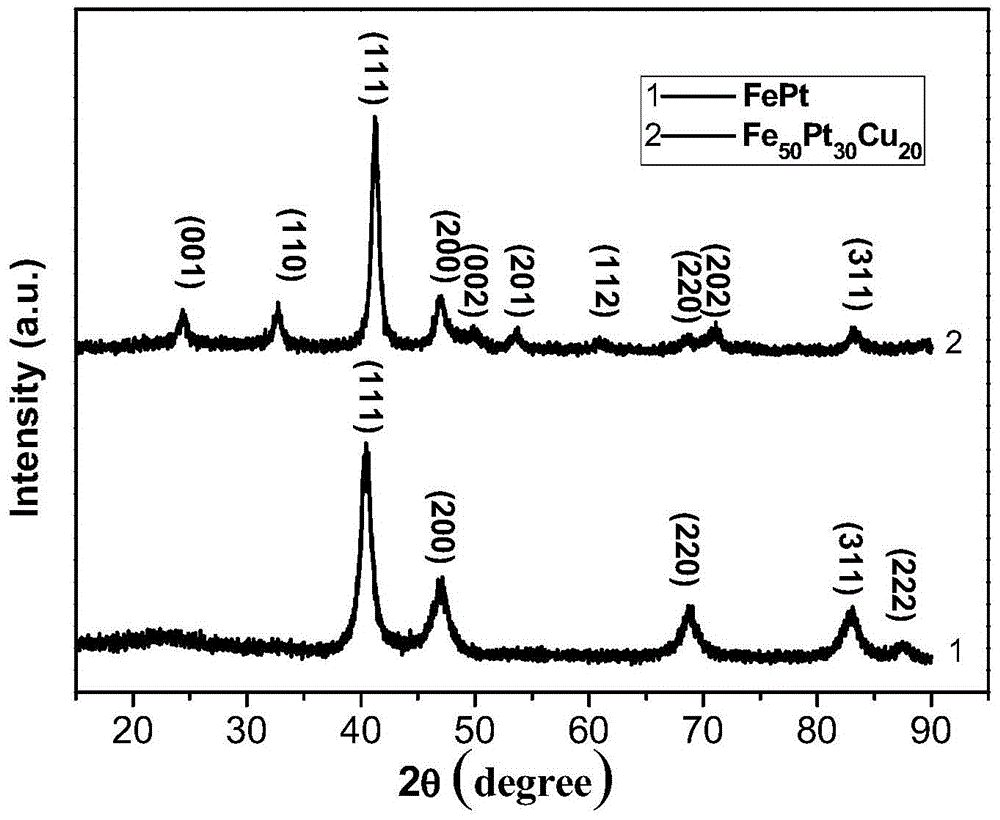

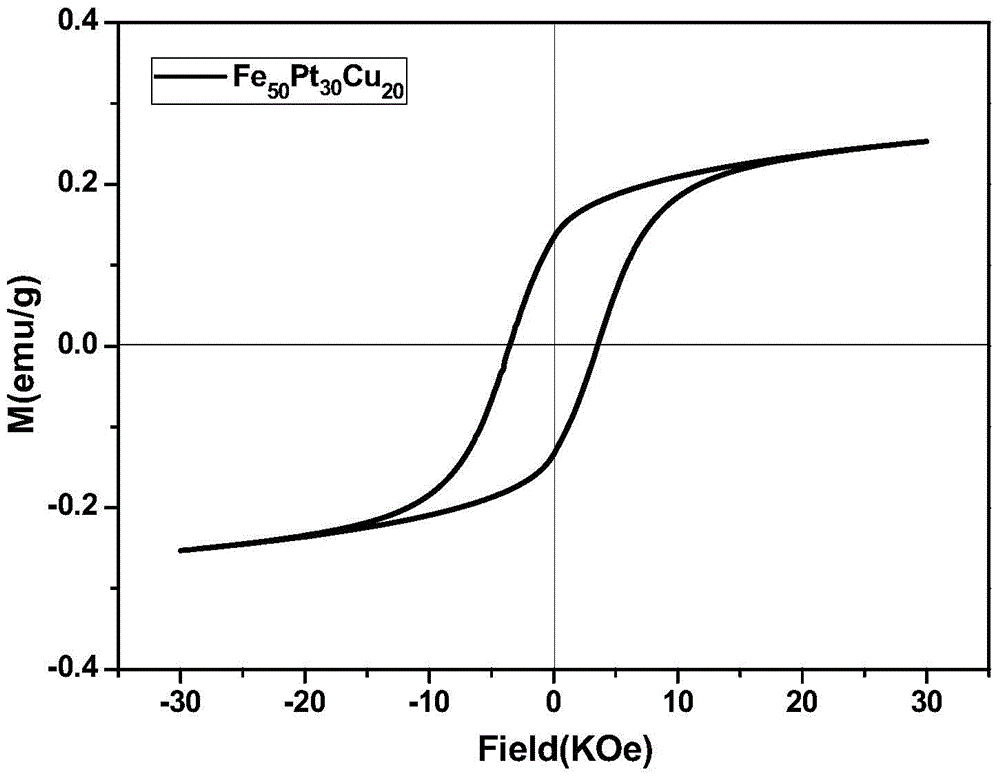

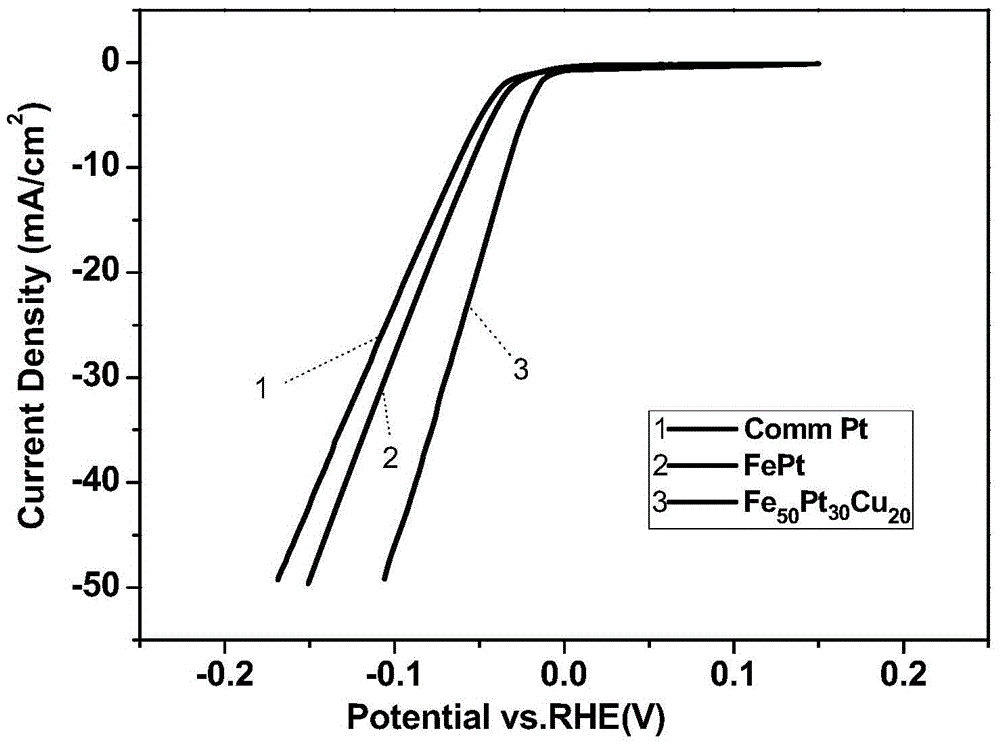

[0043] Example 1 : prepare fct-Fe of the present invention 50 Pt 30 Cu 20 The ternary alloy nano particle catalyst has the percentages of Fe element being 50±2%, Pt element being 30±2%, and Cu element being 20±2%.

[0044] First, the corresponding molar ratio of anhydrous FeCl 2 , platinum acetylacetonate (Pt(acac) 2 ), copper acetylacetonate (Cu(acac) 2 ) as a metal precursor, 1.5mmol1,2-hexadecanediol is mixed as a reducing agent and poured into a 100ml four-necked round-bottomed flask, and 20-25g of high-boiling point organic solvent hexadecylamine is used as a reaction solvent. 2 While heating in the atmosphere, carry out mechanical stirring. When the temperature of the whole mixed solution rises to 110°C, add 1mL of surface modifiers oleic acid and oleylamine after keeping it warm for 10 minutes. After the solution is heated to about 320°C, heat and condense at this temperature. Reflux and maintain mechanical stirring for 2.5 to 3.5 hours.

[0045] Stop heating, l...

Embodiment 2

[0051] Example 2 : prepare fct-Fe of the present invention 30 Pt 50 Cu 20 The ternary alloy nano particle catalyst has the percentages of Fe element being 30±2%, Pt element being 50±2%, and Cu element being 20±2%.

[0052] First, the corresponding molar ratio of anhydrous FeCl 2 , platinum acetylacetonate (Pt(acac) 2 ), copper acetylacetonate (Cu(acac) 2 ) as a metal precursor, 1.5mmol of 1,2-hexadecanediol is mixed as a reducing agent and poured into a 100ml four-neck round-bottomed flask, and 20-25g of a high-boiling point organic solvent hexadecylamine is used as a reaction solvent. N 2 While heating in the atmosphere, carry out mechanical stirring. When the temperature of the whole mixed solution rises to 110°C, add 1mL of surface modifiers oleic acid and oleylamine after keeping it warm for 10 minutes. After the solution is heated to about 320°C, heat and condense at this temperature. Reflux and maintain mechanical stirring for 2.5 to 3.5 hours.

[0053] Stop hea...

Embodiment 3

[0059] Example 3 : prepare fct-Fe of the present invention 35 Pt 45 Cu 20 The ternary alloy nano particle catalyst has a percentage of 35±2% for Fe element, 45±2% for Pt element and 20±2% for Cu element.

[0060] First, the corresponding molar ratio of anhydrous FeCl 2 , platinum acetylacetonate (Pt(acac) 2 ), copper acetylacetonate (Cu(acac) 2 ) as a metal precursor, 1.5mmol1,2-hexadecanediol is mixed as a reducing agent and poured into a 100ml four-necked round-bottomed flask, and 20-25g of high-boiling point organic solvent hexadecylamine is used as a reaction solvent. 2 While heating in the atmosphere, carry out mechanical stirring. When the temperature of the entire mixed solution rises to 110°C, add 1 mL of surface modifier oleic acid and oleylamine after holding for 10 minutes, and heat the solution to about 320°C, then heat and condense at this temperature. Reflux and maintain mechanical stirring for 2.5 to 3.5 hours.

[0061] Stop heating, let the whole mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com