Aluminum electrolytic cell overhaul dreg harmless treatment system and method

A technology of harmless treatment and aluminum electrolytic cell, applied in the direction of solid waste removal, etc., can solve the problems of low efficiency of harmless treatment of electrolytic aluminum overhaul slag, decrease of reaction rate, influence of reaction efficiency, etc., to facilitate continuous treatment , to avoid corrosion of equipment, to meet the effect of emission requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

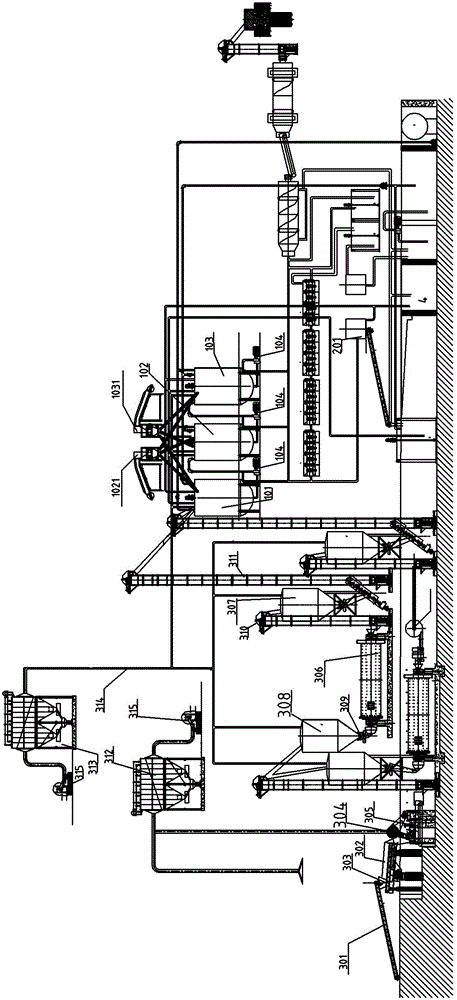

Image

Examples

Embodiment 1

[0055] The method for reclaiming calcium fluoride from aluminum electrolytic cell overhaul slag of the present embodiment comprises the following steps:

[0056] 1) The overhaul slag raw material is transported to the vibrating conveyor through the raw material conveyor belt, the iron in the raw material is removed through the iron removal device on the vibrating conveyor, and sent to the crusher by the vibrating conveyor for crushing, and the crushed raw material is screened , Small raw materials with a diameter of no more than 20mm are sent to the block silo through the elevator, and large raw materials with a diameter larger than 20mm are sent back to the crusher for further crushing; small raw materials in the block silo are sent to the ball mill through the electromagnetic vibrating feeder for further crushing. The raw material fine powder is made by ball milling, sieved, and the raw material fine powder after sifting out impurities such as aluminum lumps and iron lumps is...

Embodiment 2

[0063] The method for reclaiming calcium fluoride from aluminum electrolytic cell overhaul slag of the present embodiment comprises the following steps:

[0064] 1) The overhaul slag raw material is transported to the vibrating conveyor through the raw material conveyor belt, the iron in the raw material is removed through the iron removal device on the vibrating conveyor, and sent to the crusher by the vibrating conveyor for crushing, and the crushed raw material is screened , Small raw materials with a diameter of no more than 20mm are sent to the block silo through the elevator, and large raw materials with a diameter larger than 20mm are sent back to the crusher for further crushing; small raw materials in the block silo are sent to the ball mill through the electromagnetic vibrating feeder for further crushing. The raw material fine powder is made by ball milling, sieved, and the raw material fine powder after sifting out impurities such as aluminum lumps and iron lumps is...

Embodiment 3

[0071] The method for reclaiming calcium fluoride from aluminum electrolytic cell overhaul slag of the present embodiment comprises the following steps:

[0072] 1) The overhaul slag raw material is transported to the vibrating conveyor through the raw material conveyor belt, the iron in the raw material is removed through the iron removal device on the vibrating conveyor, and sent to the crusher by the vibrating conveyor for crushing, and the crushed raw material is screened , Small raw materials with a diameter of no more than 20mm are sent to the block silo through the elevator, and large raw materials with a diameter larger than 20mm are sent back to the crusher for further crushing; small raw materials in the block silo are sent to the ball mill through the electromagnetic vibrating feeder for further crushing. The raw material fine powder is made by ball milling, sieved, and the raw material fine powder after sifting out impurities such as aluminum lumps and iron lumps is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com