Method for preparing black silicon on doped film layer

A technology of doping silicon and black silicon, which is applied in the manufacture of final products, sustainable manufacturing/processing, electrical components, etc., and can solve the problems of cumbersome wet etching steps, toxic waste gas, waste liquid, and low shape accuracy , to achieve the effect of enriching the types of doping elements, increasing the doping concentration and reducing the cost of doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the drawings.

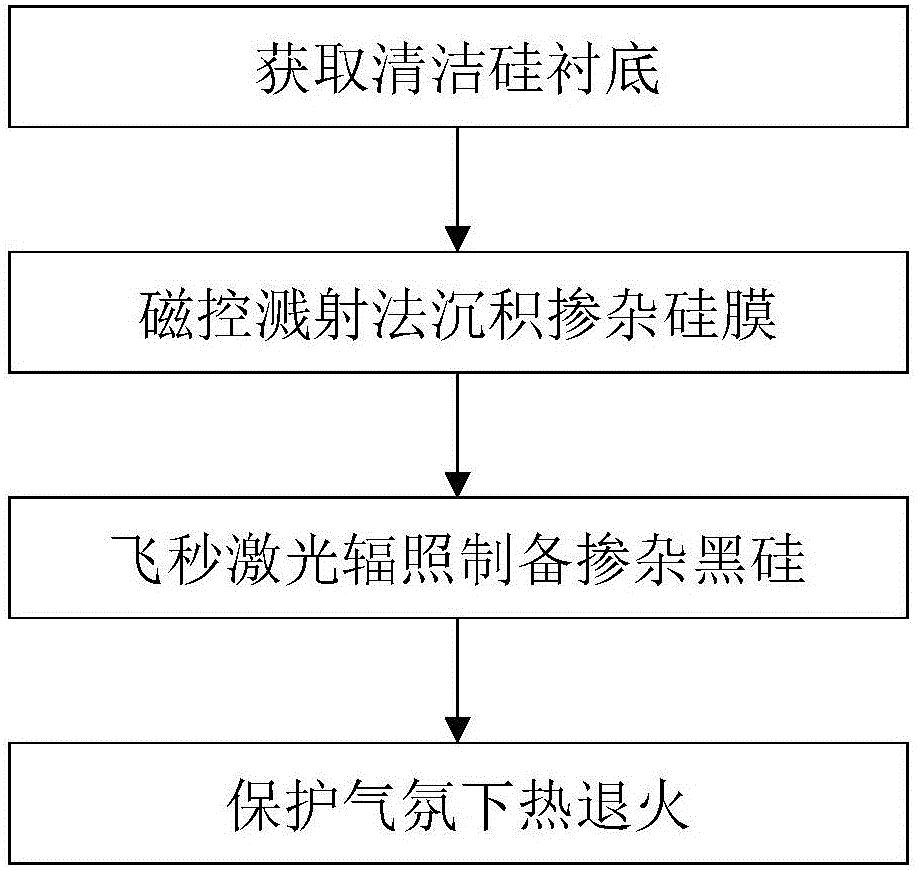

[0023] Such as figure 1 As shown, the preparation of the doped black silicon material in the present invention is to prepare the doped black silicon microstructure by means of femtosecond laser irradiation after preparing the doped film. The specific steps are as follows:

[0024] Step 1: Obtain a clean silicon substrate

[0025] A silicon substrate with a size of 10 mm×10 mm was sonicated for 15 minutes in each of the three solutions in sequence to wash off the oil, particles and oxides on the surface of the substrate. The three solutions are: No. I cleaning solution is concentrated sulfuric acid (H 2 SO 4 ) And 9.7mol / L hydrogen peroxide (H 2 O 2 ), the volume ratio is 5:1; the cleaning solution II is deionized water (H 2 O), hydrogen peroxide (H 2 O 2 ) And 13.3mol / L ammonia (NH 3 ·H 2 O), the volume ratio is 5:2:1; the cleaning solution III is deionized water (H 2 O), the concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com