Waxberry sesame seed candy and production method thereof

A production method, sesame candy technology, applied in confectionary, confectionery industry, cocoa, etc., can solve the problems of food and production methods that have not been researched, do not conform to Chinese traditional eating habits, and have no rich taste, etc., to achieve inhibition Effects of lipid peroxidation and platelet aggregation, vision protection, and high medicinal value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

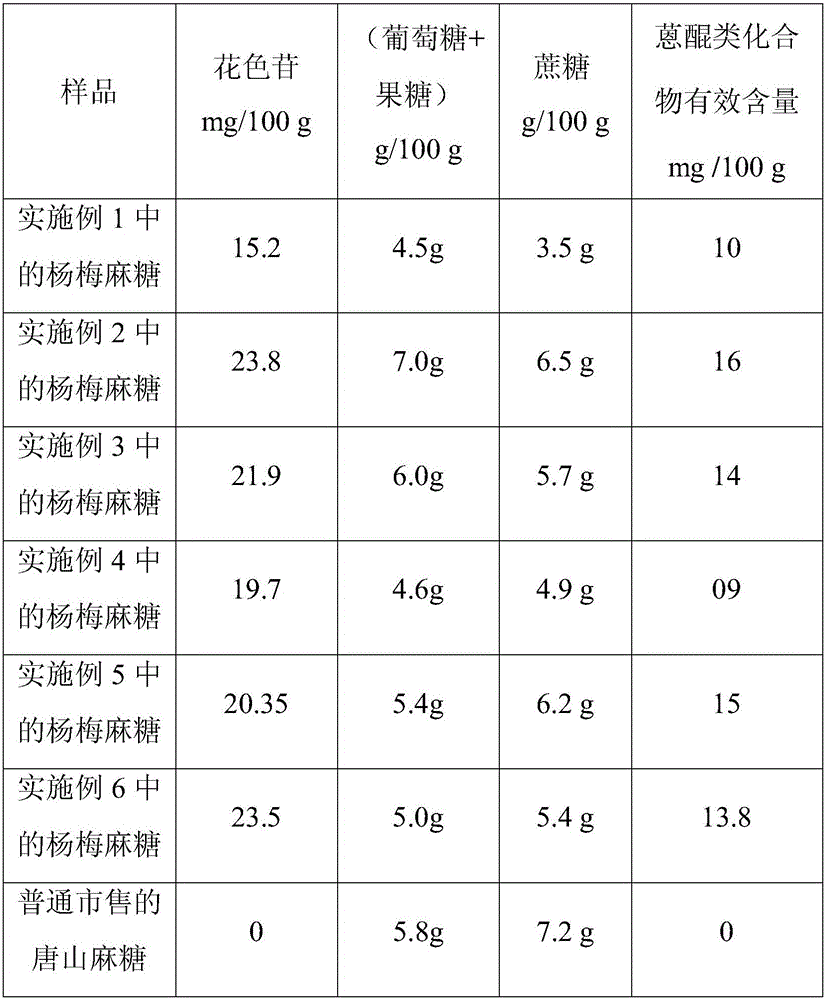

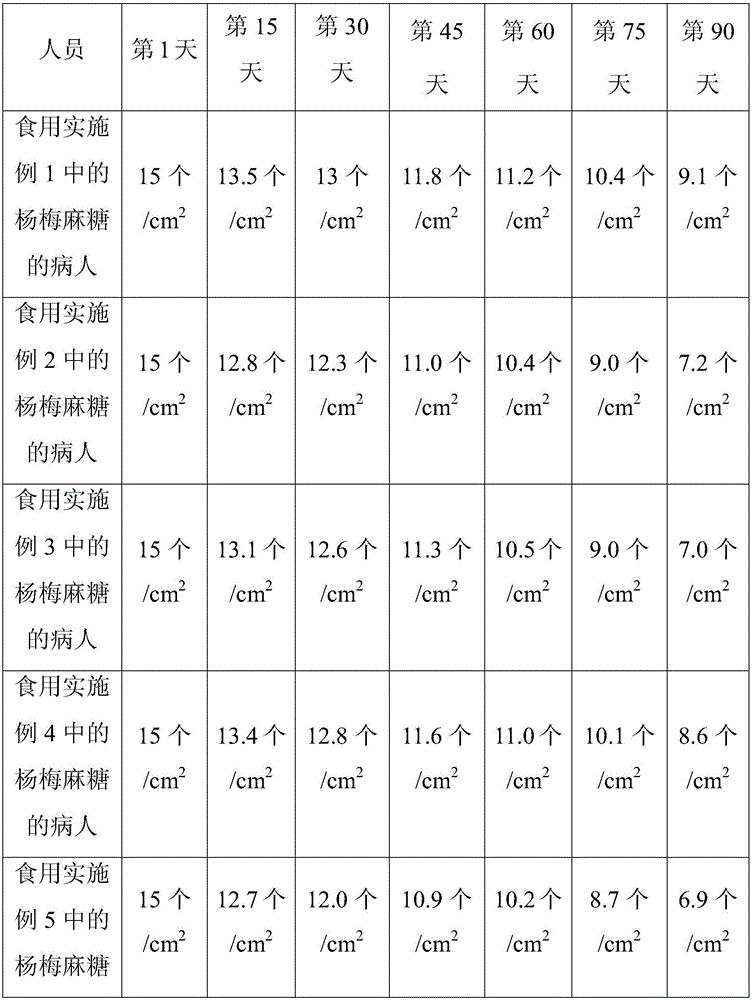

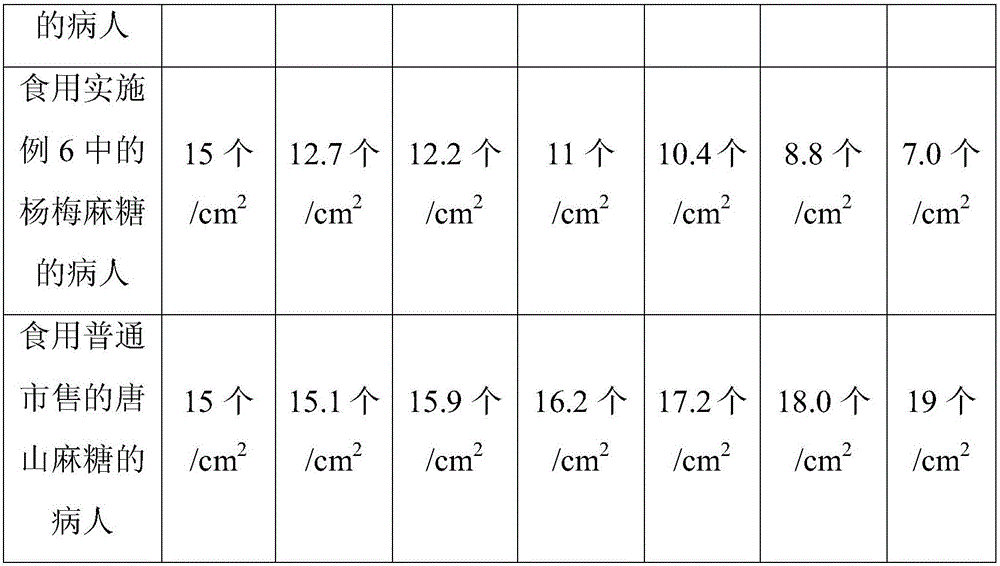

Examples

Embodiment 1

[0032] A kind of bayberry sesame candy, the raw materials to be made include: 100 parts of flour, 100 parts of glutinous rice flour, 50 parts of white sugar, 50 parts of bayberry powdered sugar, 30 parts of honey, 30 parts of olive oil, 25 parts of rose petals, and 20 parts of figs , 20 parts of pomelo pulp, 2 parts of sealwort powder. Wherein the production process of red bayberry powdered sugar is specifically: wash the fresh red bayberry and soak it in ethanol solution for 3 hours, pick out the red bayberry with good composition, dry it in the air under dry conditions, and make the ethanol volatilize, and then cut the obtained red bayberry into fine cubes of 1 mm. Then put the red bayberry fine diced into a vacuum drying box and carry out vacuum drying for 3 hours. After taking it out, the product is ground into powder, and the powder passing through a 150-mesh sieve is red bayberry sugar powder. Wherein, the temperature of vacuum drying is 30° C., and the vacuum pressure i...

Embodiment 2

[0034] A kind of bayberry sesame candy, the raw materials to be made include: 500 parts of flour, 500 parts of glutinous rice flour, 150 parts of white granulated sugar, 150 parts of bayberry powdered sugar, 80 parts of honey, 100 parts of olive oil, 80 parts of rose petals, and 50 parts of figs , 50 parts of pomelo pulp, 5 parts of sealwort powder. Wherein the production process of red bayberry powdered sugar is specifically: wash the fresh red bayberry and soak it in ethanol solution for 5 hours, pick out the red bayberry with good composition, dry it in the air under dry conditions, and make the ethanol volatilize, and then cut the gained bayberry into 3mm fine cubes, Then put the red bayberry finely diced into a vacuum drying box and carry out vacuum drying for 6 hours, and after taking it out, grind the product into powder, and the powder passing through a 150-mesh sieve is red bayberry sugar powder. Wherein, the temperature of vacuum drying is 45° C., and the vacuum pres...

Embodiment 3

[0036]A kind of bayberry sesame candy, the raw materials to be made include: 300 parts of flour, 300 parts of glutinous rice flour, 100 parts of white granulated sugar, 100 parts of bayberry powdered sugar, 55 parts of honey, 65 parts of olive oil, 52 parts of rose petals, and 35 parts of figs , 35 parts of pomelo pulp, 3.5 parts of Polygonatum powder. Wherein the production process of red bayberry powdered sugar is specifically: wash the fresh red bayberry and soak it in the ethanol solution for 4 hours, pick out the red bayberry with good composition, dry it in the air under dry conditions, and make the ethanol volatilize, and then cut the obtained red bayberry into fine cubes of 2mm. Then put the red bayberry finely diced into a vacuum drying box and carry out vacuum drying for 4.5 hours. After taking it out, the product is ground into powder, and the powder passing through a 150-mesh sieve is red bayberry sugar powder. Wherein, the temperature of vacuum drying is 37° C., a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com