Low concentration, large wind volume and high odor waste gas concentration energization equipment and technology thereof

A high-volume, low-concentration technology, applied in lighting and heating equipment, incinerators, chemical instruments and methods, etc., can solve the problem of low adsorption efficiency of organic waste gas, achieve high heat exchange efficiency and energy utilization rate, and reduce operating costs , the effect of supplementing less calories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

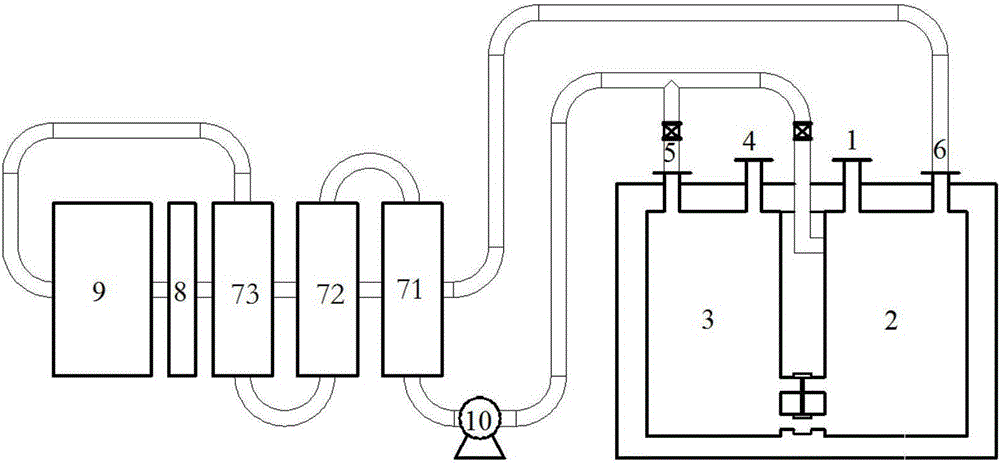

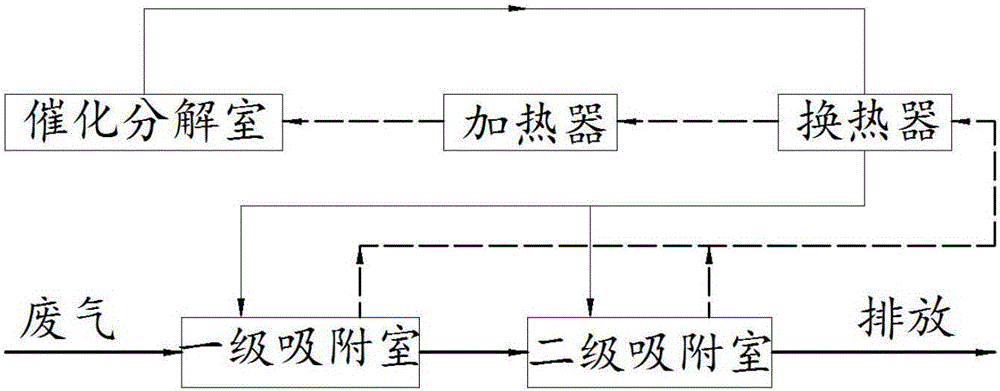

[0055] combine Figure 1-2 , a low-concentration, high-volume, high-odor waste gas concentration energy device, including a waste gas inlet 1, an adsorption-desorption chamber and a catalytic decomposition chamber 9, and also includes a heat exchanger, a heater 8 and an internal circulation fan 10, wherein , the adsorption and desorption chamber is provided with adsorbent, and the adsorption and desorption chamber is provided with waste gas inlet 1, desorption gas outlet 6, exhaust port 4 and desorption gas inlet 5, desorption gas inlet 5 and internal circulation fan One end of 10 is connected through a pipeline, and the adsorption-desorption chamber includes a primary adsorption-desorption chamber 2 and a secondary adsorption-desorption chamber 3, and a desorption gas inlet 5, waste gas inlet 1 and desorption gas outlet 6 are all located at On the primary adsorption-desorption chamber 2 , the primary adsorption-desorption chamber 2 communicates with the secondary adsorption-d...

Embodiment 2

[0068] This embodiment is similar to Embodiment 1, except that the number of heat exchanger stages is adjustable, and the number of heat exchanger stages is determined according to the temperature of the gas after heat exchange, and the temperature range of the gas after heat exchange is 200°C.

[0069] A low-concentration, high-volume, high-odor waste gas concentration and energy conversion process. The desorbed low-temperature mixed gas in step E passes through the primary heat exchanger 71, the secondary heat exchanger 72, the tertiary heat exchanger 73 and heating The device 8 heats up to the catalytic decomposition temperature, the temperature range is 380° C., and enters the catalytic decomposition chamber 9 for combustion.

Embodiment 3

[0071] This embodiment is similar to Embodiment 1, except that the number of heat exchangers is adjustable, and the number of heat exchangers is determined according to the temperature of the gas after heat exchange, and the temperature range of the gas after heat exchange is 100°C.

[0072] A low-concentration, high-volume, high-odor waste gas concentration and energy conversion process. The desorbed low-temperature mixed gas in step E passes through the primary heat exchanger 71, the secondary heat exchanger 72, the tertiary heat exchanger 73 and heating The device 8 heats up to the catalytic decomposition temperature, the temperature range is 350° C., and enters the catalytic decomposition chamber 9 for combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com