Sewage adsorbent based on oily dross and usage thereof

An adsorbent and scum technology, which is applied in the fields of adsorbed water/sewage treatment, other chemical processes, mining wastewater treatment, etc., can solve the problems of difficult oily scum treatment, and achieves low production cost, simple preparation method and wide applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

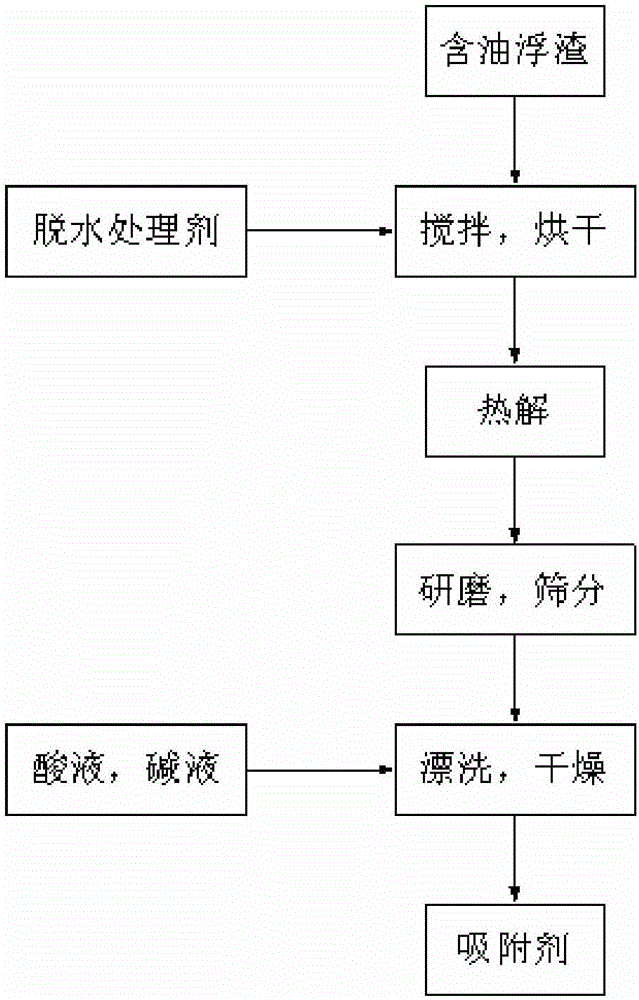

[0019] The preparation method of the sewage adsorbent based on oily scum provided in this embodiment is as follows: figure 1 Shown: The dehydration scum of the flotation tank of a sewage treatment plant in an oil field joint station is the first choice, and the water content is 85.4%, and the oil content is 8.1%. Add a dehydration treatment agent to the above-mentioned oily scum at a mass ratio of 2:1, and mix and stir Dry to obtain solid scum, and the dehydrating agent is a mixture of sulfate agents and activated carbon powder. The solid scum is pyrolyzed at 650°C for 2 hours, nitrogen protection is passed during the pyrolysis process, and the non-condensable gas, oil and water separated during the pyrolysis are recycled for recycling. After the reaction, the solid residue is ground and sieved, rinsed with acid and lye to remove oxides and ash, and then dried to obtain the adsorbent.

[0020] The sewage adsorbent prepared in this example adopts the static adsorption method w...

Embodiment 2

[0022] The preparation method of the sewage adsorbent based on oily scum provided in this embodiment is as follows: figure 1 Shown: The dehydration scum of a sewage treatment station of an oil refinery is the first choice, and the water content is 86.3%, and the oil content is 7.7%. Add a dehydration treatment agent to the above oily scum at a mass ratio of 2:1, mix and stir, and then dry to prepare Get solid scum. The solid scum is pyrolyzed at 600°C for 3 hours, nitrogen protection is passed during the pyrolysis process, and the non-condensable gas, oil and water separated during pyrolysis are recycled for recycling. After the reaction, the solid residue is ground and sieved, rinsed with inorganic acid solution and inorganic alkali solution to remove oxides and ash, and then dried to obtain the adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com