Preparation method of full porous silica microparticle chiral chromatography packing

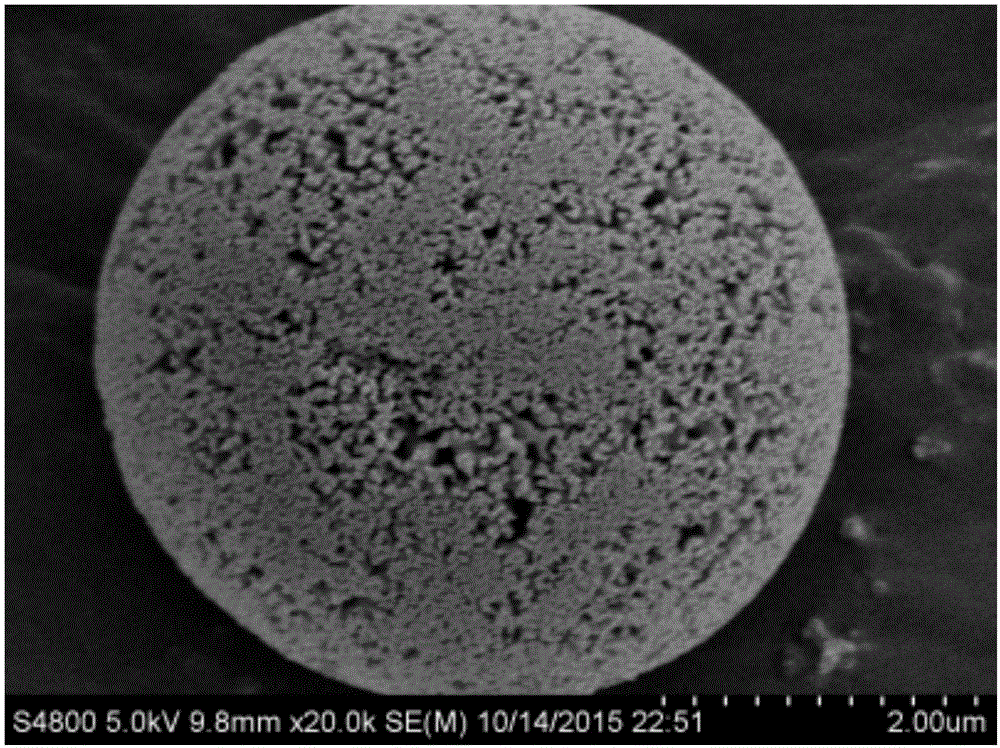

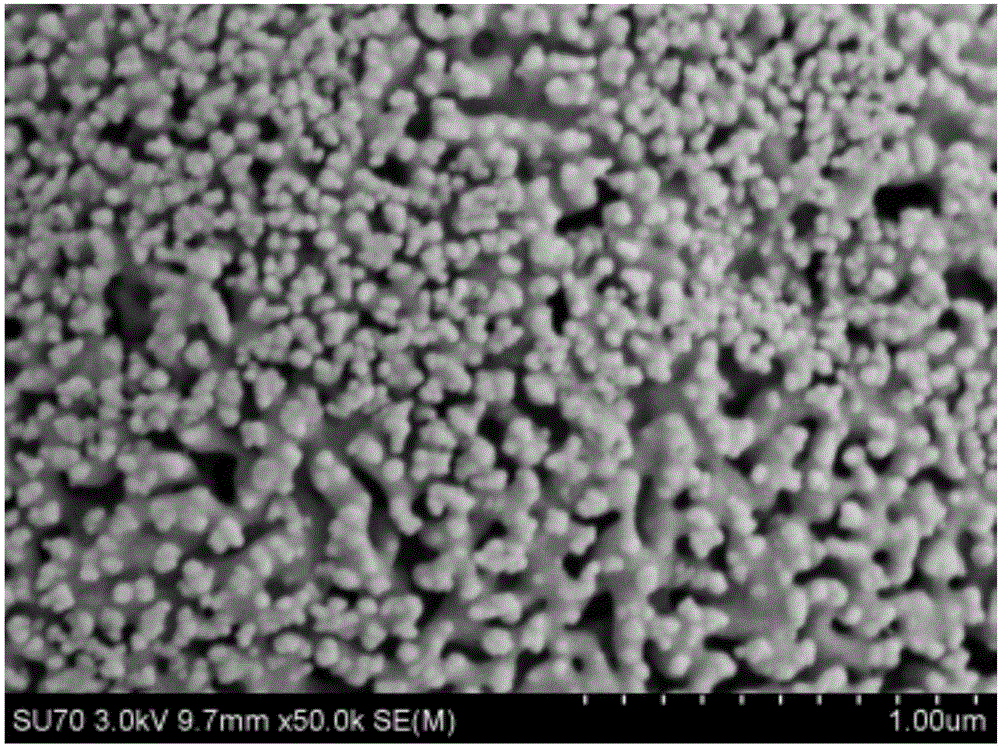

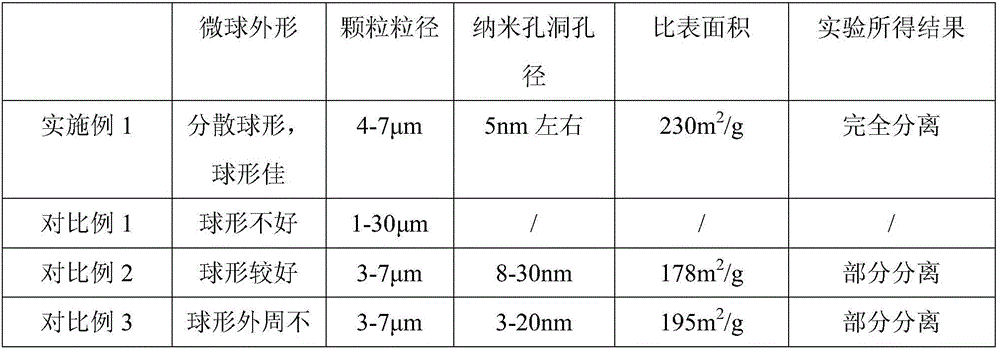

A silica gel microsphere and chiral chromatography technology is applied in the field of preparation of porous microsphere chromatographic fillers, which can solve the problems of different sizes and poor shape of microspheres, and achieve the effects of simple steps, good spheroidization and high porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1. A preparation method of a fully porous silica gel microsphere chiral chromatographic packing, followed by the following steps:

[0037] 1) Add 50g of tetraethoxysilane to 100g of absolute ethanol, stir in a three-necked flask at 30°C for 30 minutes, then add 1.5g of cyclohexane as a stabilizer and polyethylene as a porogen Alcohol (its molecular weight is 400) 7.5g, after mixing well, add 0.1g / ml hydrochloric acid solution to control the pH at 2, continue to stir for 60 minutes and raise the temperature to 90°C to evaporate the absolute ethanol, and then pass it in Argon, keep the temperature (90°C) and stir for 24 hours under the protection of argon, and finally raise the temperature to 140°C to evaporate the remaining liquid organics to obtain polyethoxysilane;

[0038] 2). Mix 30g of the polyethoxysilane obtained in step 1) with 30g of deionized water and 60g of absolute ethanol, add 0.1g / ml of hydrochloric acid to control the pH of the solution at 2, and mix t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com