Preparation method of waterproof polytetrafluoroethylene thin film

A polytetrafluoroethylene film technology, which is applied in the field of waterproof polytetrafluoroethylene film preparation, can solve the problems of uneven air permeability and uneven thickness of the film, and achieve the effects of shortening heating time, reducing processing procedures, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

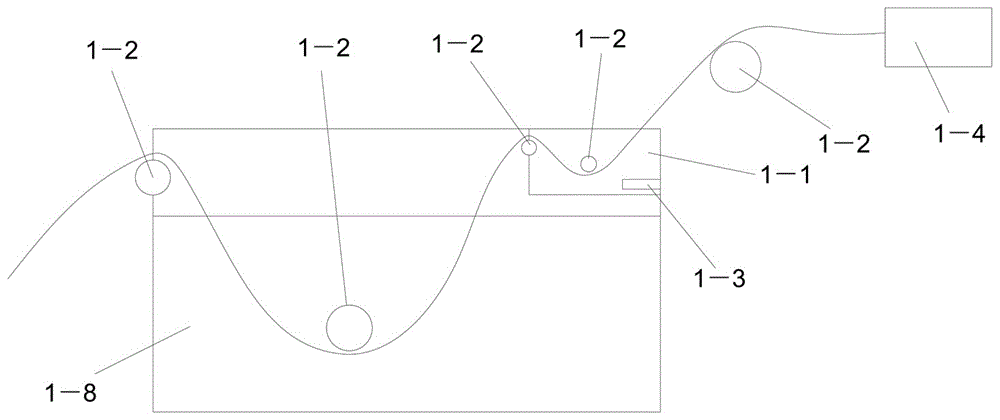

Image

Examples

Embodiment 1

[0034] A kind of preparation method of waterproof polytetrafluoroethylene film, comprises the following steps successively:

[0035] (1) Mixing: Stir and mix polytetrafluoroethylene resin powder, liquid paraffin, and nano-silica powder with a mass ratio of 1:0.2:0.15, and let stand at 30°C for 12 hours to form polytetrafluoroethylene Material; wherein the polytetrafluoroethylene resin powder has a crystallinity of 97% and a molecular weight of 10,000. The preparation method of nano-silica powder is as follows: put nano-silica powder, ethanol, toluene, and silane coupling agent in a closed container at 50°C in a mass ratio of 1:4:0.5:0.3, and stir for 10 hours to obtain a suspension The turbid liquid was suction-filtered and dried to obtain a nano-silica hydrophobic material.

[0036] (2) Compacting and calendering: the polytetrafluoroethylene material is pressed into a cylindrical blank through a compacting machine at 30°C, and the blank is extruded into a rod at a temperatur...

Embodiment 2

[0040] A kind of preparation method of waterproof polytetrafluoroethylene film, comprises the following steps successively:

[0041] (1) Mixing: Stir and mix polytetrafluoroethylene resin powder, petroleum ether, and nano-silica powder with a mass ratio of 1:0.25:0.17, and let stand at 50°C for 18 hours to form polytetrafluoroethylene Material; wherein the polytetrafluoroethylene resin powder has a crystallinity of 98% and a molecular weight of 100,000. The preparation method of nano-silica powder is as follows: put nano-silica powder, ethanol, toluene, and silane coupling agent in a closed container at 30°C in a mass ratio of 1:2:0.2:0.1, stir for 8 hours, and obtain a suspension The turbid liquid was suction-filtered and dried to obtain a nano-silica hydrophobic material.

[0042] (2) Compacting and calendering: The polytetrafluoroethylene material is pressed into a cylindrical blank through a compacting machine at 40°C, and the blank is extruded into a rod at a temperature...

Embodiment 3

[0046] (1) Mixing: Stir and mix polytetrafluoroethylene resin powder, kerosene, and nano-silica powder with a mass ratio of 1:0.3:0.18, and let stand at 70°C for 24 hours to form a polytetrafluoroethylene material ; Among them, the crystallinity of the polytetrafluoroethylene resin powder is 99%, and the molecular weight is 1 million. The preparation method of nano-silica powder is as follows: put nano-silica powder, ethanol, toluene, and silane coupling agent in a closed container at 40°C in a mass ratio of 1:3:0.4:0.2, and stir for 10 hours to obtain a suspension The turbid liquid was suction-filtered and dried to obtain a nano-silica hydrophobic material.

[0047] (2) Compacting and calendering: the polytetrafluoroethylene material is pressed into a cylindrical blank through a compacting machine at 50°C, and the blank is extruded into a rod at a temperature of 60°C through a pusher, and then Calendered at 80°C by a calender to form a polytetrafluoroethylene base tape;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com