Beta molecular sieve with adjustable relative content of polymorphs and synthetic method thereof

A technology of relative content and synthesis method, applied in the field of Beta zeolite molecular sieve preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

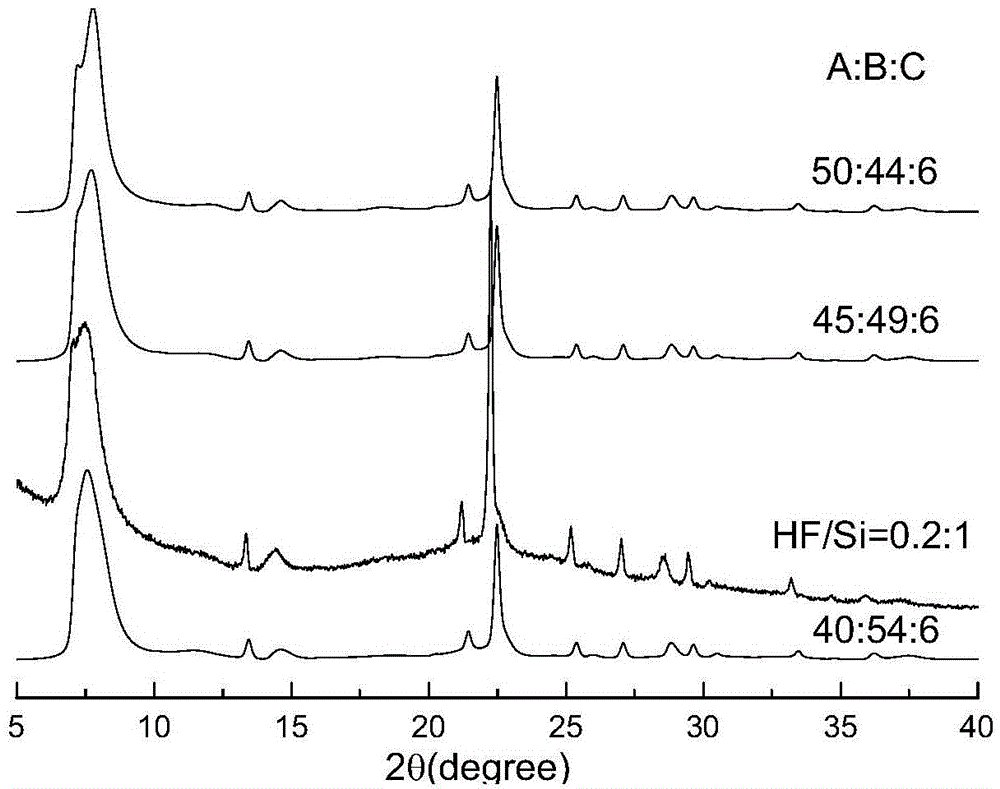

[0050] Beta molecular sieves with adjustable relative content of polymorphs were synthesized under the condition that the molar ratio of fluorine source to silicon source was 0.2:1.

[0051] Add 7.27g of N-isobutyl-N-methylpyrrole hydroxide aqueous solution with a mass fraction of 43.73% into the beaker, then add 15g of deionized water and 8.33g of tetraethyl silicate, and stir at room temperature for 3 Hours, then continue stirring in a constant temperature water bath at 60°C to promote the hydrolysis of tetraethyl silicate until the molar ratio of water to silicon source reaches 4:1 to form a gel, and at this time, add hydrogen with a mass fraction of 40% to the gel drop by drop 0.50g of hydrofluoric acid, stirred evenly, transferred to a 30ml polytetrafluoroethylene-lined stainless steel hydrothermal kettle and crystallized in an oven at 175°C for 7 days. After the crystallization was completed, the product was taken out and washed with deionized water until neutral. Transf...

Embodiment 2

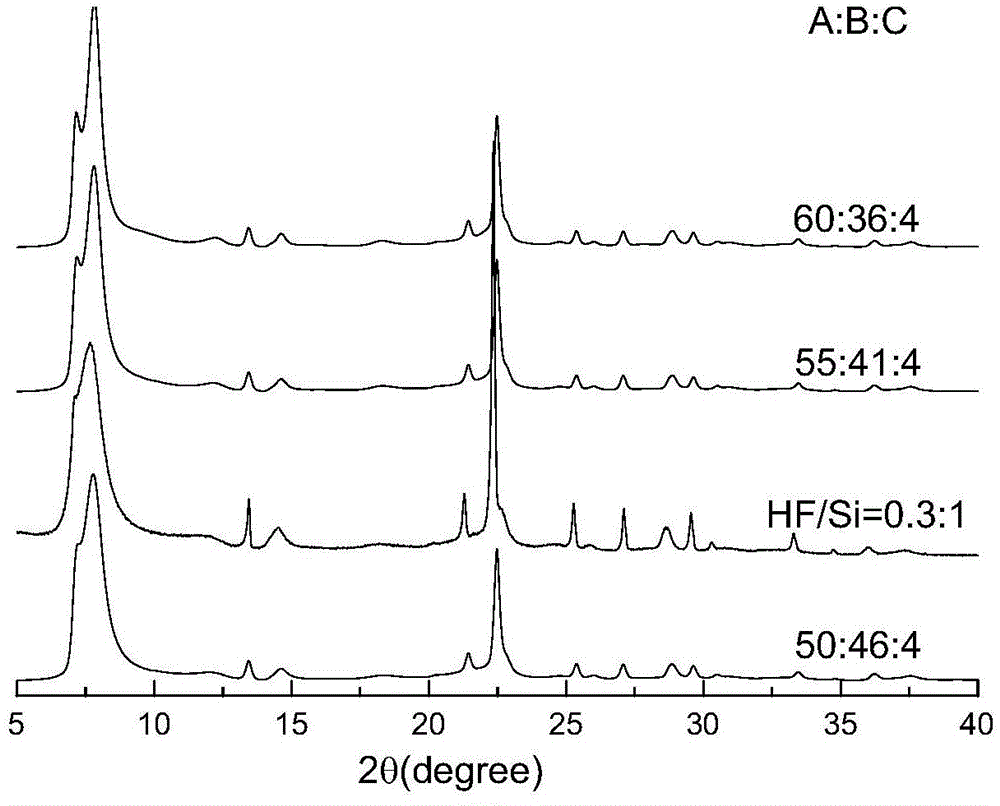

[0054] Beta molecular sieves with adjustable relative content of polymorphs were synthesized under the condition that the molar ratio of fluorine source to silicon source was 0.3:1:

[0055] Add 7.27g of N-isobutyl-N-methylpyrrole hydroxide aqueous solution with a mass fraction of 43.73% into the beaker, then add 15g of deionized water and 8.33g of tetraethyl silicate, and stir at room temperature for 3 Hours, then continue stirring in a constant temperature water bath at 60°C to promote the hydrolysis of tetraethyl silicate until the molar ratio of water to silicon source reaches 4:1 to form a gel, and at this time, add hydrogen with a mass fraction of 40% to the gel drop by drop 0.75g of hydrofluoric acid, stirred evenly, transferred to a 30ml polytetrafluoroethylene-lined stainless steel hydrothermal kettle and crystallized in an oven at 175°C for 7 days. After the crystallization was completed, the product was taken out and washed with deionized water until neutral. Transf...

Embodiment 3

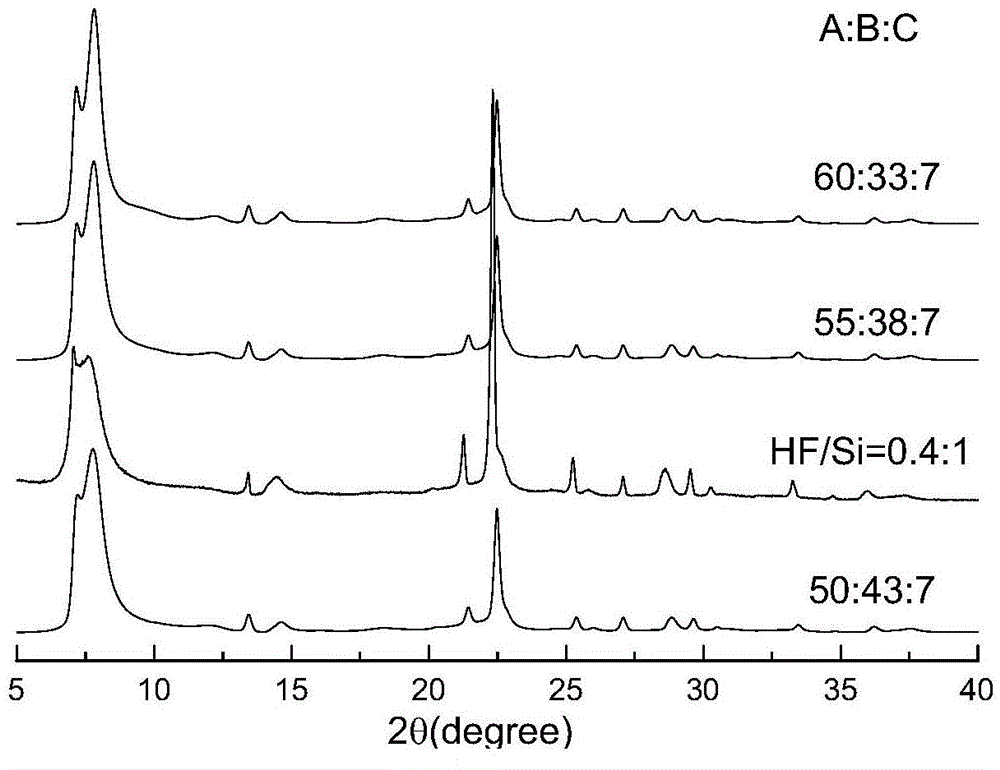

[0058] Beta molecular sieves with adjustable relative content of polymorphs were synthesized under the condition that the molar ratio of fluorine source to silicon source was 0.4:1:

[0059] Add 7.27g of N-isobutyl-N-methylpyrrole hydroxide aqueous solution with a mass fraction of 43.73% into the beaker, then add 15g of deionized water and 8.33g of tetraethyl silicate, and stir at room temperature for 3 Hours, then continue stirring in a constant temperature water bath at 60°C to promote the hydrolysis of tetraethyl silicate until the molar ratio of water to silicon source reaches 4:1 to form a gel, and at this time, add hydrogen with a mass fraction of 40% to the gel drop by drop 1.00g of hydrofluoric acid, stirred evenly, transferred to a 30ml polytetrafluoroethylene-lined stainless steel hydrothermal kettle and crystallized in an oven at 175°C for 7 days. After the crystallization was completed, the product was taken out and washed with deionized water until neutral. Transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com