A kind of method for preparing camphor by continuous dehydrogenation of isoborneol

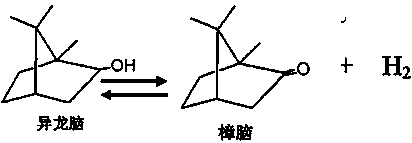

A technology for isoborneol and dehydrogenation, which is applied in the field of continuous dehydrogenation of isoborneol to prepare camphor, can solve the problems of unreasonable utilization of product hydrogen, unreasonable reactor design, short catalyst life, etc., and it is difficult to achieve local overheating phenomenon. , Improve the one-way conversion rate, the effect of not easy to deactivate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

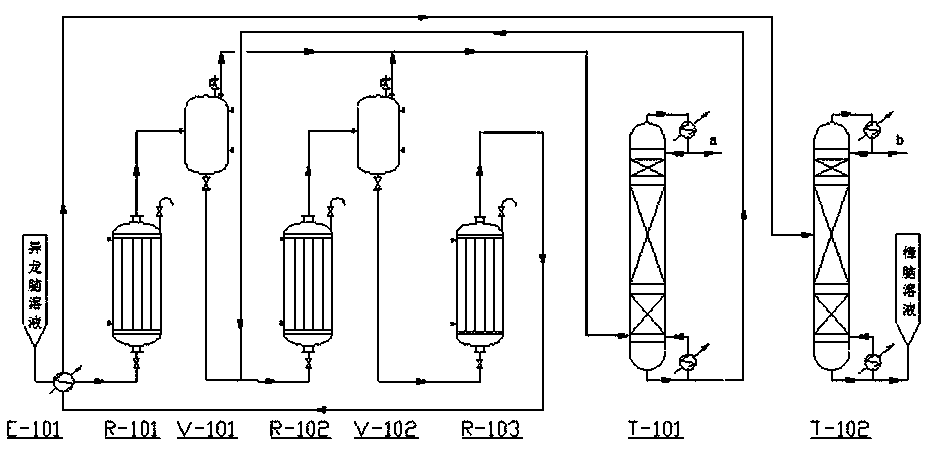

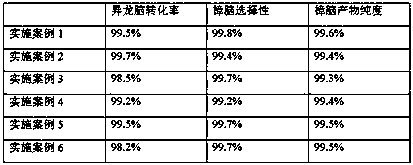

[0053] In this implementation case, at first the isoborneol solution is a solution with a mass fraction of 30% formed after the isoborneol is dissolved in p-xylene, and is first exchanged through the discharge of the heat exchanger E-101 and the reactor R-103 Heat, after reaching the preheating temperature of 220°C, enter the series reactor from the lower part of the reactor R-101 for dehydrogenation reaction: the reactor is a tubular fixed bed reactor, and the catalyst is packed in the tube side in the form of molding, The heat transfer medium heat transfer oil is installed on the shell side; the dehydrogenation catalyst is a Cu-Zn two-component dehydrogenation catalyst DH021 developed by the Nanjing Chemical Industry Co., Ltd. Research Institute; the air for the isoborneol dehydrogenation reaction Speed WHSV is 0.8h -1 , the number of reactors connected in series is 3, the reaction bed temperature is 220°C, 240°C, 260°C, the reaction pressure is 0.8 MPa, 0.9 MPa, 1.2 MPa, ...

Embodiment 2

[0056] The difference from Example 1 is that the space velocity WHSV of the isoborneol dehydrogenation reaction described in this example is 0.5h -1 .

Embodiment 3

[0058] The difference from Example 1 is that the solvent of isoborneol in this example is p-cymene.

[0059] Implementation 4

[0060] The difference from Example 1 is that the bed temperatures of the series reactors described in this example are 200° C., 220° C., and 240° C., and the reaction pressures are 0.5 MPa, 0.7 MPa, and 1 MPa sequentially.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com