Composite anion-exchange membrane and preparation method thereof

A composite anion and exchange membrane technology, applied in the coating and other directions, can solve the problems of complex composite membrane forming process, difficulty in scaling up, etc., and achieve the effects of easy mass production, improved stability, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

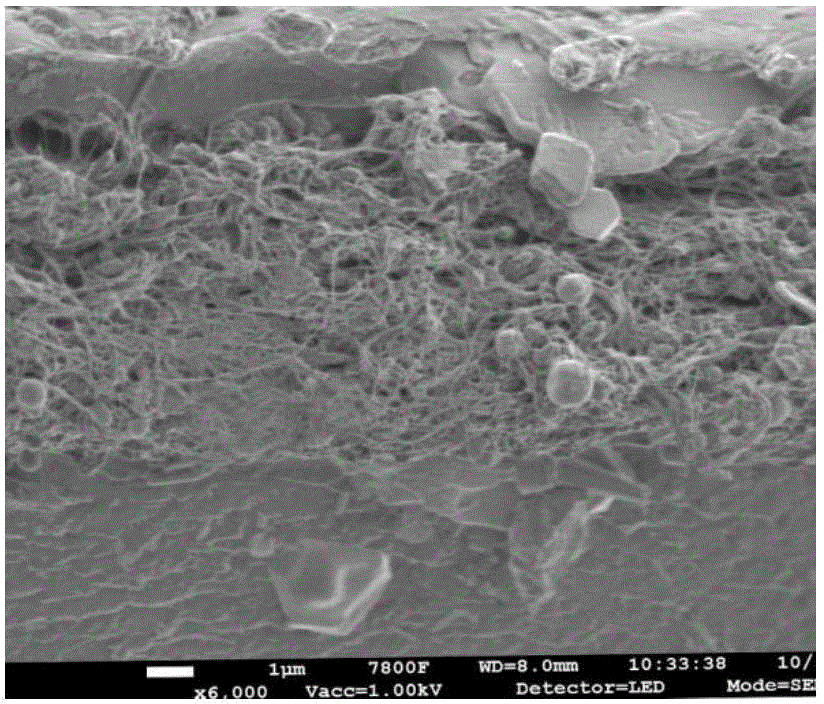

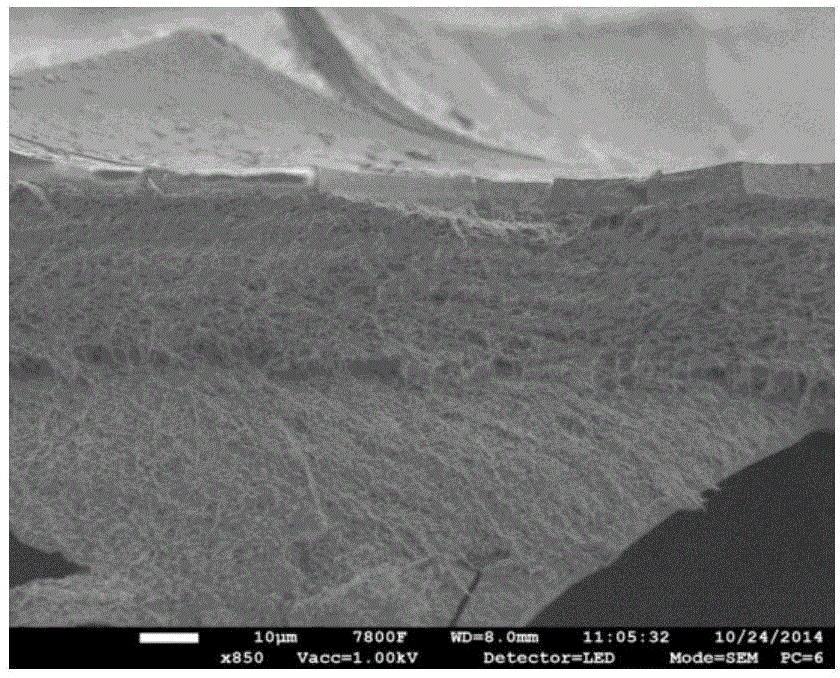

[0030] 1,2-dimethylimidazolium salt-type polyaryletherketone is prepared by traditional homogeneous solution reaction method, each mole of repeating unit contains about 1.7 moles of imidazolium salt functional groups, and a mixed solution with a solid content of 5wt% is prepared. The solvent used for NMP. Add ethanol according to the mass ratio of NMP:ethanol=1:5, add TEOS according to the mass ratio of polymer resin: TEOS=1:0.15, add surfactant according to the mass ratio of polymer resin: Tritinx-100=1:0.05, Stir evenly to obtain a spray solution. Expanded polytetrafluoroethylene with a pore size of 0.22 μm and a thickness of 20 μm was used as the base membrane, fixed with a plastic frame, and placed on a vacuum heating table. Set the temperature of the hot stage to 150°C, and keep the vacuum pump on. Use a spray gun with a diameter of 0.5mm to evenly spray the spray solution on the surface of the expanded polytetrafluoroethylene, and repeat the spraying to the surface of ...

Embodiment 2

[0032] The quaternary ammonium salt type polyaryletherketone is prepared by the traditional homogeneous solution reaction method, and each mole of repeating units contains about 1.7 moles of quaternary ammonium salt functional groups, and a mixed solution with a solid content of 5wt% is prepared, and the selected solvent is NMP and DMSO. The mixture, the ratio is 1:0.5. Add ethanol according to the mass ratio of mixed liquid: ethanol = 1:5, add TEOS according to the mass ratio of polymer resin: TEOS = 1:0.25, add surfactant at the mass ratio of Tritinx-100 = 1:0.10, stir evenly to get spray solution. Expanded polytetrafluoroethylene with a pore size of 0.45 μm and a thickness of 20 μm was used as the base membrane, fixed with a plastic frame, and placed on a vacuum heating table. Set the temperature of the hot stage to 180°C, and keep the vacuum pump on. Use a spray gun with a diameter of 0.5mm to evenly spray the spray solution on the surface of the expanded polytetrafluoro...

Embodiment 3

[0034] It is prepared by reacting 2-methylimidazole and 6-bromobutane under the catalysis of NaH at 0-6°C, and passing through the column to obtain pure N1-butyl-2-methylimidazole. N1-butyl-2-methylimidazolium salt type polystyrene was prepared by traditional homogeneous solution reaction method, and each mole of repeating units contained about 0.6 moles of imidazolium salt functional groups, and a mixed solution with a solid content of 5wt% was prepared. The solvent of choice is DMAc. Add ethanol according to the volume ratio of DMAc:ethanol=1:5, add TEOS according to the mass ratio of polymer resin:TEOS=100:15, add surfactant at the mass ratio of Tritinx-100=1:0.10, and stir evenly to obtain a spray solution . Expanded polytetrafluoroethylene with a pore size of 0.22 μm and a thickness of 20 μm was used as the base membrane, fixed with a plastic frame, and placed on a vacuum heating table. Set the temperature of the hot stage to 150°C, and keep the vacuum pump on. Use a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com