Production method of Sacha inchi polypeptide

A manufacturing method and a technology for printing Qiguo, applied in the field of vegetable protein processing, can solve problems such as short introduction time, and achieve the effects of good flavor, white color and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

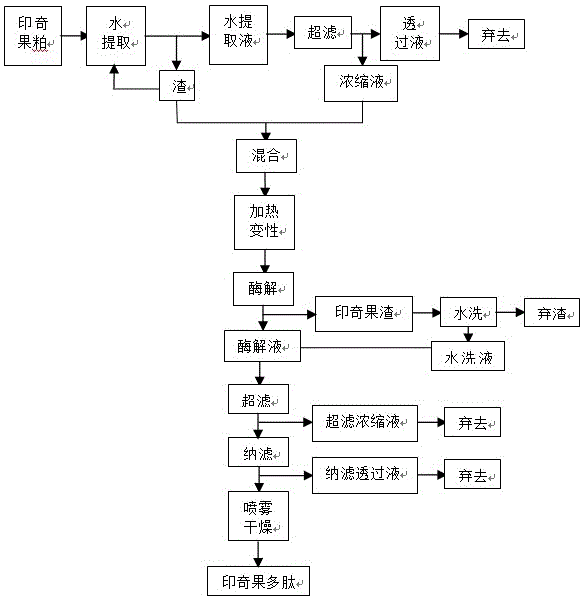

Image

Examples

Embodiment 1

[0035] The following is based on figure 1 As can be seen, a kind of manufacture method of Indian chi fruit polypeptide, its steps are:

[0036] (1) Crushing and sifting: take the Indian kiwi meal, pulverize it with a stainless steel pulverizer and sieve it through an 80-mesh standard sieve to obtain the Indian kiwi meal powder for later use;

[0037] ⑵Water extraction Take 500g of indica meal powder, add water 15 times its mass, stir at 100rpm for 0.5 hours, heat the mixture to 45°C and keep it at 45°C, continue to stir for 2.0 or 2.3 or 2.5 hours, dissolve Extract the water-soluble components, centrifuge with a decanter centrifuge to obtain the first water extract and the primary slag of Indian kiwi; add water 5 times its mass to the primary slag of Indian kiwi, stir for 1.0 or 1.3 or 1.5 hours, and use After being centrifuged in a decanter centrifuge, the second water extract and the second slag of Inchi fruit are obtained, and the first water extract and the second water ...

Embodiment 2

[0044] A kind of manufacture method of Indian chi fruit polypeptide, its steps are:

[0045] (1) Grinding and sifting to take the Indian kiwi meal, crushing it with a stainless steel grinder and sieving it through a 120-mesh standard sieve to obtain the Indian kiwi meal powder for later use;

[0046] ⑵Water extraction Take 500g of indica meal powder, add water 10 times its mass, stir at 120rpm for 1 hour, heat the mixture to 35°C and keep it at 35°C, continue to stir for 3.0 or 3.2 or 3.5 hours, dissolve Extract the water-soluble components, and centrifuge them with a decanter centrifuge to obtain the first water extract and the primary slag of Indian kiwi; add 10 times the mass of water to the primary slag of Indian kiwi, heat the mixture to 35°C and maintain it at 35°C ℃, continue to stir for 1.5 or 1.8 to 2.0 hours, centrifuge with a decanter centrifuge to obtain the second water extract and the second slag of Inchi fruit, combine the first water extract and the second wate...

Embodiment 3

[0053] A kind of manufacture method of Indian chi fruit polypeptide, its steps are:

[0054] (1) Grinding and sifting to take the Indian kiwi meal, crushing it with a stainless steel grinder and sieving it through a 120-mesh standard sieve to obtain the Indian kiwi meal powder for later use;

[0055] ⑵Water extraction Take 500g of indica meal powder, add water 10 times its mass, stir at 110rpm for 0.5 hours, heat the mixture to 65°C and keep it at 65°C, continue to stir for 1.5 or 1.7 or 2.0 hours, dissolve Extract the water-soluble components and centrifuge them in a decanter centrifuge to obtain the first water extract and the primary slag of Indian kiwi; add water 10 times its mass to the primary slag of Indian kiwi, heat the mixture to 65°C and maintain Stir at 65°C for 0.5 or 0.8 or 1.0 hours at a speed of 80rpm, centrifuge with a decanter centrifuge to obtain the second water extract and the second slag of Inchi fruit, combine the first water extract and the second water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com