Preparation method and application of quaternization modified amino silicon oil softener

A technology of quaternized ammonium modification and amino silicone oil, which is applied in the direction of improved hand-feeling fibers, textiles and papermaking, fiber treatment, etc. It can solve the complex preparation process, affect fabric overdyeing and color correction, and affect the whiteness of fabric hydrophilicity It is not ideal enough to achieve the effect of simple preparation of raw materials, high marketing value and economic benefits, and little influence on whiteness and hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

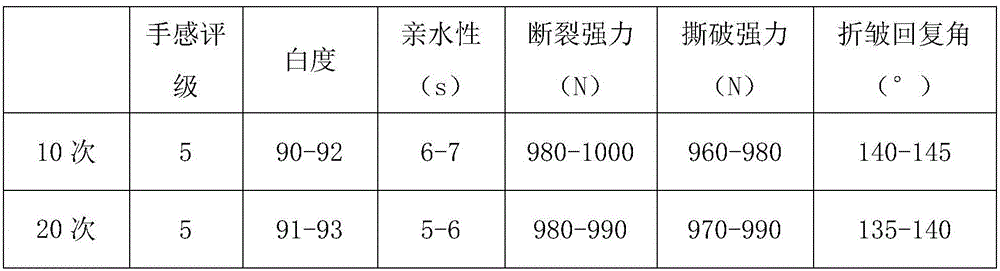

Examples

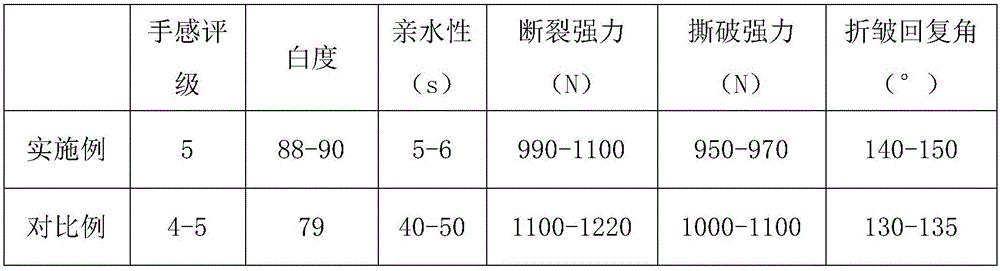

Embodiment 1

[0036] A preparation method of quaternized modified amino silicone oil softener, comprising the following steps:

[0037] The first step: Add epichlorohydrin to the container, stir and heat up to 55°C, then add trifluoroacetic acid dropwise, keep the reaction temperature at 60±2°C, stir and seal the reaction for 10 hours, the reaction solution is divided into two layers, and the upper layer is taken Transparent solution, the amount of trifluoroacetic acid added dropwise is 2% of the quality of epichlorohydrin;

[0038] Step 2: Dissolve amino silicone oil with an ammonia value of 0.6 in propyl acetate solvent, the mass ratio of amino silicone oil to propyl acetate is 1:1.2, add dropwise to the upper transparent solution prepared in the first step, stir and heat up to 70 ℃, after reacting for 4 hours, the quaternized modified amino silicone oil softener was prepared, and the dropping quality of the upper transparent solution prepared in the first step was 10% of the mass of amin...

Embodiment 2

[0040] A preparation method of quaternized modified amino silicone oil softener, comprising the following steps:

[0041] The first step: Add epichlorohydrin to the container, stir and heat up to 65°C, then add trifluoroacetic acid dropwise, keep the reaction temperature at 60±2°C, stir and seal the reaction for 12 hours, the reaction solution is divided into two layers, and the upper layer is taken Transparent solution, the amount of trifluoroacetic acid added dropwise is 3% of the quality of epichlorohydrin;

[0042] Step 2: Dissolve amino silicone oil with an ammonia value of 0.6 in propyl acetate solvent, the mass ratio of amino silicone oil to propyl acetate is 1:1.5, add dropwise to the upper transparent solution prepared in the first step, stir and heat up to 80 ℃, after reacting for 6 hours, the quaternized modified amino silicone oil softener was prepared, and the dropping quality of the upper transparent solution prepared in the first step was 15% of the mass of the ...

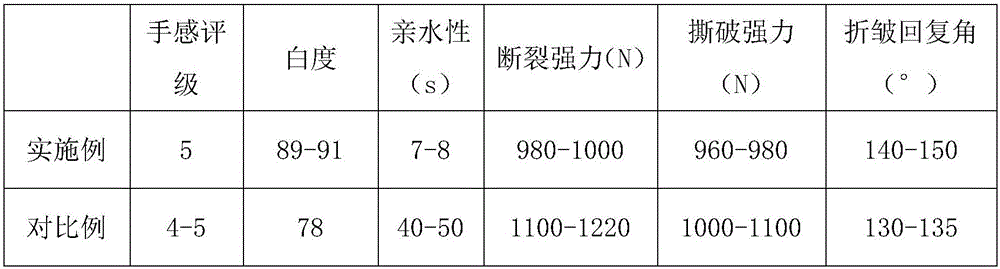

Embodiment 3

[0044] A preparation method of quaternized modified amino silicone oil softener, comprising the following steps:

[0045] Step 1: Add epichlorohydrin to the container, stir and heat up to 55°C, then add trifluoroacetic acid drop by drop, keep the reaction temperature at 60±2°C, stir and seal the reaction for 12 hours, the reaction solution is divided into two layers, and the upper layer is taken Transparent solution, the amount of trifluoroacetic acid added dropwise is 2% of the quality of epichlorohydrin;

[0046] The second step: dissolve amino silicone oil with an ammonia value of 0.6 in propyl acetate solvent, the mass ratio of amino silicone oil to propyl acetate is 1:1.5, add dropwise to the upper transparent solution prepared in the first step, stir and heat up to 70 ℃, after reacting for 6 hours, the quaternized modified amino silicone oil softener was prepared, and the dropping quality of the upper transparent solution prepared in the first step was 10% of the mass of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com