Method for preparing biodegradable polymer self-expansion type intravascular stent based on 3D printing technology

A technology for degrading polymers and vascular stents, applied in the field of biodegradable polymer self-expanding vascular stents based on 3D printing technology. The effect of improving long-term patency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

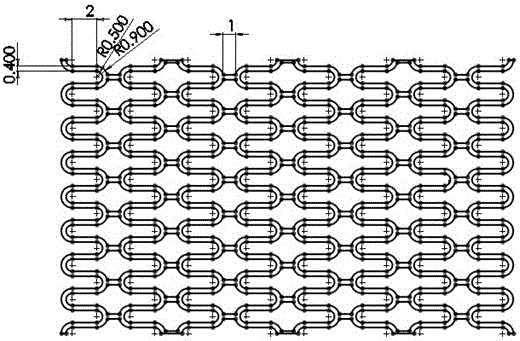

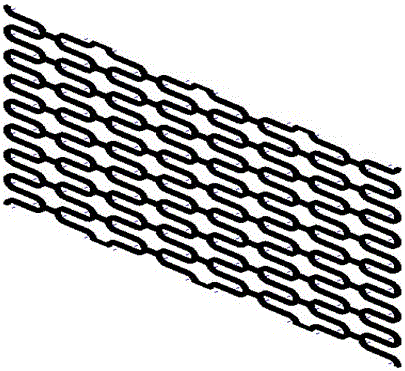

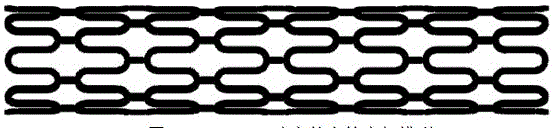

Image

Examples

Embodiment 1

[0031] (1) Synthesis of biodegradable polylactic acid-based shape memory polyurethane

[0032] With a molar ratio of 7:3 D,L - Lactide ( D,L -LA) with e- Caprolactone ( e- CL) as raw material, through ring-opening polymerization

[0033] Preparation of random copolymer PCLA, PCLA and hexamethylene diisocyanate (HDI) and flexible oligomer polytetrahydrofuran (PTMEG) chain extension to prepare biodegradable polylactic acid-based shape memory polyurethanes (PCLAUs), in which HDI and PCLA The mol ratio is 1.2:1, and the consumption of PTMEG is 10% of system gross mass;

[0034] (2) Biodegradable polylactic acid-based shape memory polyurethanes (PCLAUs) / Fe 3 o 4 Synthesis of Nanocomposites

[0035] The PCLAUs obtained in step (1) and the surface-modified magnetic Fe 3 o 4 Composite nanoparticles to prepare PCLAUs / Fe 3 o 4 nanocomposites; among them, the magnetic Fe 3 o 4 Nanoparticles are surface treated with oleic acid. In the composite system, the magnetic Fe 3 o 4 ...

Embodiment 2

[0047] (1) Synthesis of biodegradable polylactic acid-based shape memory polyurethane

[0048] With a molar ratio of 8:2 D,L - Lactide ( D,L -LA) with e- Caprolactone ( e- CL) as raw material, through ring-opening polymerization

[0049] Preparation of random copolymer PCLA, PCLA and hexamethylene diisocyanate (HDI) and flexible oligomer polytetrahydrofuran (PTMEG) chain extension to prepare biodegradable polylactic acid-based shape memory polyurethanes (PCLAUs), in which HDI and PCLA The mol ratio is 1.04:1, and the consumption of PTMEG is 10% of system gross mass;

[0050] (2) Biodegradable polylactic acid-based shape memory polyurethanes (PCLAUs) / Fe 3 o 4 Synthesis of Nanocomposites

[0051] The PCLAUs obtained in step (1) and the surface-modified magnetic Fe 3 o 4 Composite nanoparticles to prepare PCLAUs / Fe 3 o 4 nanocomposites; among them, the magnetic Fe 3 o 4 Nanoparticles are surface treated with oleic acid. In the composite system, the magnetic Fe 3 o ...

Embodiment 3

[0065] (1) Synthesis of biodegradable polylactic acid-based shape memory polyurethane

[0066] With a molar ratio of 9:1 D,L - Lactide ( D,L -LA) with e- Caprolactone ( e- CL) as raw material, through ring-opening polymerization

[0067] Preparation of random copolymer PCLA, PCLA and hexamethylene diisocyanate (HDI) and flexible oligomer polytetrahydrofuran (PTMEG) chain extension to prepare biodegradable polylactic acid-based shape memory polyurethanes (PCLAUs), in which HDI and PCLA The mol ratio is 1.10:1, and the consumption of PTMEG is 10% of system gross mass;

[0068] (2) Biodegradable polylactic acid-based shape memory polyurethanes (PCLAUs) / Fe 3 o 4 Synthesis of Nanocomposites

[0069] The PCLAUs obtained in step (1) and the surface-modified magnetic Fe 3 o 4 Composite nanoparticles to prepare PCLAUs / Fe 3 o 4 nanocomposites; among them, the magnetic Fe 3 o 4 Nanoparticles are surface treated with oleic acid. In the composite system, the magnetic Fe 3 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com