Low-template-consumption punicalin imprinting method based on dual-crowding effect

A pomegranate grove and crowding technology, which is applied in the field of imprinting of pomegranate groves with low template consumption based on the double crowding effect, can solve the problems of high cost of imprinting, consumption of large pomegranate groves, and high price of pomegranate groves, achieving low cost of imprinting, Excellent retention performance, the effect of excellent retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Two crowding reagents, polyethylene glycol with an average molecular mass of 6,000 and polystyrene with an average molecular mass of 350,000 were dissolved in tetrahydrofuran solution, and the concentration of polyethylene glycol in the obtained solution was 19.4 mg / mL, polystyrene The concentration is 40mg / mL, and the mass percentage of 0.035% pomegranate is dissolved in the tetrahydrofuran solution containing two crowding reagents with a mass fraction of 68.35%;

[0020] Then add acrylamide with a mass fraction of 2.48%, ethylene glycol dimethacrylate with a mass fraction of 20.80%, toluene with a mass fraction of 6.92%, and azobisisobutyronitrile with a mass fraction of 1.40%, and ultrasonically for 10 minutes. The solution was clarified, transferred to a stainless steel column (100×4.6mm) with a length of 100mm and a diameter of 4.6mm, sealed both ends of the stainless steel column tube, and thermally initiated the reaction in a constant temperature water bath at a t...

Embodiment 2

[0024] Preparation of Blank Control Column by In-Situ Polymerization

[0025] The blank control column was prepared by in-situ polymerization: two crowding reagents polyethylene glycol and polystyrene were dissolved in tetrahydrofuran solution respectively. mL;

[0026] Acrylamide with a mass percentage of 2.49%, ethylene glycol dimethacrylate with a mass fraction of 20.81%, toluene with a mass fraction of 6.93%, and azobisisobutyronitrile with a mass fraction of 1.40% were ultrasonically dissolved for 10 minutes. After the solution is clarified, transfer it to a stainless steel column (100×4.6mm), seal both ends of the stainless steel column tube, and thermally initiate the reaction in a constant temperature water bath at a temperature of 55°C for 24 hours;

[0027] Residual porogen and functional monomer removal: Take out the synthesized stainless steel column, put it on the column head, connect it to a high-pressure infusion pump, and use 150mL tetrahydrofuran, 100mL metha...

Embodiment 3

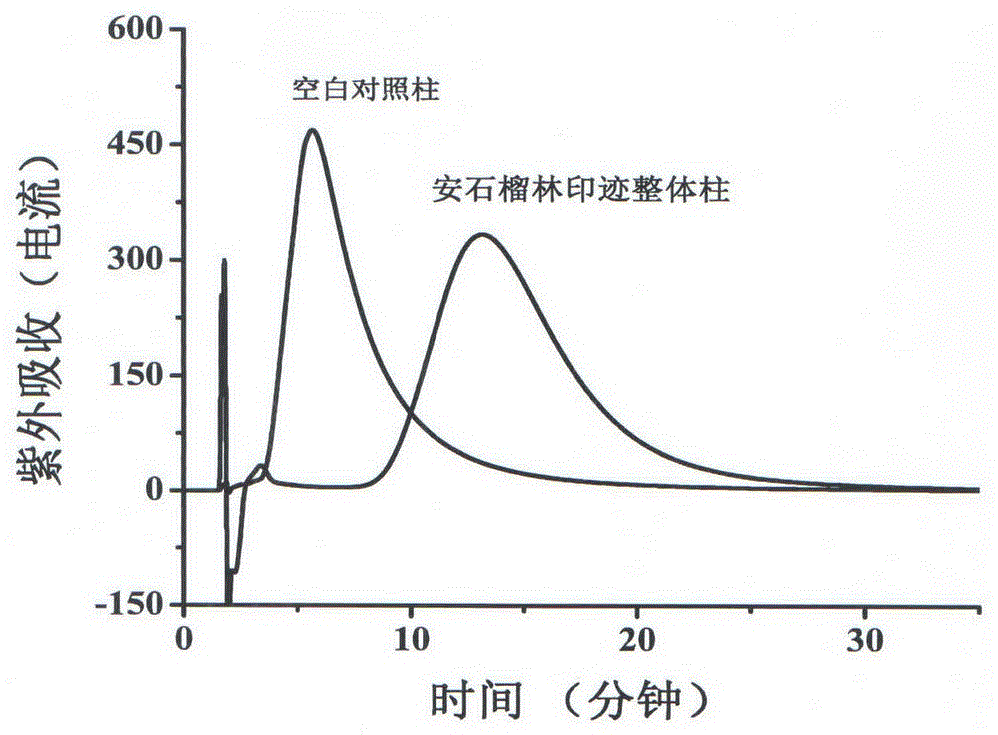

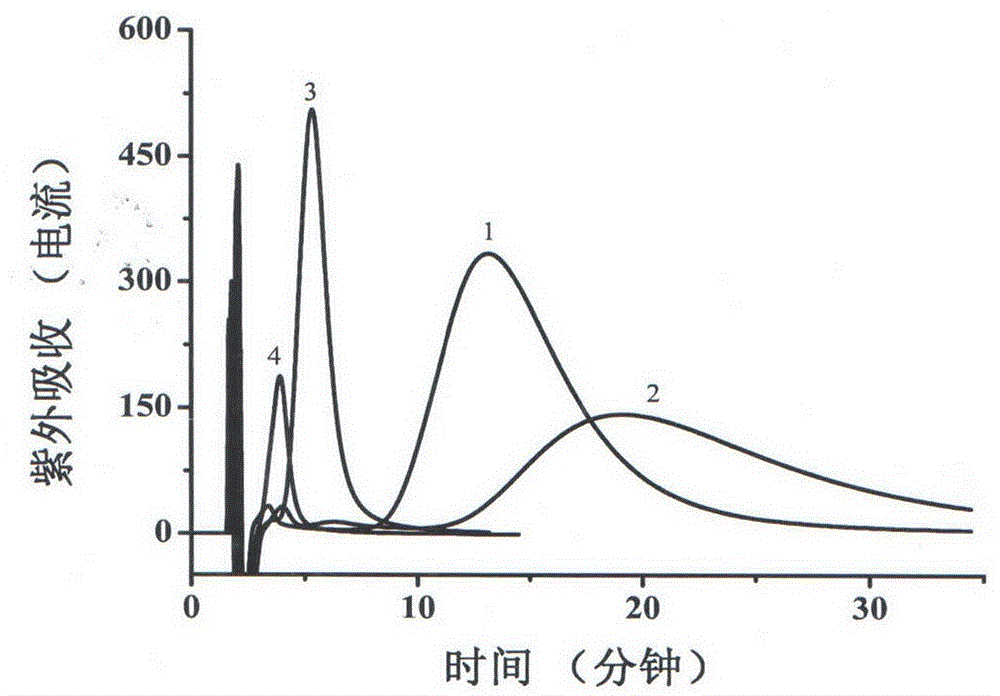

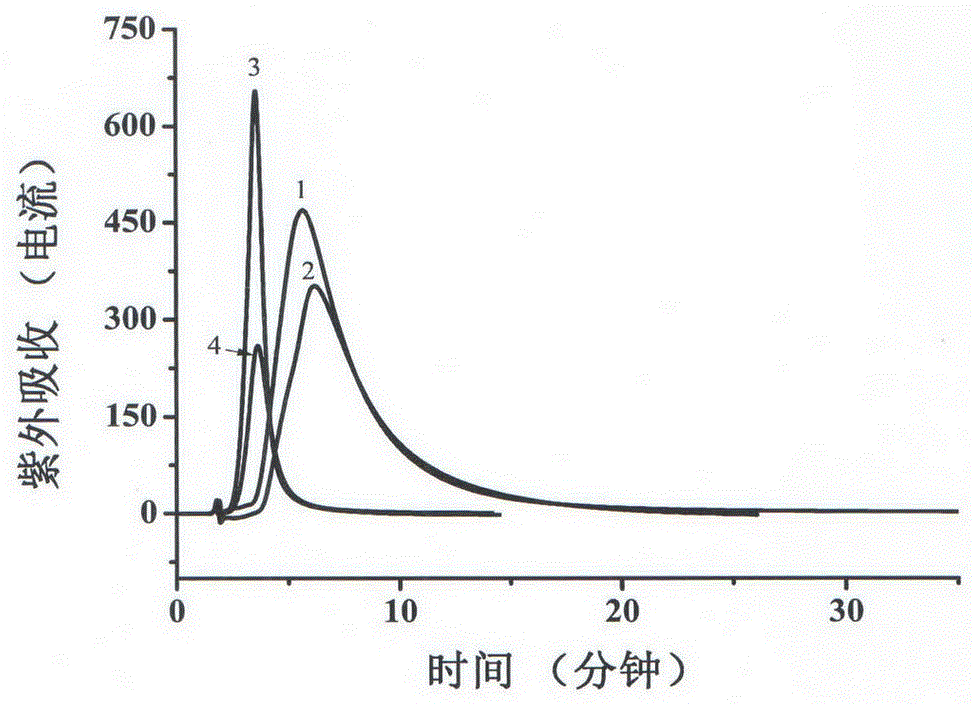

[0030] Evaluation of Selective Performance of Pomegranate Imprinted Monolithic Column and Its Blank Control Column

[0031] Selective performance evaluation of pomegranate imprinted monolithic column: set the UV absorption wavelength to 258nm, flow rate to 1.0mL / min, column temperature to 35°C, use acetonitrile-acetic acid buffer salt (pH3.6, 200mmol / L) (92:8, v / v) Flush the imprinted monolithic column of pomegranate to the baseline level, inject samples of pomegranate, punicalagin, ellagic acid and tannil extract respectively, and obtain the chromatograms of various substances on the monolithic column. Such as figure 2 It was shown that the imprinted monolithic column of punicalagin has a strong retention of punicalagin and punicalagin, and can effectively separate the two from ellagic acid and punicalagin. It shows that the present invention has the function of simultaneously separating punicalagin and punicalagin;

[0032] Selective performance evaluation of the blank c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com