Ruthenium precursor for preparing ruthenium carbon catalyst and preparation method of catalyst

A technology of ruthenium carbon catalyst and ruthenium precursor, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Surface area reduction and other issues, to achieve the effect of simple control, low cost, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

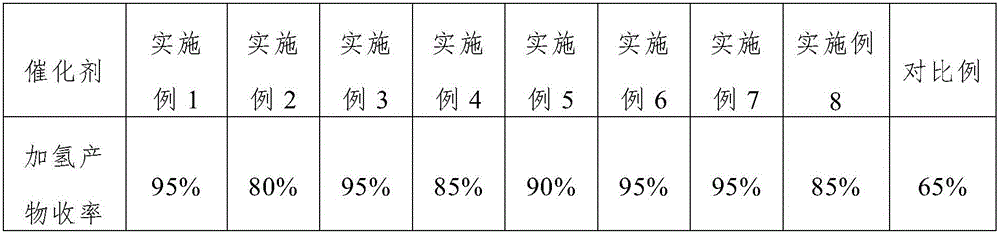

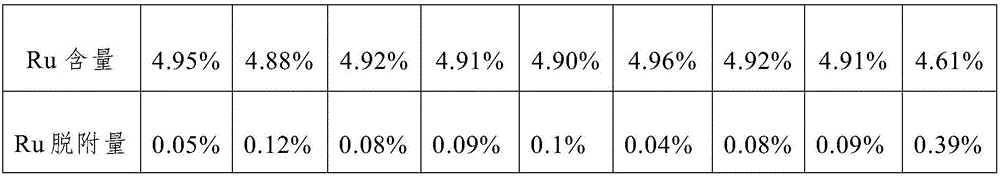

Examples

Embodiment 1

[0025] The ruthenium precursor of this embodiment is prepared according to the following method:

[0026] Step 1, sodium formate is added in the ruthenium trichloride solution that concentration is 0.01g / mL, stirs to obtain mixed solution; The quality of described sodium formate is 5 times of the ruthenium mass in ruthenium trichloride;

[0027] Step 2. Heat the mixed solution described in step 1 to 70°C, then add polyvinylpyrrolidone (PVP-K30) to the heated mixed solution, and stir until the polyvinylpyrrolidone is completely dissolved to obtain a dark green solution that is used for The ruthenium precursor of the ruthenium carbon catalyst is prepared; the quality of the polyvinylpyrrolidone is twice that of the ruthenium in ruthenium trichloride.

[0028] The method for preparing ruthenium carbon catalyst (ruthenium loading is 5%) using the ruthenium precursor of the present embodiment is:

[0029] Step 1. Place activated carbon (the quality of activated carbon is 19 times ...

Embodiment 2

[0033] The ruthenium precursor of this embodiment is prepared according to the following method:

[0034] Step 1, sodium formate is added in the ruthenium nitrate solution that concentration is 0.1g / mL, stirs to obtain mixed solution; The quality of described sodium formate is 2 times of the ruthenium quality in ruthenium nitrate;

[0035] Step 2. Heat the mixed solution described in step 1 to 90°C, then add polyvinylpyrrolidone (PVP-K15) to the heated mixed solution, and stir until the polyvinylpyrrolidone is completely dissolved to obtain a dark green solution that is used for The ruthenium precursor of the ruthenium carbon catalyst is prepared; the quality of the polyvinylpyrrolidone is twice that of the ruthenium in the ruthenium nitrate.

[0036] The method for preparing ruthenium carbon catalyst (ruthenium loading is 5%) using the ruthenium precursor of the present embodiment is:

[0037] Step 1. Place activated carbon (the quality of activated carbon is 19 times the ma...

Embodiment 3

[0041] The ruthenium precursor of this embodiment is prepared according to the following method:

[0042] Step 1, sodium formate is added concentration is in the ruthenium acetate solution of 0.05g / mL, stirs to obtain mixed solution; The quality of described sodium formate is 5 times of ruthenium quality in ruthenium acetate;

[0043] Step 2. Heat the mixed solution described in step 1 to 80°C, then add polyvinylpyrrolidone (PVP-K25) to the heated mixed solution, and stir until the polyvinylpyrrolidone is completely dissolved to obtain a dark green solution that is used for The ruthenium precursor of the ruthenium carbon catalyst is prepared; the quality of the polyvinylpyrrolidone is 5 times that of the ruthenium in the ruthenium acetate.

[0044] The method for preparing ruthenium carbon catalyst (ruthenium loading is 5%) using the ruthenium precursor of the present embodiment is:

[0045] Step 1. Place activated carbon (the quality of activated carbon is 19 times the mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com