Methods for preparing wave absorbing catalyst and for degrading organic wastewater

A technology of organic wastewater and catalysts, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. It can solve the problems of inability to be reused many times, high cost of catalysts, low strength of activated carbon, etc., and achieve good microwave Absorption performance, good catalytic activity, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for microwave-assisted degradation of organic waste water comprises the following steps:

[0038] (1) The zero-valent iron catalyst loaded on carbon silicon tubes further includes the following steps:

[0039] (1-1) Pretreatment: Put the carbon silicon tube into a 5% nitric acid solution and ultrasonically for 30 minutes, take out the carbon silicon tube, wash it with deionized water and dry it.

[0040] (1-2) Put the pretreated carbon-silicon tube into a ferrous sulfate solution with a concentration of 0.2mol / L, take it out after 5 hours, and then use direct current for electrodeposition. Electrolyte: 200mL ferrous sulfate solution, pH=2~4; cathode: silicon carbide profile, anode: iron sheet; current 1A; electrodeposition time 10min. The zero-valent transition metal catalyst supported on the silicon carbide profile is obtained. For the convenience of storage, the prepared catalyst can be vacuum-dried at 45° C.

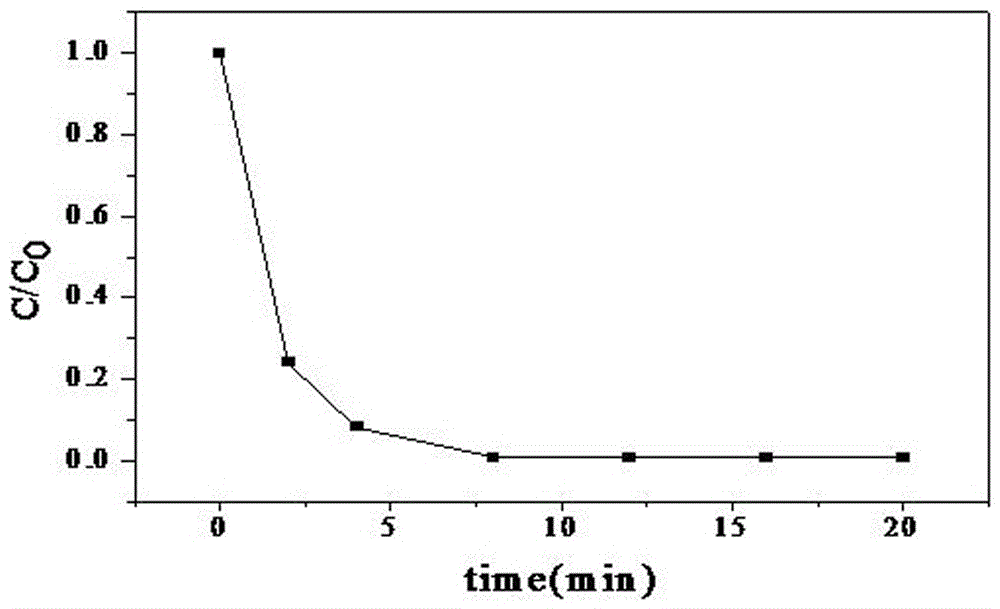

[0041] (2) Add 24g of catalyst to 100mL of n...

Embodiment 2

[0044] The method for microwave-assisted degradation of organic waste water comprises the following steps:

[0045] (1) The preparation of carbon silicon rod-supported zero-valent iron catalyst further includes the following steps:

[0046] (1-1) Pretreatment: put the carbon silicon rod into a 1% nitric acid solution and ultrasonically for 40 minutes, take out the carbon silicon rod, wash it with deionized water and dry it.

[0047] (1-2) Put the pretreated carbon-silicon tube into a ferrous sulfate solution with a concentration of 0.4mol / L, take it out after 5 hours, and then use direct current for electrodeposition. Electrolyte: 200mL ferrous sulfate solution, pH=2~4; cathode: silicon carbide profile, anode: iron sheet; current 1A; electrodeposition time 10min. The zero-valent transition metal catalyst supported on the silicon carbide profile is obtained. For the convenience of storage, the prepared catalyst can be vacuum-dried at 45° C.

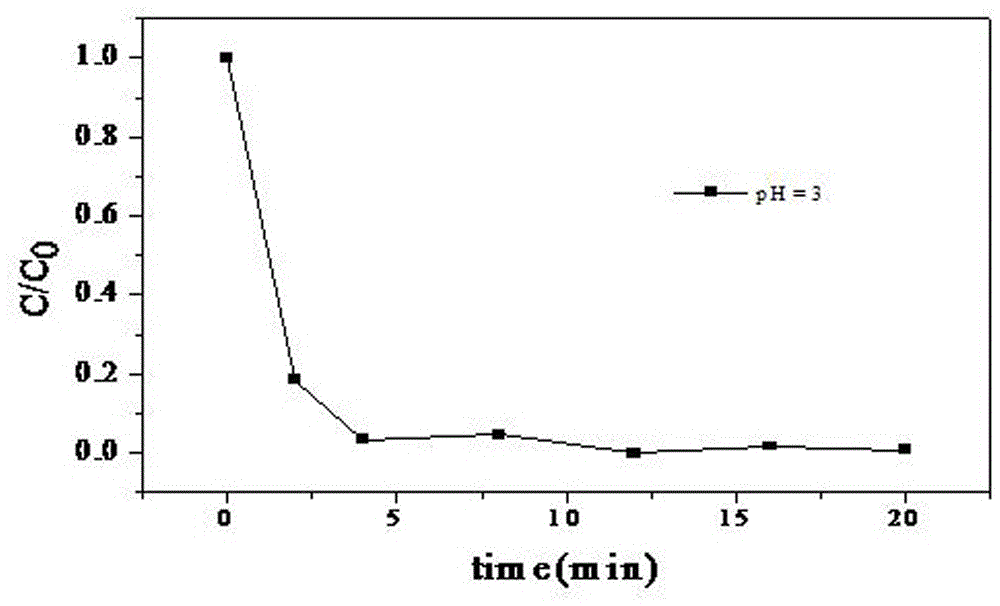

[0048] (2) Add 16g of catalyst to...

Embodiment 3

[0051] The method for microwave-assisted degradation of organic waste water comprises the following steps:

[0052] (1) The preparation of carbon silicon tube supported zero-valent iron catalyst further includes the following steps:

[0053] (1-1) Pretreatment: Put the carbon silicon tube into a 3% nitric acid solution and ultrasonically for 60 minutes, take out the carbon silicon tube, wash it with deionized water and dry it.

[0054] (1-2) Put the pretreated carbon-silicon tube into the ferrous sulfate solution with a concentration of 0.3mol / L, take it out after 5 hours, and then use direct current for electrodeposition. Electrolyte: 200mL ferrous sulfate solution, pH=2~4; cathode: silicon carbide profile, anode: iron sheet; current 1A; electrodeposition time 10min. The zero-valent transition metal catalyst supported on the silicon carbide profile is obtained. For the convenience of storage, the prepared catalyst can be vacuum-dried at 45° C.

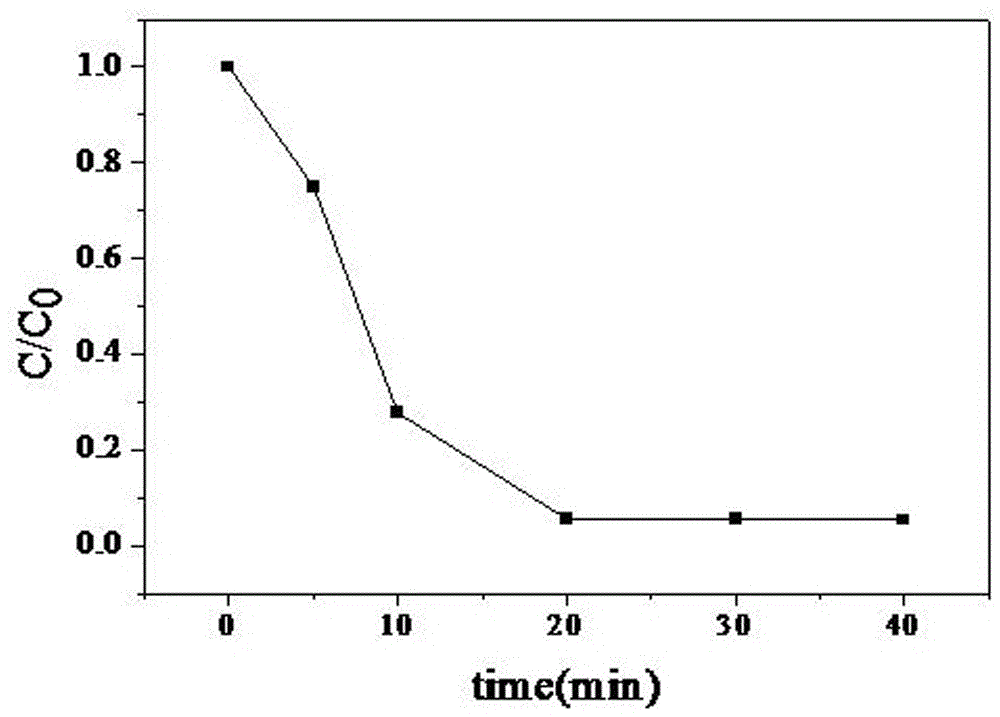

[0055] (2) Add 16g of cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com