Formic acid dehydrogenation catalysts in aqueous system, and application thereof

A catalyst, formic acid technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, hydrogen, etc., to achieve the effect of easy mass synthesis, high formic acid dehydrogenation activity, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

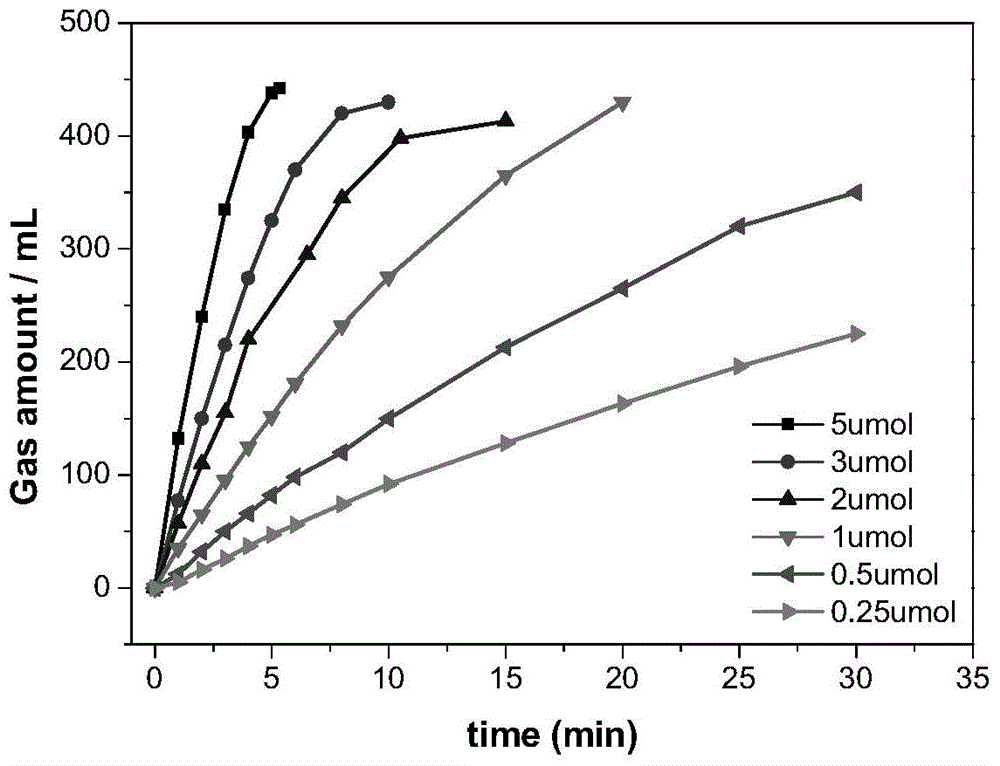

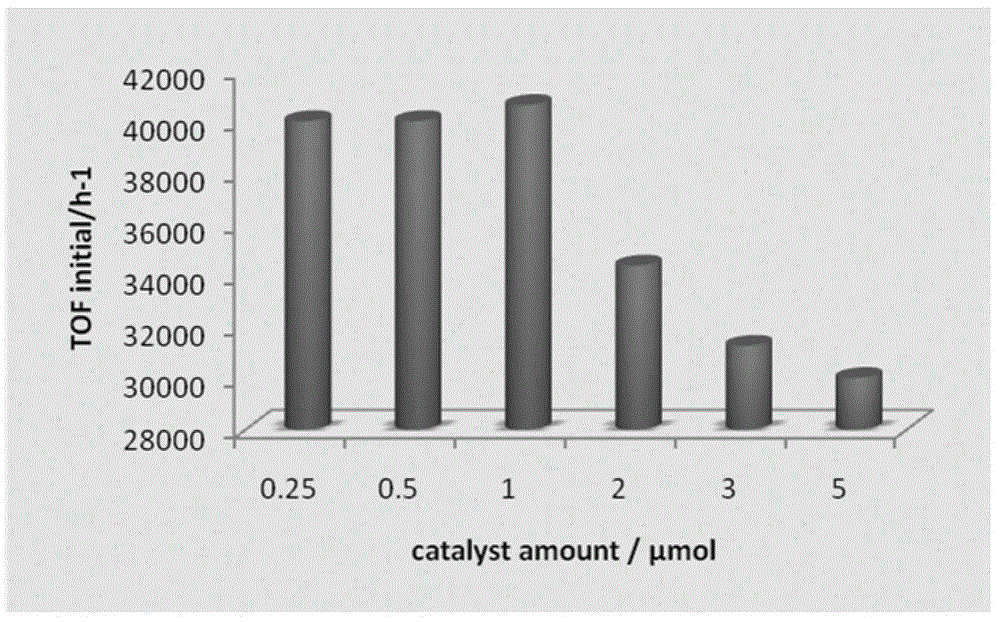

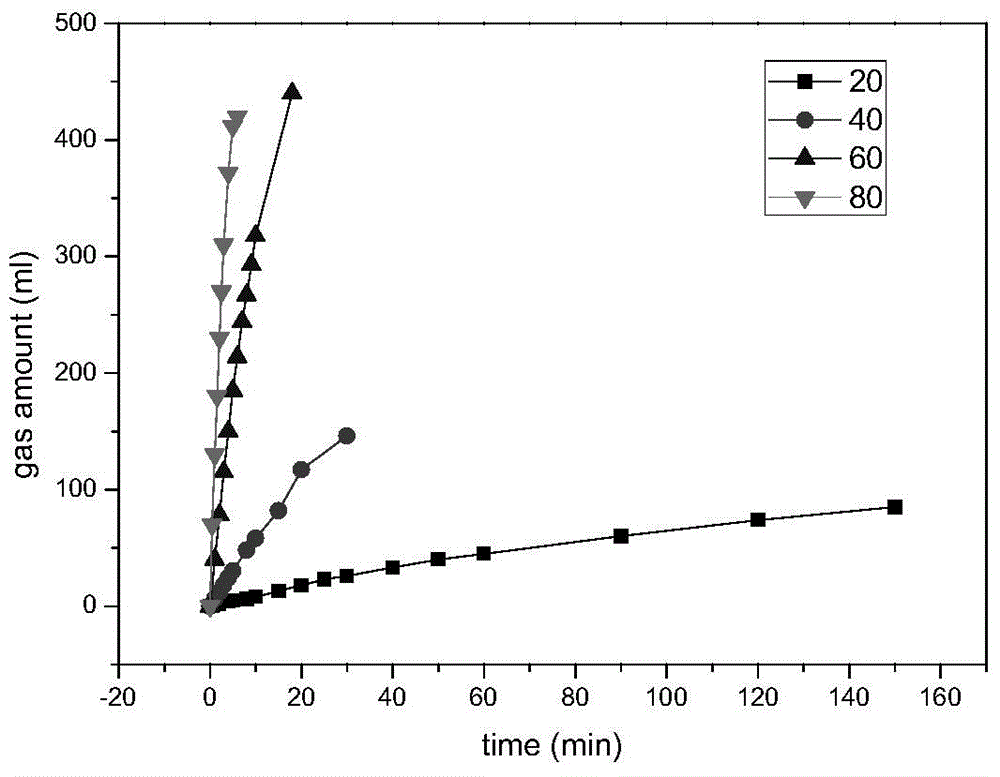

[0030] Weigh [Cp*IrCl 2 ] 2 (4.0mg, 5.0μmol) and L1 (6.8mg, 50μmol) were placed in a reagent bottle, and 10mL of degassed pure water was added to prepare an aqueous solution of the in-situ catalyst. Add a stirring magnet, water (8.62mL) and 1.0mL (0.5μmol) of the above prepared catalyst solution to a Schlenk reaction bottle (50mL), seal it with a rubber stopper, put it in a water bath at 60°C and stir for 10min Finally, unscrew the branch pipe to communicate with the atmosphere, then close it, connect the rubber tube to the inverted 500mL graduated cylinder filled with water in the water basin, inject formic acid (10mmol, 0.38mL) into the reaction bottle through the rubber stopper with a syringe, and start timing. Open the branch pipe piston and collect the gas by draining. Calculate the amount of gas collected per unit time, calculate TON and TOF, V(CO 2 )=Volume / 2 of drained water, the amount of formic acid decomposed M(CO 2 ) = V(CO 2 ) / 24, see Table 1 for specific dat...

Embodiment 2

[0032] Same as Example 1, except that ligand L2 was used instead of L1 for the reaction, and the results are shown in Table 1.

Embodiment 3

[0034] Same as Example 1, except that ligand L3 was used instead of L1 for the reaction, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com