Electrolysis system without cell shell

An electrolysis system and tank technology applied in water/sewage treatment, sterilization/microdynamic water/sewage treatment, water/sludge/sewage treatment, etc. Manage maintenance troubles and other issues to achieve the effect of flexible and diverse assembly methods, no heat loss, and convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

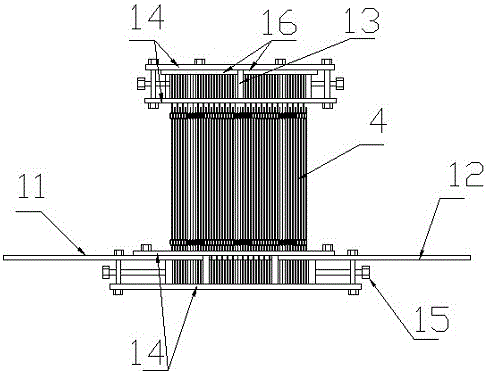

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

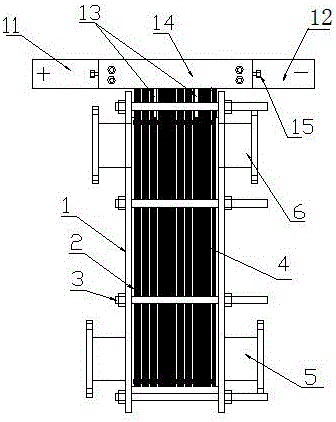

[0033] Such as figure 1 As shown, a tankless electrolysis system mainly includes a steel fastening plate 1, an end face insulating plate 2, a fastening screw 3, a pole plate 4 and a conductive device, and the pole plate 4 is arranged on at least two steel tight plates. Between the fastening plates 1 , the steel fastening plate 1 is provided with an end face insulation plate 2 near the pole plate 4 , and the steel fastening plates 1 are connected by fastening screws 3 .

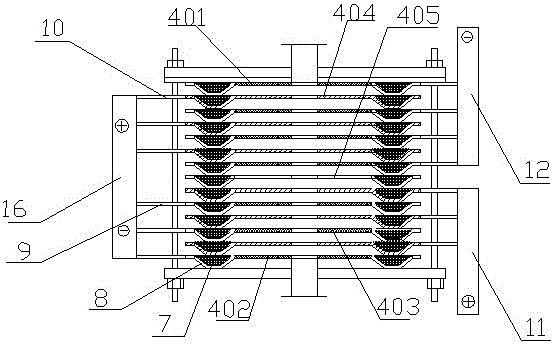

[0034] Such as figure 2As shown, the pole plate 4 mainly includes end face pole plates 401, 402, a cathode plate 403, an anode plate 404, and a single-sided coating plate 405. The periphery of the pole plate 4 is provided with sealing grooves 7, and the sealing grooves A seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com