Method for removing undigested matter in anaerobic digestive liquid and preparing organic liquid fertilizer base fluid

An anaerobic digestion and organic matter technology, which is applied in chemical instruments and methods, organic fertilizers, biological organic part treatment, etc. problem, to achieve the effect of reducing crude fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

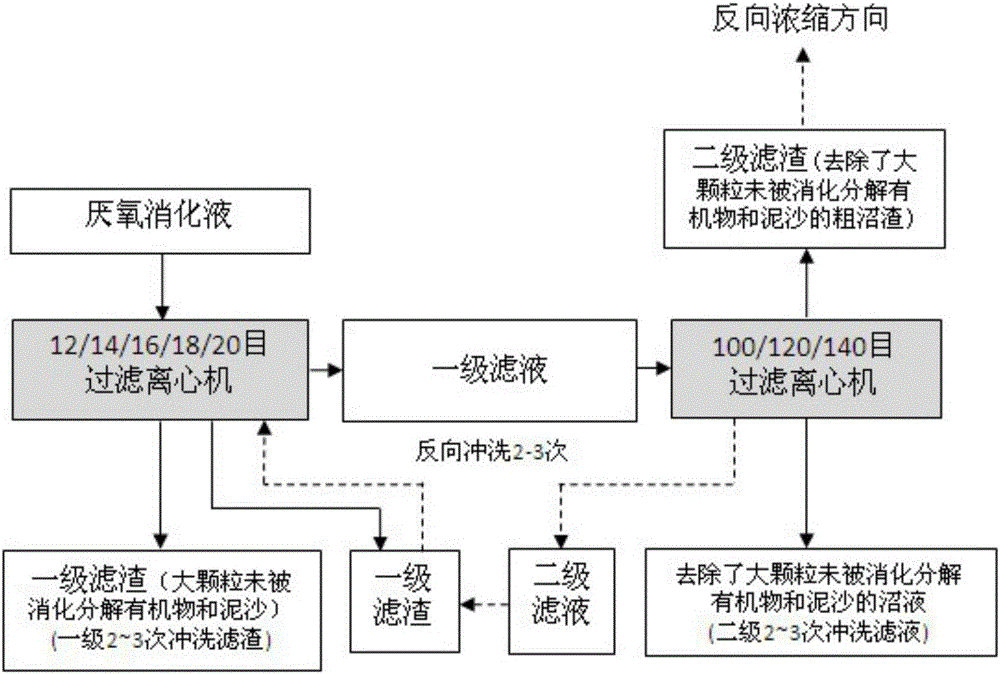

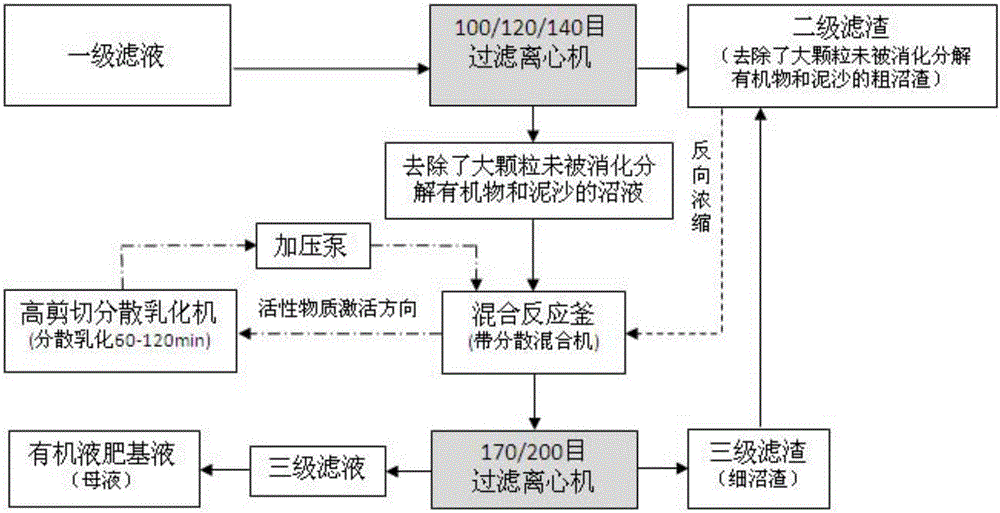

[0057] This example is used to illustrate the graded treatment of anaerobic digestion liquid and use it to remove large particles of undigested and decomposed organic matter and sediment (coarse biogas residue and biogas slurry obtained after removing large particles of undigested and decomposed organic matter and sediment) The method for preparing organic liquid fertilizer base liquid as raw material comprises the following steps:

[0058](1) Remove large particles of undigested and decomposed organic matter and sediment: the anaerobic digestion solution (solid content 8%) is pumped into the LX-950-12 mesh filter centrifuge through the pipeline for primary filtration and separation. Among them, the "first-level filter residue" (large particles of undigested and decomposed organic matter and sediment) enters the first-level large-particle undigested and decomposed organic matter and sediment storage tank, and the first-level filtrate enters the first-level filtrate storage tank...

Embodiment 2

[0061] This example is used to illustrate the graded treatment of anaerobic digestion liquid and use it to remove large particles of undigested and decomposed organic matter and sediment separation (coarse biogas residue and biogas slurry obtained after removing large particles of undigested and decomposed organic matter and sediment) The method for preparing organic liquid fertilizer base liquid as raw material comprises the following steps:

[0062] (1) Removal of large particles of undigested and decomposed organic matter and sediment: the anaerobic digestion solution (solid content 5%) is pumped through the pipeline into the LX-950-16 mesh filter centrifuge for primary filtration and separation. Among them, the "first-level filter residue" (large particles of undigested and decomposed organic matter and sediment) enters the first-level large-particle undigested and decomposed organic matter and sediment storage tank, and the first-level filtrate enters the first-level filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com