Method for processing smelting waste acid

A technology of polluted acid and raw materials, which is applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems that have not been implemented, and achieve efficiency improvement, simple operation, and low treatment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

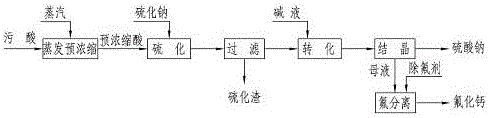

[0022] A method for treating smelting sewage acid, comprising the following steps in sequence:

[0023] (1) Evaporate and concentrate the dirty acid: the raw dirty acid first enters the multi-effect evaporation concentration device, controls the multi-effect evaporation temperature at 105°C-110°C, evaporates most of the water in the dirty acid, and increases the concentration of the dirty acid to 20% -35%; at this time, the arsenic ions and fluorine and chlorine in the dirty acid are not precipitated, and the secondary steam condensate does not contain fluorine and chlorine and can be returned for use.

[0024] (2) Vulcanization: Then use sodium sulfide to vulcanize, clarify, and filter the polluted acid treated in step (1) to remove arsenic and heavy metals; at this time, since the concentration of polluted acid is increased to 20%-35% The efficiency of direct sulfidation is significantly improved, and the arsenic content in the sulfide slag obtained by filtration is relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com