Novel ceramic tile adhesive and preparation method thereof

A tile adhesive, a new type of technology, applied in the field of building materials, can solve the problems of weak adhesion and easy falling off, and achieve the effect of strong adhesion, long service life and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

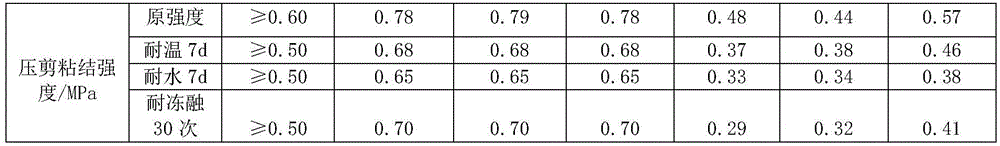

Examples

Embodiment 1

[0027] A new type of tile adhesive, which consists of: 35kg of cement, 25kg of heavy calcium carbonate with a particle size of 120μm, 20kg of building gypsum, 6kg of bentonite, 12.5kg of redispersible latex powder, 4.53kg of polypropylene fiber with a fiber length of 9mm, Calcium formate 4.53kg, hydroxyethyl cellulose ether 5.63kg, starch ether 3.64kg, water reducer 1.26kg, water-based acid alcohol resin defoamer 3.52kg and magnesium aluminum silicate thixotropic lubricant 1.52kg.

[0028] The bentonite is formed by mixing sodium-based bentonite and calcium-based bentonite according to a mass ratio of 4:3.

[0029] The preparation method of described novel ceramic tile adhesive is:

[0030] A. Put cement, heavy calcium carbonate, construction gypsum and bentonite into the mixer and stir for 18 minutes;

[0031] B. Add the redispersible latex powder to the mixture described in step A and stir for 3 minutes;

[0032] C. adding polypropylene fiber, hydroxyethyl cellulose ether ...

Embodiment 2

[0035] A new type of tile adhesive, which consists of: 20kg of cement, 30kg of heavy calcium carbonate with a particle size of 80μm, 15kg of building gypsum, 15kg of bentonite, 9.6kg of redispersible latex powder, 7.24kg of polypropylene fiber with a fiber length of 6mm, Calcium formate 2.12kg, hydroxypropyl cellulose ether 3.26kg, starch ether 2.31kg, water reducer 2.68kg, water-based acid alcohol resin defoamer 2.44kg and magnesium aluminum silicate thixotropic lubricant 2.72kg.

[0036] The bentonite is formed by mixing sodium-based bentonite and calcium-based bentonite according to a mass ratio of 5:2.

[0037] The preparation method of described novel ceramic tile adhesive is:

[0038] A. Put cement, heavy calcium carbonate, construction gypsum and bentonite into the mixer and stir for 15 minutes;

[0039] B. Add the redispersible latex powder into the mixture described in step A and stir for 5 minutes;

[0040] C. adding polypropylene fiber, hydroxypropyl cellulose eth...

Embodiment 3

[0043] A new type of tile adhesive, which consists of: 28kg of cement, 27kg of heavy calcium carbonate with a particle size of 100μm, 18kg of building gypsum, 12kg of bentonite, 11.6kg of redispersible latex powder, 5.85kg of polypropylene fiber with a fiber length of 8mm, Calcium formate 3.33kg, hydroxypropyl cellulose ether 4.45kg, starch ether 2.92kg, water reducer 1.98kg, water-based acid alcohol resin defoamer 2.96kg and magnesium aluminum silicate thixotropic lubricant 2.12kg.

[0044] The bentonite is formed by mixing sodium-based bentonite and calcium-based bentonite according to a mass ratio of 4:2.

[0045] The preparation method of described novel ceramic tile adhesive is:

[0046] A. Put cement, heavy calcium carbonate, construction gypsum and bentonite into the mixer and stir for 156 minutes;

[0047] B. Add the redispersible latex powder to the mixture described in step A and stir for 4 minutes;

[0048] C. adding polypropylene fiber, hydroxypropyl cellulose ethe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com