Preparation of algal polysaccharide and application of algal polysaccharide in cosmetics

A seaweed polysaccharide and seaweed technology, applied in the field of preparation and its application in cosmetics, can solve problems such as complicated procedures, achieve good water solubility, strong anti-oxidation, and delay aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

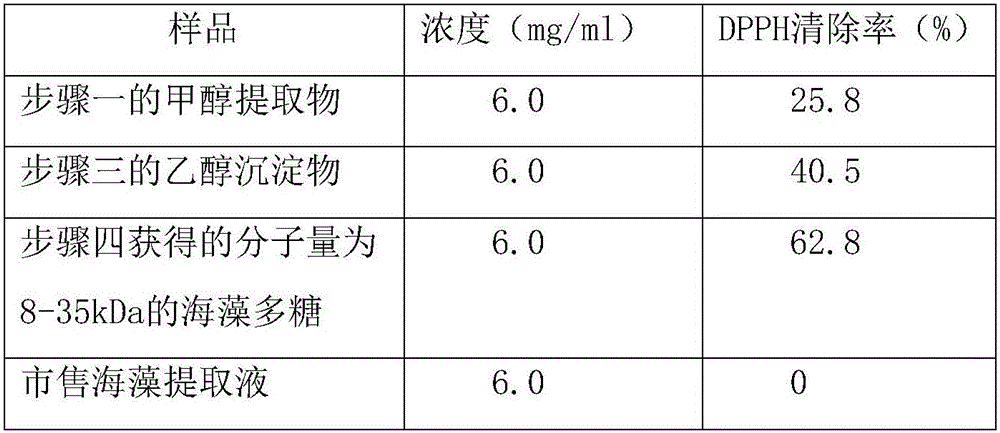

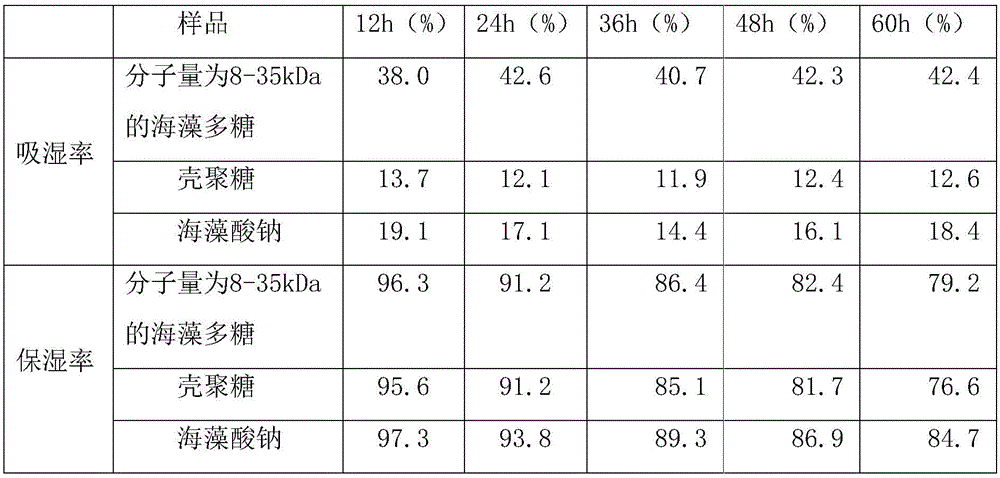

Embodiment 1

[0052] The present embodiment provides a kind of preparation method of seaweed polysaccharide, comprising the following steps:

[0053] Step 1: Remove impurities

[0054] According to the solid-to-liquid ratio g / mL (1:20), the dried and pulverized seaweed was refluxed with methanol to extract for 4 hours, filtered, and the filtrate recovered methanol;

[0055] Step 2: Extract

[0056] Extract the dried filter residue with 0.2M hydrochloric acid solution, the solid-liquid ratio of filter residue and hydrochloric acid solution is 1:30, the extraction temperature is 75°C, extract for 2 hours, filter, and put the filtrate under a vacuum of 0.098Mpa Evaporate to near dryness to obtain a semi-fluid crude extract.

[0057] Step 3: Alcohol precipitation

[0058] Slowly add ethanol to the above crude extract, and keep stirring until the ethanol concentration is 50%, let stand for 48 hours, filter, recover ethanol from the filtrate, and set aside.

[0059] Step Four: Dialysis

[00...

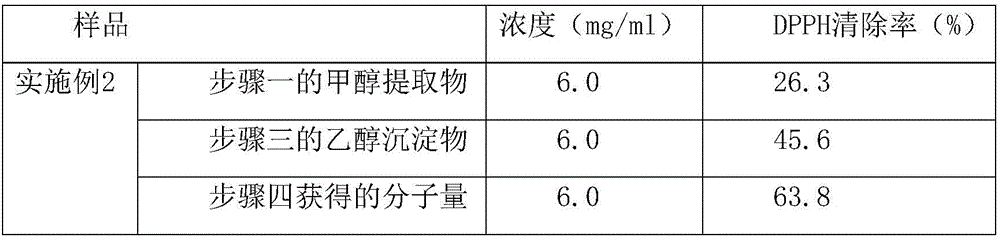

Embodiment 2

[0068] The present embodiment provides a kind of preparation method of seaweed polysaccharide, comprising the following steps:

[0069] Step 1: Remove impurities

[0070] According to the solid-to-liquid ratio g / mL (1:30), the dried and crushed seaweed was refluxed with methanol for 2 hours, filtered, and methanol was recovered from the filtrate;

[0071] Step 2: Extract

[0072] Extract the dried filter residue with 0.2M hydrochloric acid solution, the solid-liquid ratio of the filter residue and hydrochloric acid solution is 1:15, the extraction temperature is 70°C, extract for 4 hours, filter, and put the filtrate under a vacuum of 0.085Mpa Evaporate to near dryness to obtain a semi-fluid crude extract.

[0073] Step 3: Alcohol precipitation

[0074] Slowly add ethanol to the above crude extract, and keep stirring until the ethanol concentration is 30%, let stand for 36 hours, filter, recover ethanol from the filtrate, and set aside.

[0075] Step Four: Dialysis

[007...

Embodiment 3

[0078] The present embodiment provides a kind of preparation method of seaweed polysaccharide, comprising the following steps:

[0079] Step 1: Remove impurities

[0080] According to the solid-to-liquid ratio g / mL (1:25), the dried and pulverized seaweed was refluxed with methanol for 3 hours, filtered, and methanol was recovered from the filtrate;

[0081] Step 2: Extract

[0082] Extract the dried filter residue with 0.1M hydrochloric acid solution, the solid-liquid ratio of filter residue to hydrochloric acid solution is 1:20, the extraction temperature is 70°C, extract for 4 hours, filter, and put the filtrate under a vacuum of 0.085Mpa Evaporate to nearly dryness to obtain a semi-fluid crude extract.

[0083] Step 3: Alcohol precipitation

[0084] Slowly add ethanol to the above crude extract, and keep stirring until the ethanol concentration is 40%, let stand for 24 hours, filter, recover ethanol from the filtrate, and set aside.

[0085] Step Four: Dialysis

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com