Method for preparing high-solid content polycarboxylate superplasticizer

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete admixture, can solve the problems of high process reaction temperature, low production efficiency, high production cost, etc., and achieve the effect of improving storage efficiency, increasing production efficiency and reducing production energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

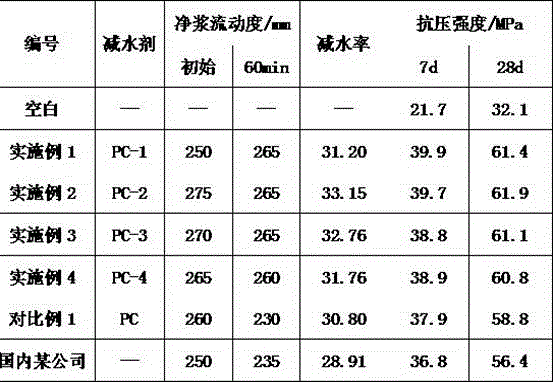

Examples

Embodiment 1

[0021] 1) Dissolve 180g of prenol polyoxyethylene ether in 95g of water at 20°C, pump it to the reactor after the dissolution is complete, and add 1.30g of 25% hydrogen peroxide solution.

[0022] 2) Weigh 1.20g of mercaptopropionic acid, 0.33g of vitamin C and add 28.5g of water in sequence, mix well and drop them into the reaction kettle at a constant speed, and control the dropping time to 3.5h.

[0023] 4) Weigh 20.00g of acrylic acid and dissolve it in 8.55g of water. The solution will be added dropwise after 15min of the mixed solution of mercaptopropionic acid and vitamin C, and the dropping time is 3h.

[0024] 5) After the dropwise addition, heat preservation and aging at 30°C for 1 hour, add 24.69g of 30% sodium hydroxide solution to neutralize the pH of the solution to 6-7, add 59g of water to obtain the product PC-1 of the present invention with a solid content of 50.0% .

Embodiment 2

[0026] 1) Dissolve 180g of methallyl alcohol polyoxyethylene ether in 77g of bottom water at 35°C, pump it to the reaction kettle after it is completely dissolved, and add 1.50g of 30% hydrogen peroxide solution at one time.

[0027] 2) Mix 1.50g of thioglycolic acid and 0.60g of tartaric acid in 19.00g of water, shake well and drop evenly into the reaction kettle, set the dropping time to 3h.

[0028] 3) Weigh 26.00g of acrylic acid and 8.60g of α-hydroxyethyl acrylate, add 11.53g of water, and mix evenly. After 15 minutes of adding the mixture in 2), start adding dropwise, and set the dropping time to 2.5h.

[0029] 4) After the dropwise addition, heat preservation and aging at 30°C for 1 hour, add 30.09g of 30% sodium hydroxide solution until the pH of the solution is 6-7, and add 22.00g of water to obtain the product PC-2 of the present invention with a solid content of 60.0%. .

Embodiment 3

[0031] 1) Add 180g of prenol polyoxyethylene ether to 120g of water, dissolve completely at 40°C and add 2g of 30% hydrogen peroxide solution at one time.

[0032] 2) Weigh 1.17g of mercaptopropionic acid and 0.60g of vitamin C, add 15.90g of water and shake well, set the dropping time to 3.5h.

[0033] 3) Weigh 25.00g of acrylic acid and 15.00g of acrylamide, dissolve them in 21.50g of water, shake well until the dissolution is complete, add the mixed solution in 2) dropwise for 15 minutes, and then start adding the mixed solution dropwise, and set the dropping time to 3h.

[0034] 4) After the dropwise addition, heat preservation and aging at 30°C for 1 hour, add 23.15g of 40% sodium hydroxide solution to neutralize the pH of the solution to 6-7, add 16.50g of water to obtain the product PC- 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com