Method for preparing fishing line from sisal hemp fiber and polyethylene fiber composite material

A polyethylene fiber and sisal fiber technology, which is applied in fiber type, fiber treatment, plant fiber, etc., can solve the problems of easy broken wire and small elongation at break of hollow fishing line, and achieve easy rearrangement and improved mechanical properties , tensile strength and modulus of elasticity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

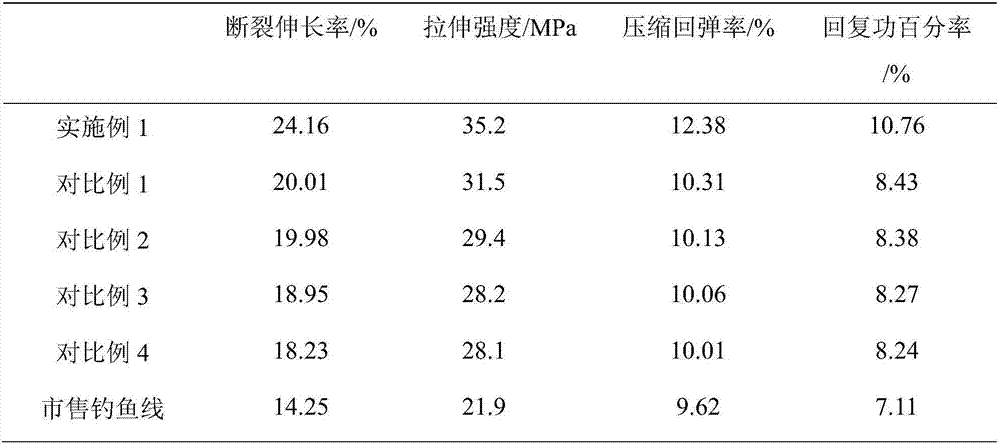

Examples

Embodiment 1

[0022] A kind of method that sisal fiber polyethylene fiber composite material prepares fishing line, comprises the following steps:

[0023] S1, soaking the sisal fiber in a hydrogen peroxide solution with a mass fraction of 5% for 20 minutes and taking it out to obtain the pretreated sisal fiber;

[0024] S2. Soak the ultra-high molecular weight polyethylene fiber in a potassium permanganate solution with a mass fraction of 1.5% for 30 minutes and take it out to obtain the pretreated ultra-high molecular weight polyethylene fiber;

[0025] S3. Mix the pretreated sisal fiber in S1 and the pretreated ultra-high molecular weight polyethylene fiber in S2 at a mass ratio of 1:2 to obtain a mixed fiber, and put the mixed fiber into a quick freezer at a temperature of -18°C Freeze for 10 minutes, then take it out and put it in a sodium acetate solution at a temperature of 35°C, continue to heat the sodium acetate solution to 50°C within 3 minutes, then stop heating and continue soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com