Yb2Si2O7 crystal whiskers and preparation method thereof

A whisker, 3·5H2O technology, applied in the field of Yb2Si2O7 whisker and its preparation, can solve the problems of harsh reaction conditions, complex preparation process, long reaction cycle, etc., and achieve shortened reaction time, simple process, easy shape and size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

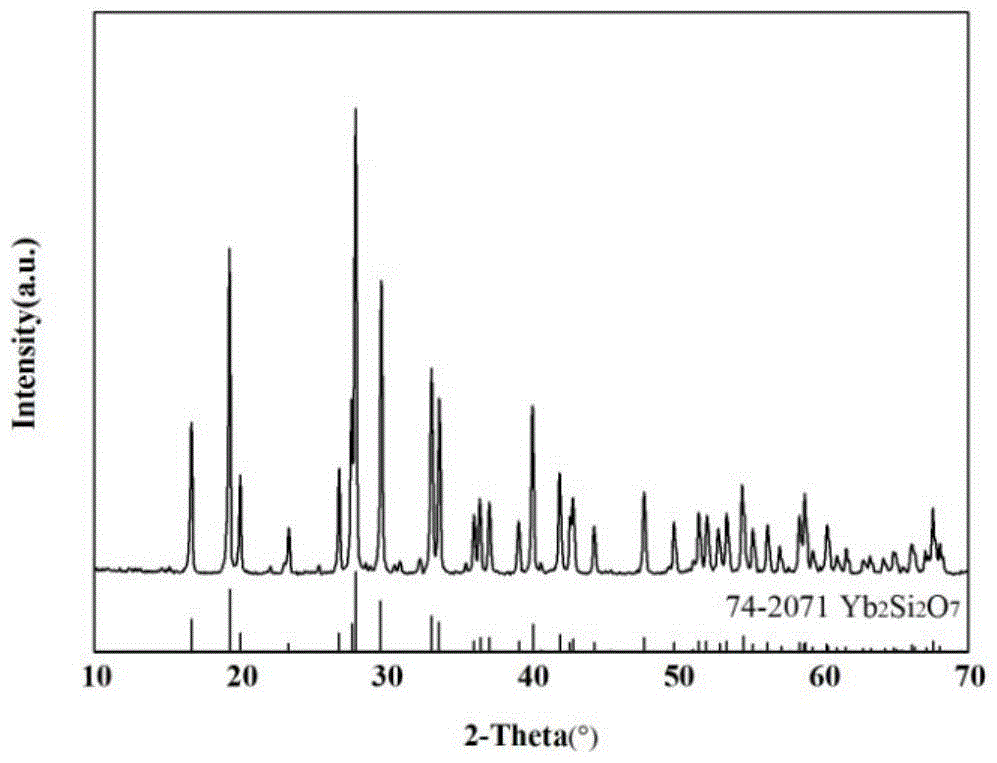

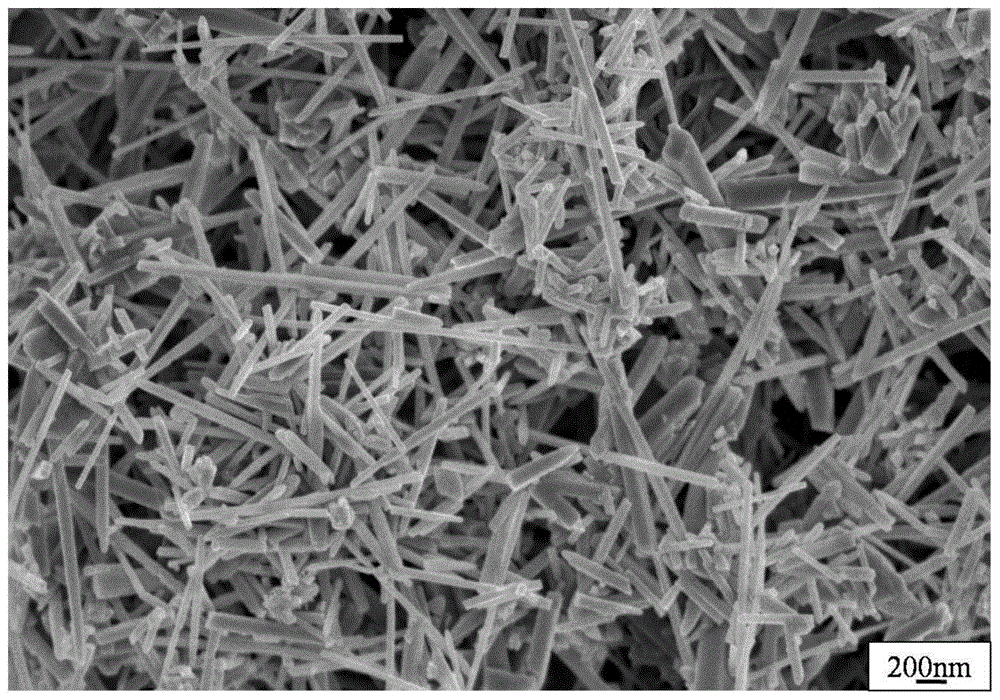

Image

Examples

Embodiment 1

[0028] a Yb 2 Si 2 o 7 The preparation method of whisker, comprises the following steps:

[0029] 1) Weigh analytically pure Yb(NO) 3 ·5H 2 O, fully dissolved in absolute ethanol, prepared into a solution with a concentration of 0.05mol / L, and the obtained solution was designated as solution A.

[0030] 2) Take analytically pure TEOS (Si(OC 2 h 5 ) 4 ), according to Yb(NO) 3 ·5H 2 The molar ratio of O:TEOS=1:1, the measured amount of TEOS was added to the solution A, and the solution B was obtained after fully stirring for 1 hour.

[0031]3) Put solution B into a constant temperature reactor, control the temperature at 60°C, and dry for 10 hours to obtain powder A.

[0032] 4) Put the dried powder A into a crucible, place it in a muffle furnace at 200°C for 1 hour pre-calcination, wait for natural cooling to room temperature, and obtain powder B after taking it out.

[0033] 5) Choose commercially available analytically pure sodium chloride (NaCl) and potassium chlo...

Embodiment 2

[0036] a Yb 2 Si 2 o 7 The preparation method of whisker, comprises the following steps:

[0037] 1) Weigh analytically pure Yb(NO) 3 ·5H 2 O, fully dissolved in absolute ethanol, prepared into a solution with a concentration of 0.1mol / L, and the obtained solution was designated as solution A.

[0038] 2) Take analytically pure TEOS (Si(OC 2 h 5 ) 4 ), according to Yb(NO) 3 ·5H 2 The molar ratio of O:TEOS=1:1, the measured amount of TEOS was added to the solution A, and the solution B was obtained after fully stirring for 1.5h.

[0039] 3) Put solution B into a constant temperature reactor, control the temperature at 60°C, and dry for 8 hours to obtain powder A.

[0040] 4) Put the dried powder A into a crucible, place it in a muffle furnace at 200°C for pre-calcination for 2 hours, cool it down to room temperature naturally, and take it out to obtain powder B.

[0041] 5) Choose commercially available analytically pure sodium chloride (NaCl) and potassium chloride ...

Embodiment 3

[0044] a Yb 2 Si 2 o 7 The preparation method of whisker, comprises the following steps:

[0045] 1) Weigh analytically pure Yb(NO) 3 ·5H 2 O, fully dissolved in absolute ethanol, prepared into a solution with a concentration of 0.1mol / L, and the obtained solution was designated as solution A.

[0046] 2) Take analytically pure TEOS (Si(OC 2 h 5 ) 4 ), according to Yb(NO) 3 ·5H 2 The molar ratio of O:TEOS=1:1.5, the measured amount of TEOS was added to the solution A, and the solution B was obtained after fully stirring for 1 hour.

[0047] 3) Put solution B into a constant temperature reactor, control the temperature at 60°C, and dry for 8 hours to obtain powder A.

[0048] 4) Put the dried powder A into a crucible, place it in a muffle furnace at 200°C for pre-calcination for 3 hours, let it cool down to room temperature naturally, and take it out to obtain powder B.

[0049] 5) Choose commercially available analytically pure sodium chloride (NaCl) and potassium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com