Paper cup lid and its manufacturing process

A manufacturing process and technology for paper cups, which are applied in the field of paper cup lids and their production processes, can solve the problems of poor bonding ability and low strength performance of paper cup lids, and achieve the effect of excellent strength performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

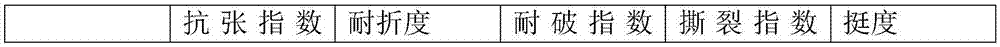

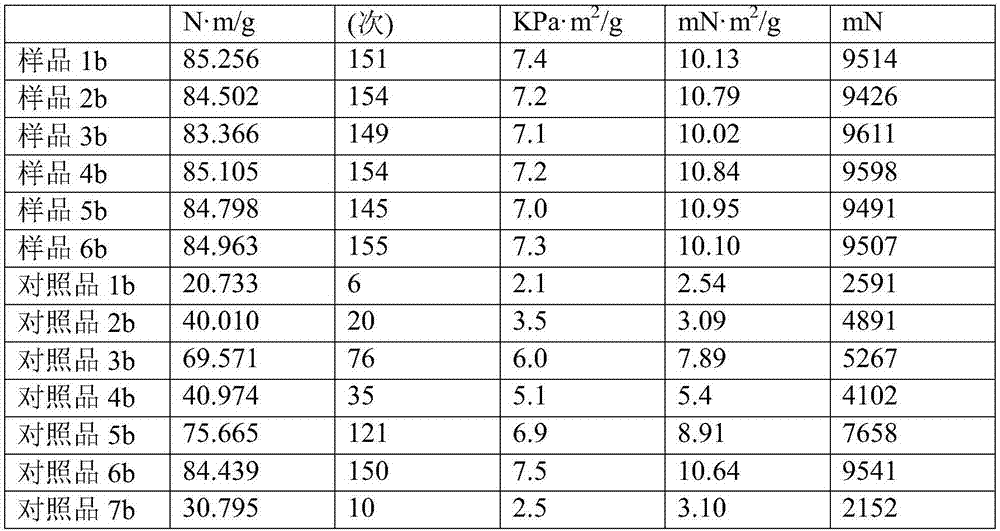

Embodiment 1

[0033] Dissolve 1Kg of sodium alginate in 3Kg of water to obtain an aqueous solution of sodium alginate; process 90Kg of bagasse pulp through beating and refining; add the obtained aqueous solution of sodium alginate to the obtained slurry under stirring conditions, Mix evenly; add 0.5Kg titanium dioxide, 5Kg diatomaceous earth, and 0.5Kg tea polyphenols in turn under the condition of stirring, and mix evenly; inject it into the mold of the cup cover, under the mold pressing state, at a temperature of 185-200°C Under the condition of heating and drying for 2 to 3 minutes; after that, use a trimmer to trim the edge to obtain the sample 1a.

[0034] Dissolve 1Kg of sodium alginate in 3Kg of water to obtain an aqueous solution of sodium alginate; process 90Kg of bagasse pulp through beating and refining; add the obtained aqueous solution of sodium alginate to the obtained slurry under stirring conditions, Mix evenly; add 0.5Kg titanium dioxide, 5Kg diatomaceous earth, and 0.5Kg t...

Embodiment 2

[0035] Embodiment 2: Carry out according to the method of embodiment 1, obtain sample 2a and sample 2b respectively. The difference is the feeding of each component: bagasse slurry 95Kg, tea polyphenol 0.5Kg, sodium alginate 0.5Kg, titanium dioxide 0.5Kg, diatomite 3Kg, water 0.5Kg.

Embodiment 3

[0036] Embodiment 3: Carry out according to the method of embodiment 1, obtain sample 3a and sample 3b respectively. The difference is the feeding of each component: bagasse pulp 92Kg, tea polyphenol 1Kg, sodium alginate 0.7Kg, titanium dioxide 0.8Kg, diatomite 3Kg, water 2.5Kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com