Hydrogel microsphere fluorescence sensor as well as preparation method and application thereof

A fluorescence sensor, hydrogel microsphere technology, applied in fluorescence/phosphorescence, instruments, scientific instruments, etc., can solve the problems of rapid detection of limited ions, harsh detection requirements, expensive detection costs, etc., to achieve high sensitivity and great application prospects , the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Preparation of hydrogel precursor solution and oil phase and preparation of microspheres

[0046] 3g PEG-DA, 2.7g HEPES buffer and 0.3g photoinitiator (2-hydroxy-2-methyl-1-phenyl-1-propanone) were thoroughly mixed to prepare a hydrogel solution. The fluorescent probe was dissolved in DMSO to a concentration of 1mMol / L. The probe solution was diluted and mixed with the DMSO solution of the probe and the HEPES buffer according to the volume ratio of 1:5. The hydrogel precursor solution was fully mixed with the hydrogel solution and the probe solution at a volume ratio of 1:5, and was ultrasonically prepared. The oil phase consists of 60%-99% organic solvents including n-decane, n-hexane, n-octane or n-butane, etc., mixed with 10-25% oil-soluble surfactants such as Span20, Span40, Span60, Span80, Tween85 or Alkyl tertiary amine salts, etc., mixed thoroughly, ultrasonically removed air bubbles, set aside.

[0047]Use two syringes to absorb the appropriate a...

Embodiment 2

[0048] The microsphere sensor that embodiment 2 makes is to the selectivity of metal ion

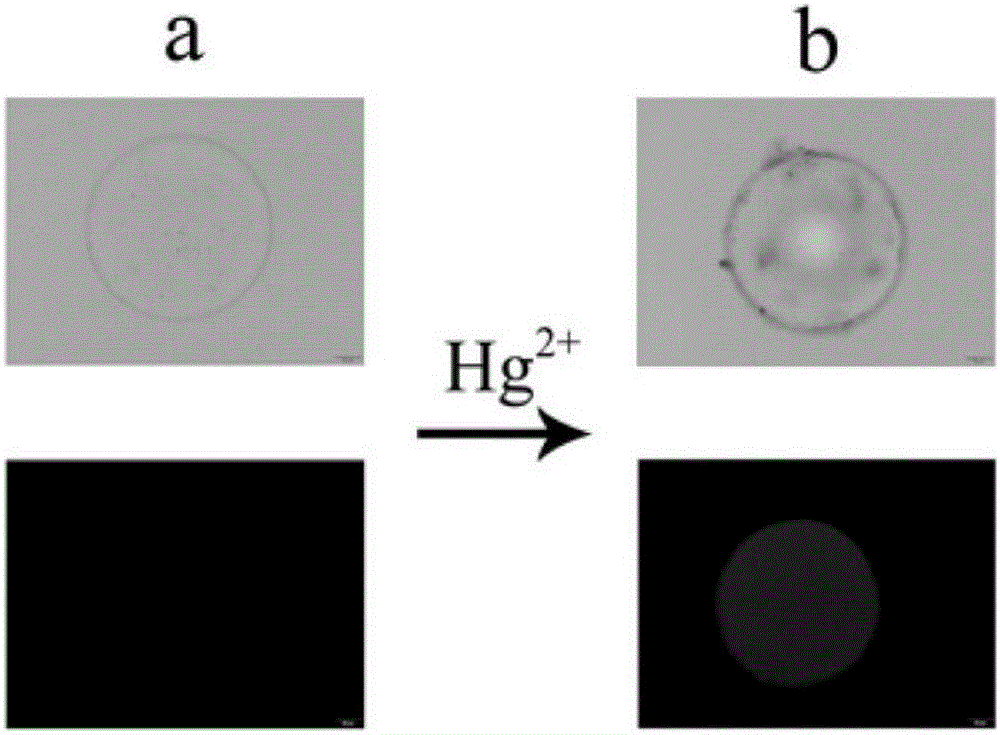

[0049] Take the microsphere sensor prepared in Example 1, draw one and place it in a 96-well plate, then add mercury ions, let it stand at room temperature for 5 minutes, and take optical images and fluorescence images under a fluorescence microscope. The result is as figure 1 shown.

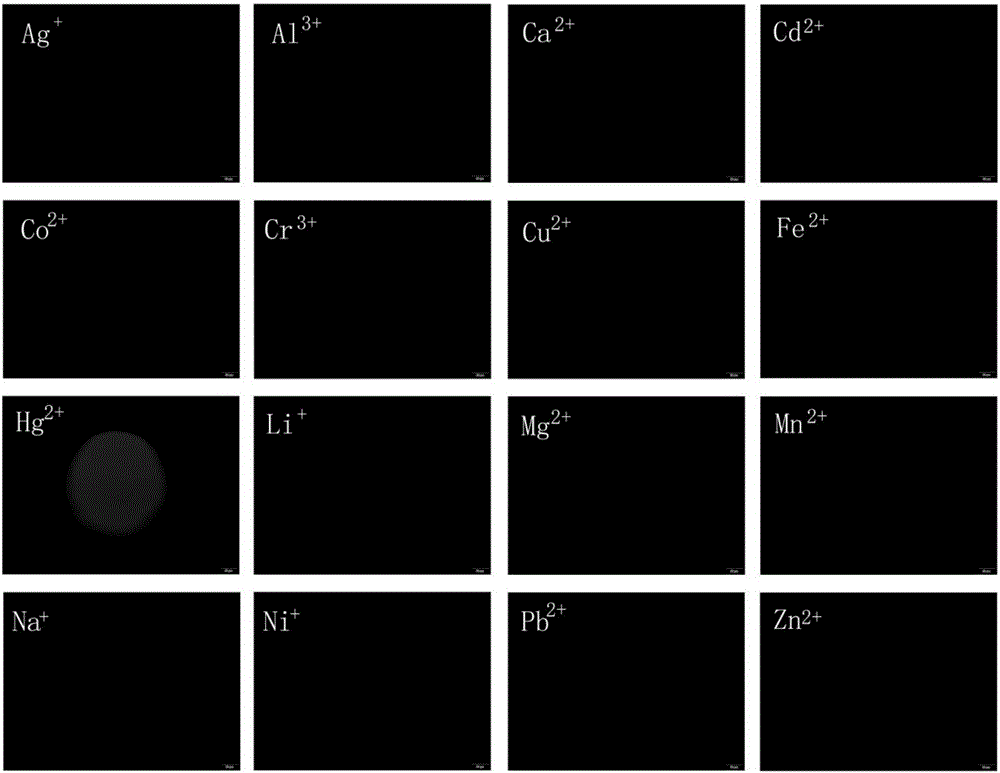

[0050] Prepare the following metal ion solutions: Cu 2+ ,Pb 2+ , Na + ,Hg 2+ , Fe 2+ ,Mn 2+ ,Cr 3+ ,Co 2+ ,Zn 2+ ,Mg 2+ , Li + , Ni 2+ ,Cd 2+ , Ag + , Ca 2+ and Al 3+ , the concentration is 1 μMol / L. Select 16 wells on a 96-well plate and inject 0.2 mL each of the above metal ions. Then, put one microsphere of Example 1 into each well, let it stand for 5 minutes, and take a fluorescent image under a fluorescent microscope, and the conditions such as exposure time and light intensity are uniform. The result is as figure 2 shown.

[0051] The above results show that: the microsphere sen...

Embodiment 3

[0052] Fluorescence analysis of the microsphere sensor and mercury ion made in embodiment 3

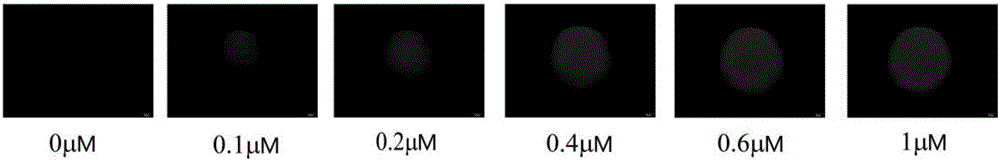

[0053] Prepare mercury ions at 0 μM, 0.1 μM, 0.2 μM, 0.4 μM, 0.6 μM, and 1.0 μM. Pipette 0.2 mL of the above-mentioned mercury ion solution into a 96-well plate, and then put microsphere sensors in each well, let it stand for 5 minutes, and take fluorescence images under a fluorescence microscope. The result is as image 3 shown.

[0054] The relationship between mercury ion concentration and fluorescence intensity. The fluorescence microscope selects the grayscale mode, and then takes grayscale pictures at mercury ion concentrations of 0μM, 0.2μM, 0.4μM, 0.6μM and 0.8μM, and calculates the grayscale value in the same area of each picture, which is the fluorescence intensity. Make a graph of concentration versus fluorescence intensity. The result is as Figure 4 shown.

[0055] The microsphere sensor of Example 1 was placed in the wells of the 96-well plate, placed on the obse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com