Quick-dry type silver paste used for PCB through hole and preparation method for quick-dry type silver paste

A quick-drying, silver paste technology, applied in cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc., can solve problems such as low production efficiency, high curing temperature, and inapplicability. Achieve the effects of improving wear resistance, no three wastes pollution, and preventing sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

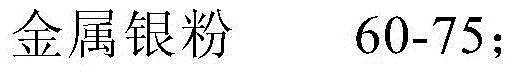

[0029] (1) Material preparation: Prepare materials according to the following components: 30kg of metallic silver powder, 4kg of polymer resin, 1kg of organic additive, and 15kg of organic solvent. The metal silver powder used is micron silver powder and nano silver powder, wherein the metal silver powder includes 20kg of micron silver powder, 10kg of nano silver powder, the particle size of the micron silver powder is 5μm, the tap density is 2.5g / ml, and the particle size of the nano silver powder is 135nm. The density is 2.8g / ml. The polymer resin used is polyurethane resin. The organic additives used include 0.2 kg of sealing curing agent, 0.2 kg of thickening agent fumed silica, 0.2 kg of hardening agent conductive graphite, 0.1 kg of silane coupling agent KH5500, and 0.3 kg of leveling agent silicone resin. The organic solvent used contains 2kg of methyl ethyl ketone, 2kg of ethylene glycol ether acetate, 3kg of isophorone, and 8kg of divalent ester

[0030] (2) The con...

Embodiment 2

[0034] (1) Material preparation: Prepare materials according to the following components: 36kg of metallic silver powder, 4.8kg of polymer resin, 1.2kg of organic additives, and 18kg of organic solvent. The metal silver powder used is micron silver powder and nano silver powder, wherein the metal silver powder contains 24kg of micron silver powder, 12kg of nano silver powder, the average particle size of the micron silver powder is 5.8μm, the tap density is 2.6g / ml, and the particle size of the nano silver powder is 165nm. The tap density is 2.7 g / ml. The polymer resin used is polyurethane resin. The organic additives used include 0.24 kg of sealing curing agent, 0.24 kg of thickening agent fumed silica, 0.24 kg of hardening agent conductive graphite, 0.12 kg of silane coupling agent KH5500, and 0.36 kg of leveling agent silicone resin. The organic solvent used contains 2.4kg of methyl ethyl ketone, 2.4kg of ethylene glycol ether acetate, 3.6kg of isophorone, and 9.6kg of dib...

Embodiment 3

[0039](1) Material preparation: Prepare materials according to the following components: 15kg of metallic silver powder, 2kg of polymer resin, 0.5kg of organic additive, and 7.5kg of organic solvent. The metal silver powder used is micron silver powder and nano silver powder, wherein the metallic silver powder includes 10kg of micron silver powder and 5kg of nano silver powder, the average particle size of the micron silver powder is 6.0 μm, and the tap density is 2.3 g / ml. The polymer resin used is polyurethane resin. The organic additives used include 0.1kg of sealing curing agent, 0.1kg of thickening agent fumed silica, 0.1kg of hardening agent conductive graphite, 0.05kg of silane coupling agent KH550, KH560, KH570, and leveling agent silicone resin 0.15kg. The organic solvent used contains 1kg of methyl ethyl ketone, 1kg of ethylene glycol ether acetate, 1.5kg of isophorone, and 4kg of divalent ester

[0040] (2) The configuration of the carrier: Weigh the polyurethane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com