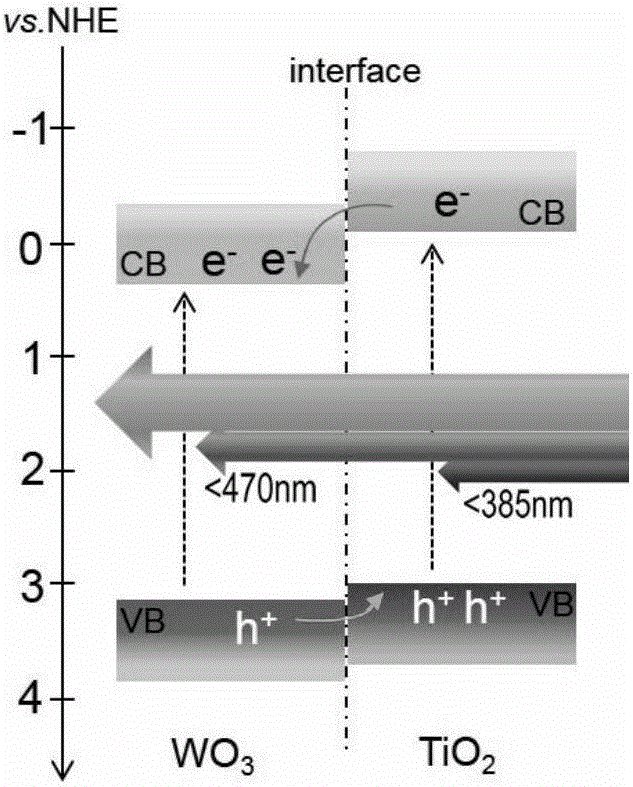

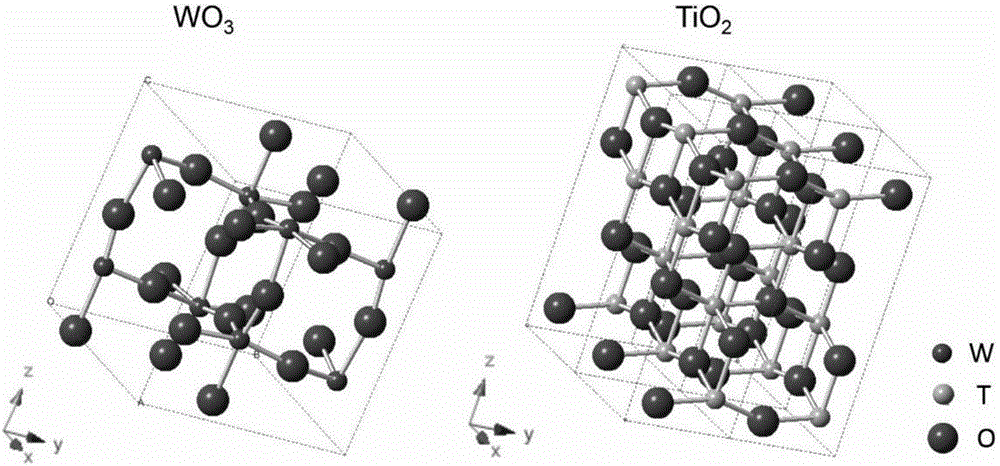

Tungsten trioxide/titanium dioxide nano heterojunction thin film and preparation and application thereof

A tungsten trioxide and titanium dioxide technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of serious charge recombination and poor film stability, and achieve suitable The effect of large area preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

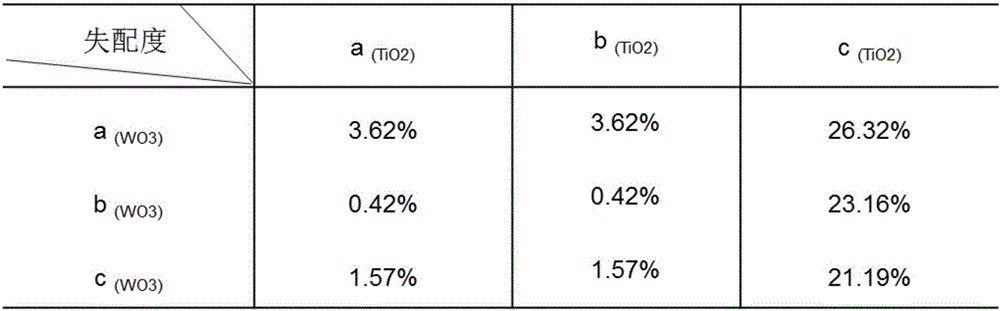

Method used

Image

Examples

Embodiment 1

[0039] Preparation of WO by chemical bath method 3 Nanosheet film (Zhou Baoxue et al., a kind of WO 3 Nanosheet array film preparation method and its application research, Chinese patent application number: 201510724443.X): in the presence of 0.4gNa 2 WO 4 2H 2 O, 0.15g ammonium oxalate 9mL37% hydrochloric acid, 8mL37% H 2 o 2 and 30mL of ethanol in 30mL of deionized aqueous solution, the tungstic acid film obtained on the conductive glass substrate was obtained in a water bath at 85°C for 200min, and then heat-treated at 500°C for 2h. 3 Nanosheet films (see Figure 4 A). This WO 3 The nanosheet film is placed in an aqueous solution containing 15mM ammonium fluotitanate and 75mM boric acid, and treated at a constant temperature of 35°C for 7h, the film is taken out and rinsed with deionized water for more than 1min, and then dried naturally to obtain nano-WO 3 / TiO 2 heterojunction films.

[0040] From Figure 4 B It can be seen that the prepared nano-WO 3 / TiO 2 ...

Embodiment 2

[0046] Preparation of WO by hydrothermal method 3 Nanosheet film (Zhou Baoxue et al., a tungsten-based tungsten trioxide film and its preparation method and application, Chinese patent authorization number: CN102674463B): an aqueous solution containing 30mM sodium tungstate, 10% polyethylene glycol 300, pH=2.5 As the precursor solution, put the heat-treated tungsten sheet in it, and heat it in water at 180°C for 2h. The obtained film was heat-treated at 500 °C for 2 h to obtain WO 3 Nanosheet films (see Figure 5 A). This WO 3 The nanosheet film is placed in an aqueous solution containing 10mM ammonium fluotitanate and 50mM boric acid, and treated at a constant temperature of 50°C for 1h, the film is taken out and rinsed with deionized water for more than 1min, and the nano-WO is obtained after natural drying. 3 / TiO 2 heterojunction thin film, which also has a uniform TiO 2 Nanothorn structure (see Figure 5 B). The film material can be used as a photocatalytic electr...

Embodiment 3

[0048] Preparation of WO by hydrothermal method 3 Nanorod film (Zhou Baoxue, etc., a tungsten-based tungsten trioxide film and its preparation method and application, Chinese patent authorization number: CN102674463B): an aqueous solution containing 20mM sodium tungstate, 10% polyethylene glycol 300, pH=2.5 As the precursor solution, put the heat-treated tungsten sheet in it, and heat it in water at 180°C for 6h. The obtained film was heat-treated at 500 °C for 2 h to obtain WO 3 nanorod films (see Figure 6 A). This WO 3 The nanorod film was placed in an aqueous solution containing 20mM ammonium fluotitanate and 100mM boric acid, and treated at a constant temperature of 25°C for 70h, the film was taken out and rinsed with deionized water for more than 1min, and the nano-WO was obtained after natural drying. 3 / TiO 2 heterojunction thin film, which also has a uniform TiO 2 Nanothorn structure (see Figure 6 B). The thin film material can be used as a sensing material f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com