Three-dimensional graphene composite electrode with surface carrying flowerlike Ni3S2 and preparation method and application thereof

A composite technology of nickel disulfide and graphene, applied in the direction of negative electrode, battery electrode, secondary battery, etc., to achieve the effect of improving cycle stability, short cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

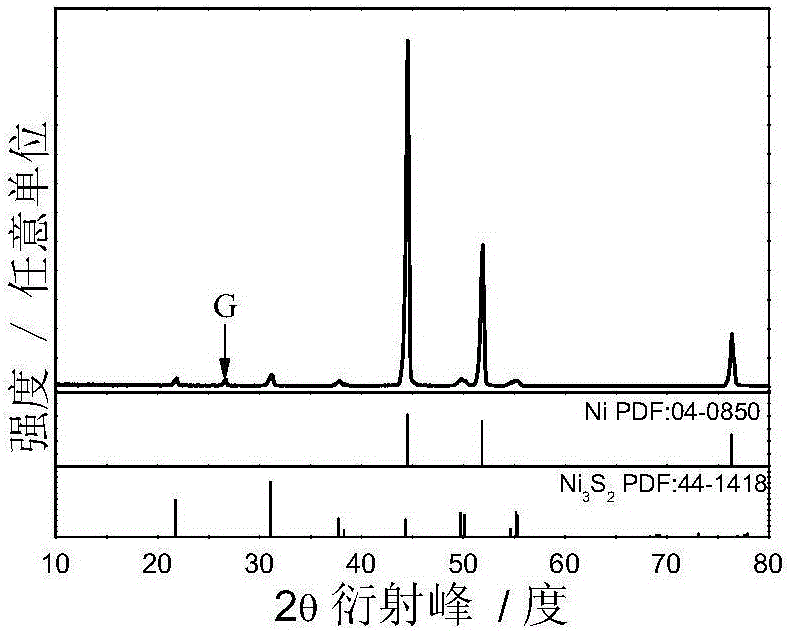

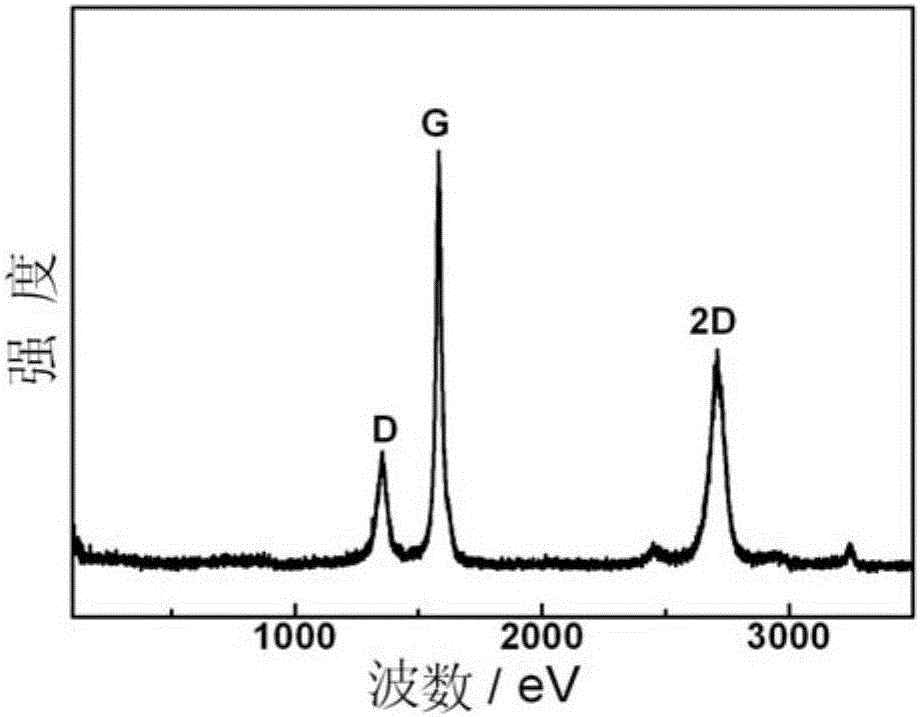

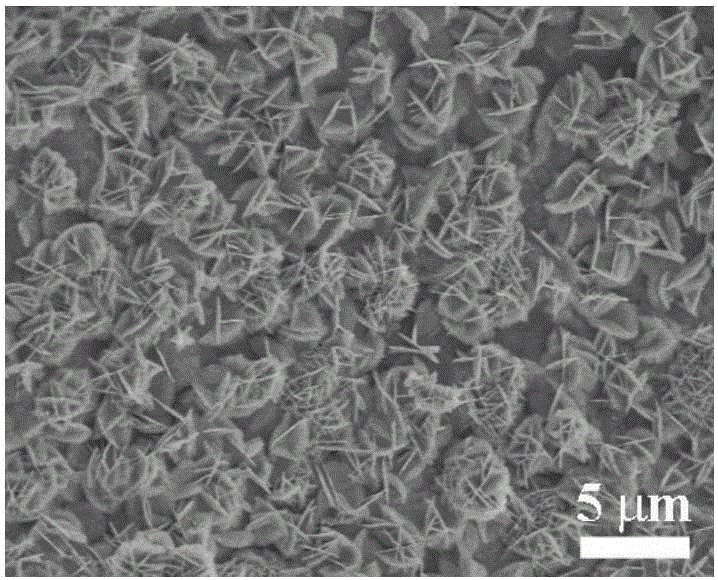

[0035] Put nickel foam into a tube furnace, and raise the temperature to 1000°C at a heating rate of 100°C / min under an Ar (500s.c.c.m.) atmosphere; after holding for 5 minutes, introduce methane into the quartz tube with an Ar (250s.c.c.m.) flow , reacted for 5 minutes; finally, cooled to room temperature at a cooling rate of 100°C / min under an Ar atmosphere to obtain three-dimensional graphene (Ni / G) grown on a nickel foam substrate, wherein the loading capacity of graphene was 0.485mg / cm 2 ; Thiourea (the molar weight is 0.4 times of anhydrous sodium sulfate) and anhydrous sodium sulfate are dissolved in deionized water, stir well, and prepare SO 4 2–A solution with a concentration of 0.03mol / L; Ni / G is used as a matrix, immersed in the above solution, and then transferred into a reaction kettle, sealed and kept in an oven at 120°C for 3 hours, and then rinsed with deionized water and absolute alcohol Several times, after vacuum drying in an oven at 60 °C for 12 hours, the...

Embodiment 2

[0046] Put nickel foam into a tube furnace, and raise the temperature to 1000°C at a heating rate of 100°C / min under an Ar (500s.c.c.m.) atmosphere; after holding for 5 minutes, introduce methane into the quartz tube with an Ar (250s.c.c.m.) flow , reacted for 8 minutes; finally, cooled to room temperature at a cooling rate of 100°C / min under an Ar atmosphere to obtain three-dimensional graphene (Ni / G) grown on a nickel foam substrate, wherein the graphene loading capacity was 0.51mg / cm 2 ; Thiourea (0.2 of the molar mass of anhydrous sodium sulfate) and anhydrous sodium sulfate are dissolved in deionized water, stirred evenly, and prepared with SO 4 2– A solution with a concentration of 0.05mol / L; use Ni / G as a matrix, immerse in the above solution, then transfer it into a reaction kettle, seal it and keep it in an oven at 110°C for 4 hours, and then rinse it with deionized water and absolute alcohol Several times, after vacuum drying in an oven at 60 °C for 12 hours, the su...

Embodiment 3

[0050] Put nickel foam into a tube furnace, and raise the temperature to 1000°C at a rate of 100°C / min under an Ar (500s.c.c.m.) atmosphere; after holding for 5 minutes, introduce ethanol into the quartz tube with an Ar (250s.c.c.m.) airflow , reacted for 3 minutes; finally, cooled to room temperature at a cooling rate of 100°C / min under Ar atmosphere to obtain three-dimensional graphene (Ni / G) grown on a nickel foam substrate, wherein the graphene loading capacity was 0.32mg / cm 2 ; Thiourea (0.6 of the molar mass of anhydrous sodium sulfate) and anhydrous sodium sulfate are dissolved in deionized water, stirred evenly, and prepared with SO 4 2– A solution with a metered concentration of 0.02mol / L; Ni / G is used as a matrix, immersed in the above solution, then transferred into a reaction kettle, sealed and kept in an oven at 130°C for 2 hours, and then rinsed with deionized water and absolute alcohol Several times, after vacuum drying in an oven at 60 °C for 12 hours, the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com