Microwave absorber composite material capable of achieving full frequency band absorption within range of 2-8 GHz

A technology of composite materials and microwave absorbing materials, which is applied in the field of absorber composite materials, can solve problems such as poor low-frequency absorption effect, difficulty in full-band absorption, narrow stealth frequency band, etc., and achieve the effect of widening the absorption bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

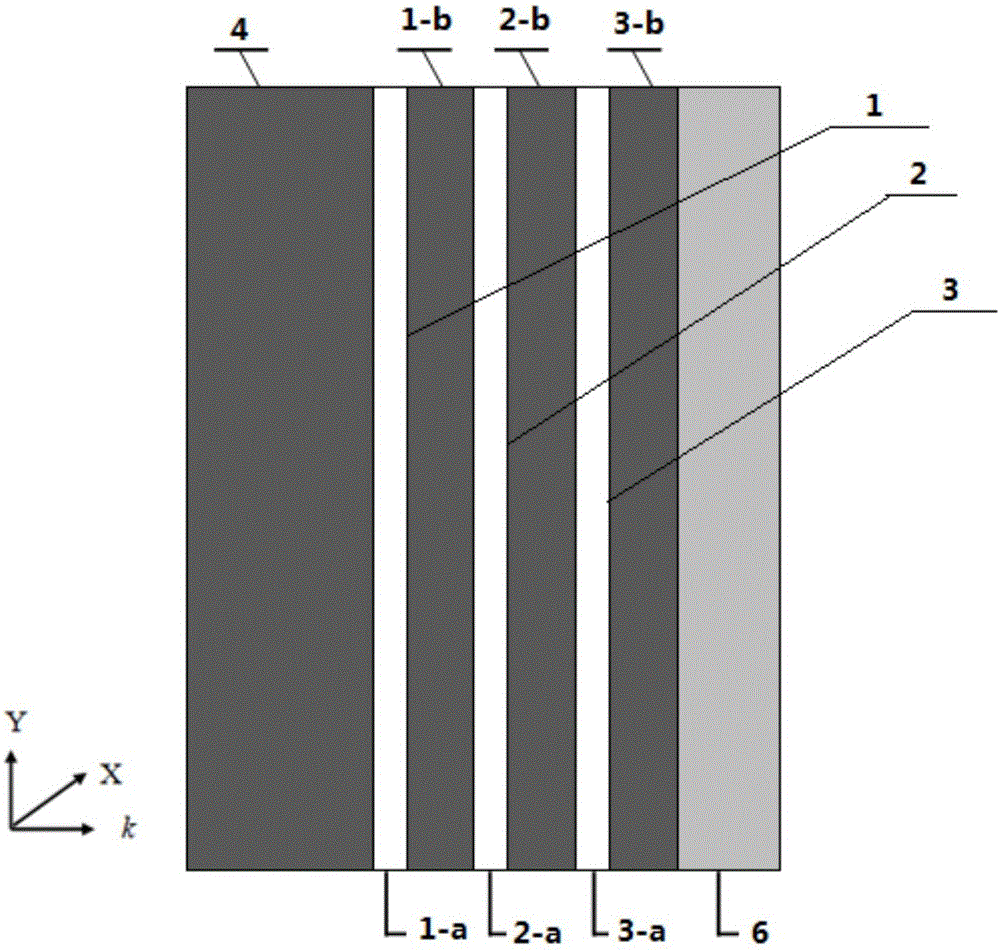

[0016] An absorber composite material that can achieve full-band absorption from 2 to 8GHz, such as figure 1 As shown, the k direction in the figure is the incident direction of electromagnetic waves, X is the direction of the electric field, and Y is the direction of the magnetic field; the three base units 1, 2 and 3 are superimposed from top to bottom, and the structures of the three base units are basically the same. One side of the microstructure material 1-a is coated with a microwave absorbing material with a thickness of 0.5 mm to form a microwave absorbing coating 1-b to form the base unit 1, and one side of the rectangular microstructure material 2-a is coated with a microwave absorbing coating with a thickness of 0.5 mm. The microwave absorbing material forms the microwave absorbing coating 2-b to form the base unit 2, and the microwave absorbing coating 3-b formed by the microwave absorbing material is coated with a thickness of 0.5mm on one side of the rectangular ...

Embodiment 2

[0018] The absorber composite material of embodiment 1 is prepared by the following method:

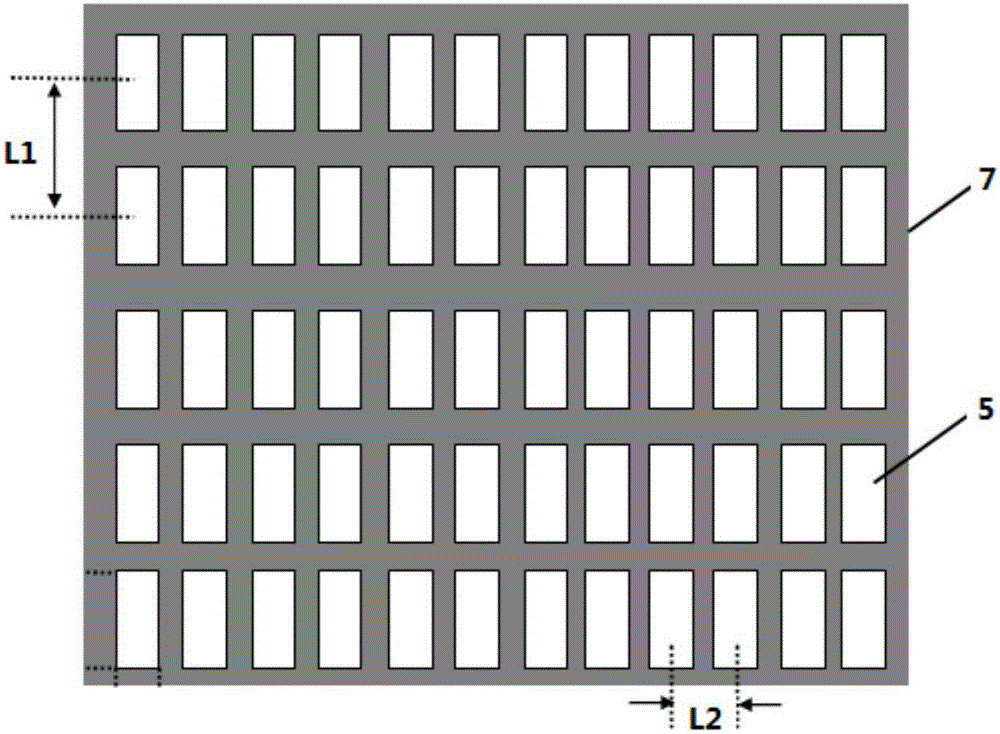

[0019] First, according to the design requirements that the distance between the upper and lower two adjacent metal copper sheets 5 is 10 mm, and the distance between the left and right two adjacent metal copper sheets 5 is 2.2 mm, the printing method in the prior art is applied on the glass fiber board. Cover its two sides with a rectangular metal copper sheet 5 with a thickness of 0.01mm to make three rectangular microstructure materials. The length of the rectangular metal copper sheet 5 of a rectangular microstructure material is 9.5mm and the width is 2.2mm. The length of the rectangular metal copper sheet 5 of the material is 6.8mm, and the width is 2.2mm, and the length of the rectangular metal copper sheet 5 of the third rectangular microstructure material is 5mm, and the width is 2.2mm; The powder and the binder epoxy resin are fully mixed in a mass ratio of 1:3 and then spra...

Embodiment 3

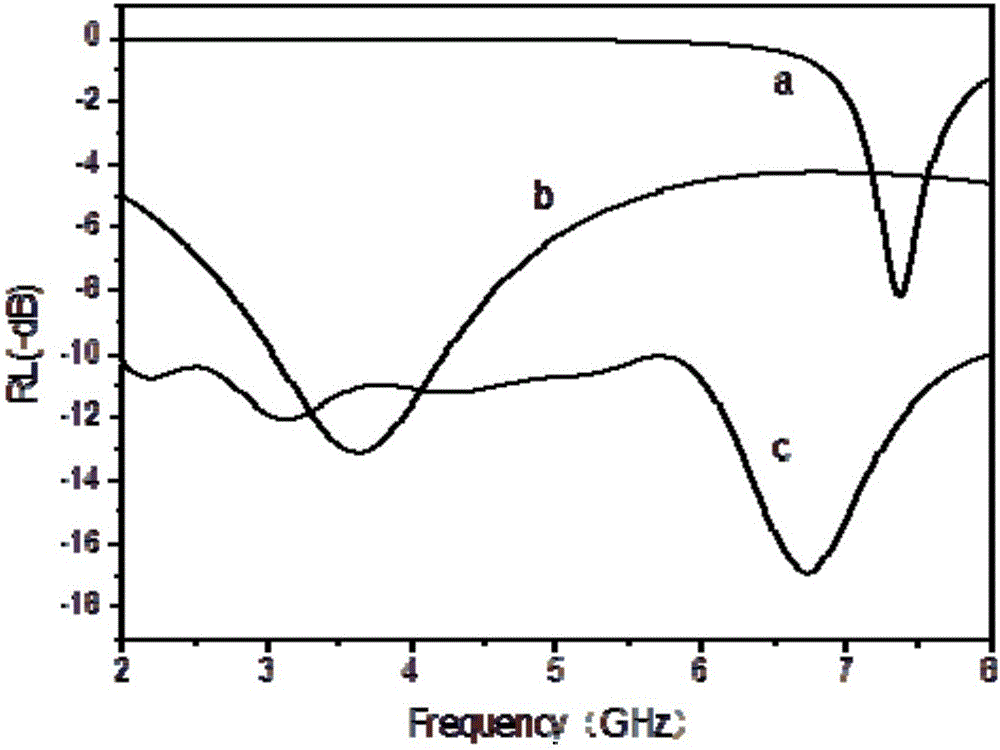

[0021] The frequency-reflection loss curves of the following three materials are measured respectively by the bow-shaped frame method, a single three-layer, single microwave-absorbing material carbonyl iron powder coating (thickness) composed of three rectangular microstructure materials as in Example 2 3.4mm) and the composite microwave absorbing material of embodiment 1, the results are shown in image 3 , in the figure a is the reflection loss curve of rectangular microstructure material with frequency, b is the reflection loss curve of traditional microwave absorbing material carbonyl iron powder coating with frequency, and c is the reflection loss curve of composite microwave absorbing material with frequency Curve. From image 3 It can be seen that the absorption peak of the rectangular microstructure material appears at 7.25GHz, and the reflection loss does not reach -10dB. The absorption frequency band is 3.4mm thick and the carbonyl iron powder microwave absorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com