Method for preparing differently morphological hydroxyapatite by using waste shell

A hydroxyapatite and morphology technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of long synthesis time, complex process steps, high preparation cost, and achieve good ion adsorption and exchangeability, The effect of reducing the reaction conditions and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

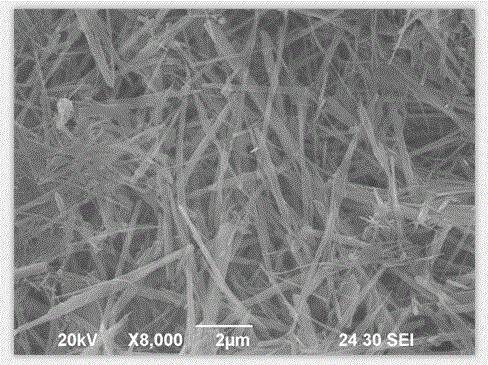

[0031] Such as figure 1 As shown, respectively weigh 1.00 g of shell powder and 0.792 g of diammonium hydrogen phosphate according to the calcium-phosphorus atomic ratio of 1.67, add them into 250 ml of distilled water to fully dissolve, and stir evenly. Slowly add ammonia water dropwise to the mixed reaction solution to adjust the pH, so that the pH=9-10. The adjusted reaction mixture solution was placed in a water bath for heating, and kept at a constant temperature for 2 hours when the temperature reached 95° C., and cooled after the reaction was complete. Suction filter the reactant cooled to room temperature, wash with distilled water and absolute ethanol in sequence, and finally put it into a constant temperature drying oven, keep the temperature at 105°C and dry for 8 hours to obtain ribbon-shaped hydroxyapatite powder.

example 2

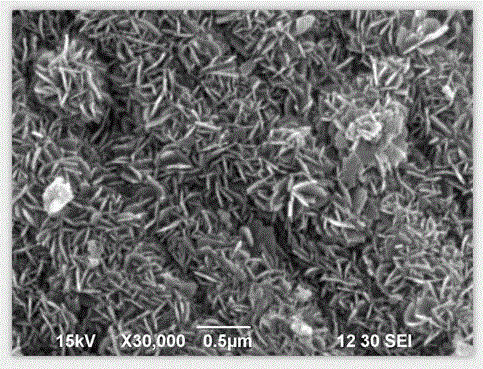

[0033] Such as figure 2 As shown, weigh 1.00g of shell powder, 0.396g of diammonium hydrogen phosphate, and 0.345g of ammonium dihydrogen phosphate according to the calcium-phosphorus atomic ratio of 1.67, add them into 250ml of distilled water to fully dissolve, and stir evenly. Slowly add ammonia water dropwise to the mixed reaction solution to adjust the pH, so that the pH=11-12. The adjusted reaction mixture solution was placed in a water bath for heating, and kept at a constant temperature for 3 hours when the temperature reached 85° C., and cooled after the reaction was complete. Suction filter the reactant cooled to room temperature, wash with distilled water and absolute ethanol in sequence, and finally put it into a constant temperature drying oven, keep the temperature at 100°C and dry for 4 hours to obtain flaky hydroxyapatite powder.

example 3

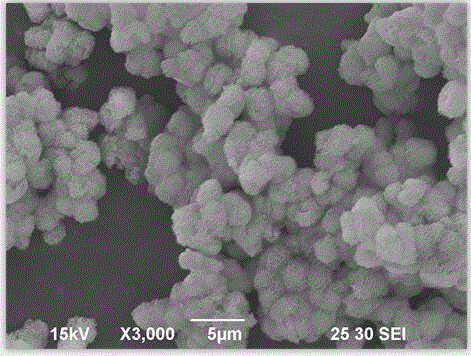

[0035] Such as image 3 As shown, weigh 1.00g of shell powder, 6.6g of diammonium hydrogen phosphate, and 1.15g of ammonium dihydrogen phosphate according to the calcium-phosphorus atomic ratio of 1.67, add them into 250ml of distilled water to fully dissolve, and stir evenly. Slowly add ammonia water dropwise to the mixed reaction solution to adjust the pH, so that the pH=13-14. The adjusted reaction mixture solution was placed in a water bath for heating, and kept at a constant temperature for 4 hours when the temperature reached 97° C., and cooled after the reaction was complete. Suction filter the reactant cooled to room temperature, wash with distilled water and absolute ethanol in sequence, and finally put it into a constant temperature drying oven, keep the temperature at 110°C and dry for 3 hours to obtain spherical hydroxyapatite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com