Treatment method and device for pharmaceutical wastewater

A pharmaceutical wastewater and treatment method technology, applied in the field of water treatment, can solve the problems of complex operation, high treatment cost, high operating cost, etc., and achieve the effects of stable flux, high retention rate and high color value removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

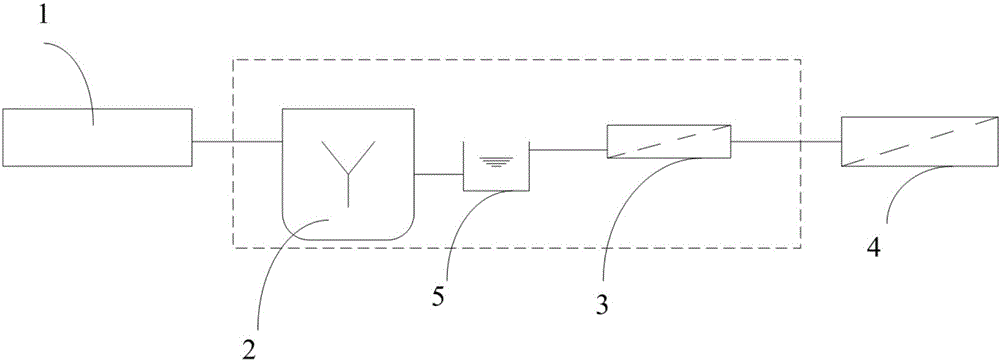

Image

Examples

Embodiment 1

[0058] In this example, the wastewater produced in the synthetic antibiotic workshop is treated. Its main components are amide compounds, isopropyl ether, chloroform, etc. The color of the wastewater is orange-red, there are many types of organic pollutants, and the biodegradability is poor. BOD 5 / COD Cr The value is small, the specific conditions of the effluent water quality are: conductivity 0.33s / cm, pH 9.27, dissolved oxygen 7.17mg / L, COD Cr 72000mg / L, BOD6.6mg / L, turbidity 158mg / L.

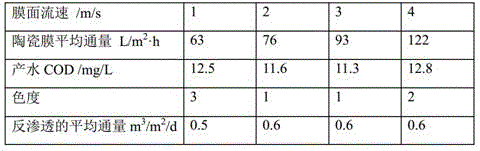

[0059] After the wastewater is treated in the primary sedimentation tank, it is treated by aerobic-anaerobic-aerobic biochemical system. The aerobic biochemical tank is operated under the following conditions: the inlet temperature is 30~32℃, the dissolved oxygen at the end of the contact oxidation tank is 2.5mg / L, the sludge concentration is 3000mg / L, the sludge sedimentation ratio is 30%, the mixed solution is refluxed 150%, and the reaction stays. The time is 10h; the anaerobic biochemical t...

Embodiment 2

[0063] In this example, the wastewater produced in the synthetic antibiotic workshop is treated. Its main components are amide compounds, isopropyl ether, chloroform, etc. The color of the wastewater is orange-red, there are many types of organic pollutants, and the biodegradability is poor. BOD 5 / COD Cr The value is small, the specific conditions of the effluent water quality are: conductivity 0.33s / cm, pH 9.27, dissolved oxygen 7.17mg / L, COD Cr 72000mg / L, BOD6.6mg / L, turbidity 158mg / L.

[0064] After the wastewater is treated in the primary sedimentation tank, it is treated by aerobic-anaerobic-aerobic biochemical system. The aerobic biochemical tank is operated under the following conditions: the inlet temperature is 30~32℃, the dissolved oxygen at the end of the contact oxidation tank is 2.5mg / L, the sludge concentration is 3000mg / L, the sludge sedimentation ratio is 30%, the mixed solution is refluxed 150%, and the reaction stays. The time is 10h; the anaerobic biochemical t...

Embodiment 3

[0069] The waste water produced in the Chinese patent medicine workshop is processed in this embodiment. The waste water is dark brown in color, has many kinds of organic pollutants, and has good biodegradability. BOD 5 / COD Cr The value is high, the specific conditions of the effluent water quality are: SS450mg / L, pH 6.6, COD Cr 4100mg / L, BOD1500mg / L, color 895.

[0070] After the wastewater is treated in the primary sedimentation tank, it is treated by an aerobic biochemical system. The aerobic biochemical tank is operated under the following conditions: the inlet temperature is 30~32℃, the dissolved oxygen at the end of the contact oxidation tank is 3mg / L, the sludge concentration is 10000mg / L, the sludge sedimentation ratio is 30%, the mixed solution is refluxed 150%, and the reaction residence time 8h; After treatment, the COD of the product water is 294.1mg / L, and the color is 100.

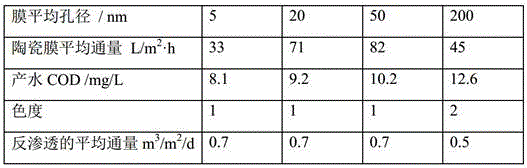

[0071] After the treated water is separated by solid-liquid in the secondary sedimentation ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com