Silica-supported bis-acid functionalized ionic liquid and its preparation method and application

A technology of ionic liquid and silica, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of less research on biomass hydrolysis, etc. Achieve the effect of overcoming difficulty in separation, low price and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

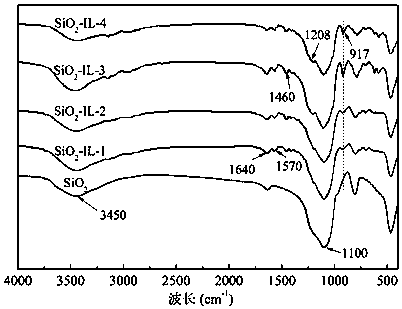

[0027] Embodiment 1 Preparation and characterization of catalyst

[0028] The preparation process is outlined as follows: under magnetic stirring at 110°C, add 2.78 g of imidazole to the flask, and after it melts into a liquid, add 9.5 mL of 3-chloropropyltriethoxysilane, N 2 Protect and continue to stir for 24h to obtain a clear viscous solution. After repeated washing with ether, spin evaporate to obtain N-(3-propyltriethoxysilane) imidazolium chloride salt; ethanol dissolves the above-mentioned ionic liquid (the molar ratio is 100:1 ), add 100-200 mesh silica (the molar ratio of silica to ionic liquid is 4:1), reflux with magnetic stirring at 85°C for 24h, wash with 10mL ethanol for 5 times, and dry at 100°C to obtain immobilized ion Liquid (SiO 2 / IL-1). The catalyst is characterized by TEM, FT-IR, TG, BET and elemental analysis, and it can be concluded that the ionic liquid is successfully bonded to silicon dioxide.

Embodiment 2

[0029] Example 2 Preparation and Characterization of Catalyst

[0030] The preparation process is outlined as follows: under magnetic stirring at 110°C, add 2.78 g of imidazole to the flask, and after it melts into a liquid, add 9.5 mL of 3-chloropropyltriethoxysilane, N 2 Protect and continue to stir for 24h to obtain a clear viscous solution. After repeated washing with ether, spin evaporate to obtain N-(3-propyltriethoxysilane) imidazole chloride salt; equimolar amounts of 1,4-butanesulfonate Acid lactone at 15°C, N 2 Slowly add dropwise to the ethanol solution of N-(3-propyltriethoxysilane)imidazolium chloride salt (the mass ratio of ionic liquid to ethanol is 1:3) under the atmosphere, N 2 Reaction at 45°C for 24 hours under the atmosphere, rotary evaporation, repeated washing with ether, and rotary evaporation to obtain a light yellow and clear ionic liquid 3-(4-sulfobutyl)-1-(3-propyltriethoxysilane)imidazole Chloride salt; Dissolve the above ionic liquid in ethanol (...

Embodiment 3

[0031] Preparation and characterization of embodiment 3 catalyst

[0032] The preparation process is outlined as follows: under magnetic stirring at 110°C, add 2.78 g of imidazole to the flask, and after it melts into a liquid, add 9.5 mL of 3-chloropropyltriethoxysilane, N 2 Protect and continue to stir for 24h to obtain a clear viscous solution. After repeated washing with ether, spin evaporate to obtain N-(3-propyltriethoxysilane) imidazolium chloride salt; ethanol dissolves the above-mentioned ionic liquid (the molar ratio is 100:1 ), add 100-200 mesh silica (the molar ratio of silica to ionic liquid is 4:1), reflux with magnetic stirring at 85°C for 24h, wash with 10mL ethanol for 5 times, and dry at 100°C to obtain immobilized ion Liquid: Weigh 1.4g of the above product and disperse it in 7mL of ethanol, add excess concentrated sulfuric acid (350mL) dropwise, stir and reflux with magnetic force at 80°C for 24h, wash with ethanol repeatedly until the filtrate is neutral, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com