A method for co-preparing ovalbumin and ovotransferrin

A technology of ovalbumin and ovotransferrin, which is applied in the field of co-preparation of ovalbumin and ovotransferrin, can solve the problems of desalination or small scale, limited separation scale, and the need for expensive equipment, and achieve short production cycle and easy large-scale Large-scale industrial production and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

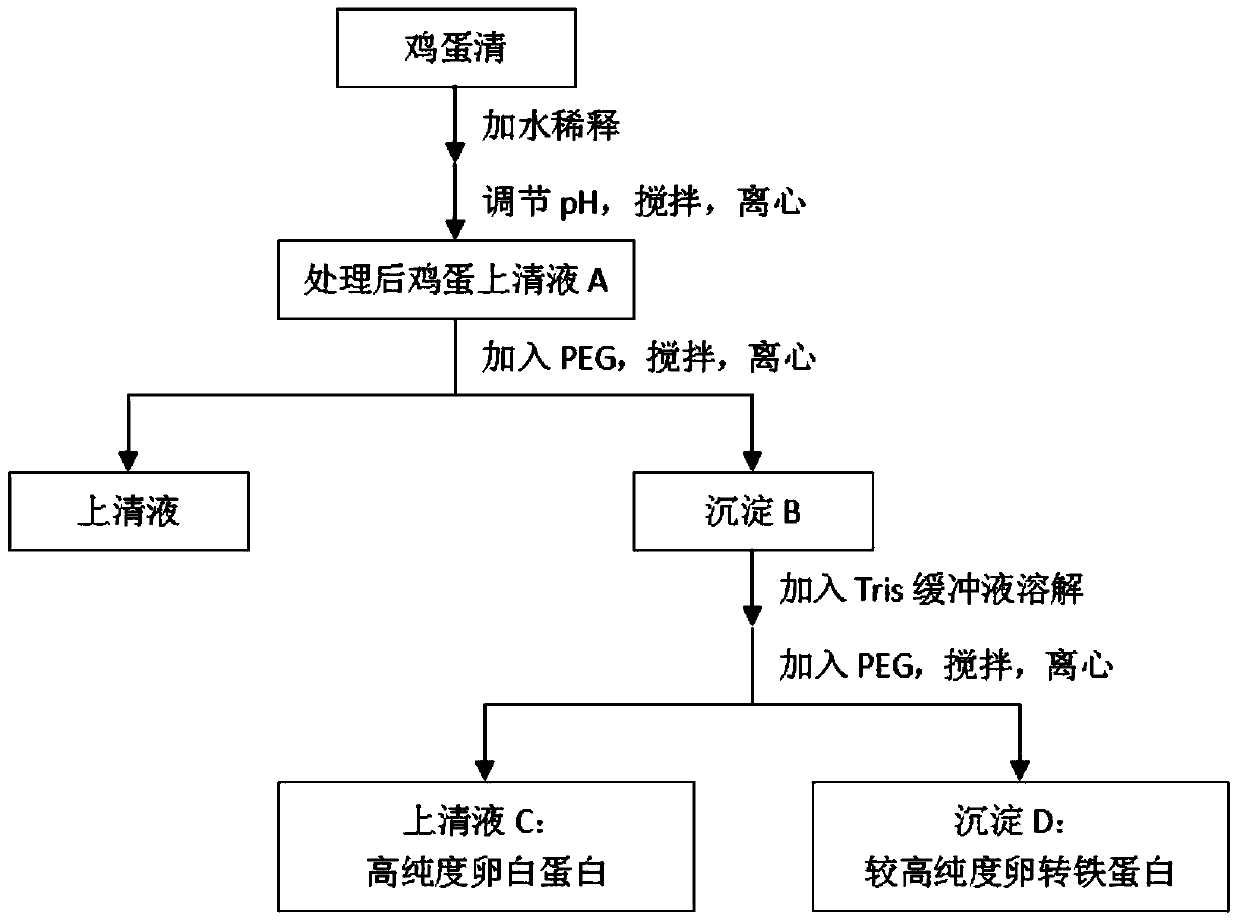

Image

Examples

Embodiment 1

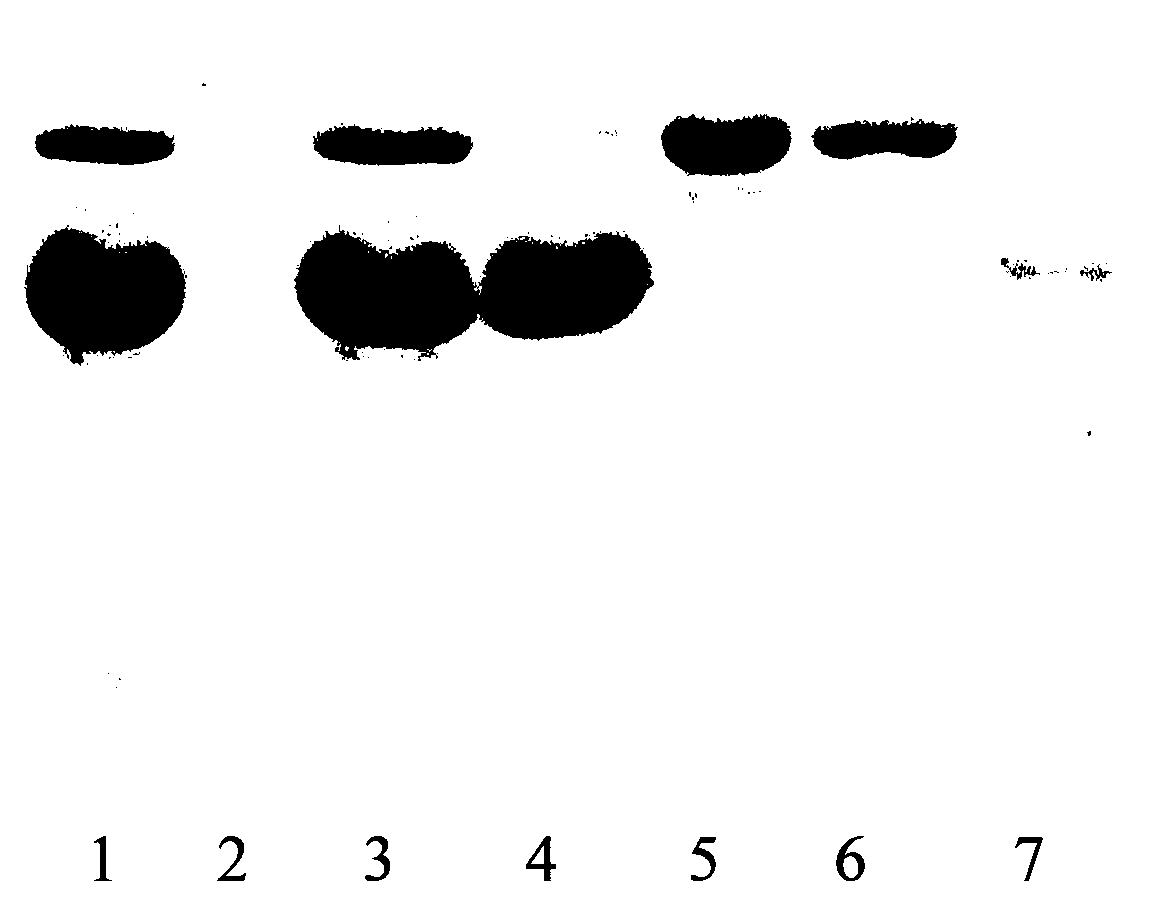

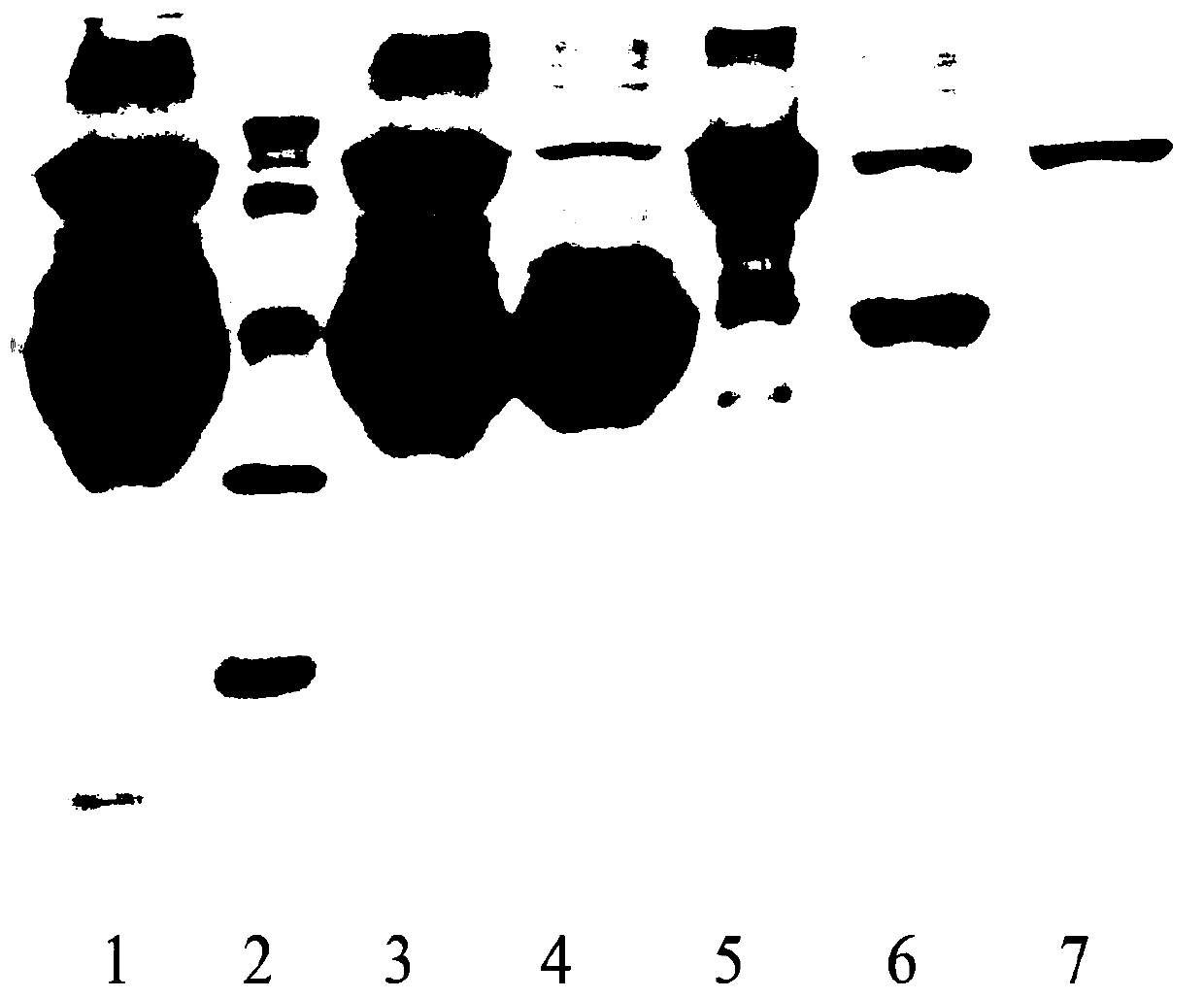

[0022] Take 100ml of fresh egg white, add 200ml of fresh deionized water, adjust the pH to about 5.0, stir evenly for 1 hour, and centrifuge at 8000 rpm for 30min to remove the precipitate. Add polyethylene glycol 20000 to the supernatant A obtained by centrifugation until its mass percentage concentration is 15%, stir for 1 hour, centrifuge at 8000rpm for 30min, collect the precipitate B, and dissolve it in 50ml 20mM Tris solution (pH8.0) The precipitate was stirred for 1 hour to fully dissolve the precipitate, then polyethylene glycol 200 solution was added to the resulting solution until its mass percentage concentration was 8%, stirred for another 1 hour, centrifuged at 8000rpm for 30min, and the supernatant C and precipitate D were collected . The obtained supernatant C was detected by sodium dodecylsulfonate-polyacrylamide gel electrophoresis and showed that it contained ovalbumin with a purity of 99.7%, and the total yield was 61.5%; the obtained precipitate D was subje...

Embodiment 2

[0025] Take 100ml of fresh egg white, add 200ml of fresh deionized water, adjust the pH to about 5.0, stir evenly for 1 hour, and centrifuge at 8000 rpm for 30min to remove the precipitate. Add polyethylene glycol 200 to the supernatant A obtained by centrifugation until its mass percentage concentration is 30%, stir for 1 hour, centrifuge at 8000rpm for 30min, collect the precipitate B, and dissolve it in 50ml 20mM Tris solution (pH8.0) The precipitate was stirred for 1 hour to fully dissolve the precipitate, then polyethylene glycol 200 solution was added to the resulting solution until its mass percentage concentration was 15%, stirred for another 1 hour, centrifuged at 8000rpm for 30min, and supernatant C and precipitate D were collected . The obtained supernatant C was detected by sodium dodecylsulfonate-polyacrylamide gel electrophoresis and showed that it contained ovalbumin with a purity of 91.6%, and the total yield was 72.3%; the obtained precipitate D was subjected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com