Low-expansion high-thermal-conducting copper-stainless invar alloy composite material and preparation method thereof

A composite material, stainless steel technology, applied in metal processing equipment, coating, transportation and packaging, etc., to achieve the effect of reducing production cost, easy sintering, and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

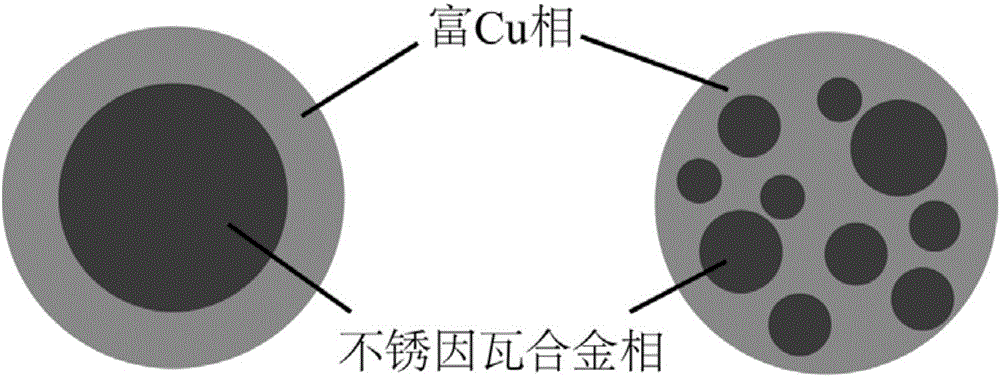

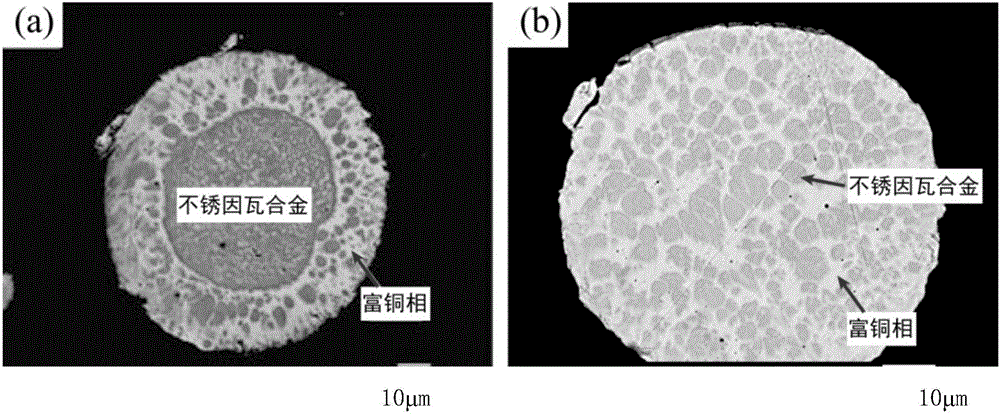

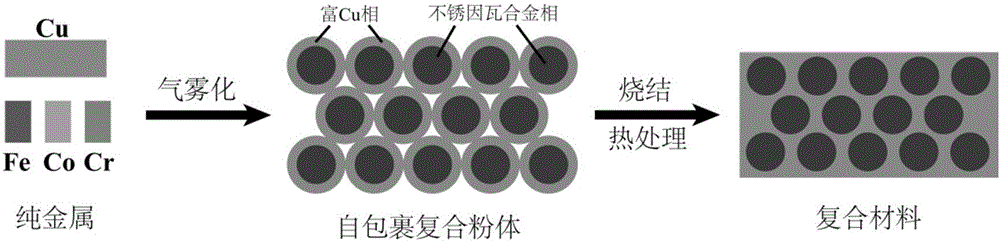

Method used

Image

Examples

Embodiment 1

[0040] Using high-purity metals Cu, Fe, Co, and Cr as raw materials, it is configured according to Cu700g, Fe110g, Co160g, and Cr30g. The error in the actual configuration process is guaranteed to be within 0.001g. First, the weighed alloy raw materials are ultrasonically cleaned, and then placed in the vacuum induction furnace of the atomization equipment. Pump the chamber of the atomization device to 1×10 -3 The vacuum degree of Pa is filled with argon to slightly more than 1 atmospheric pressure. After the alloy is completely melted into a liquid, the air pressure device is started to make the molten liquid flow into the atomization chamber, and at the same time, the high-pressure argon valve (air pressure is 3-10MPa) is quickly opened to spray high pressure. The gas atomizes the metal liquid. When all the molten liquid flows into the spray chamber, the argon flow valve can be closed. After the atomization equipment cools down, powder samples can be obtained in the collec...

Embodiment 2

[0043] Using high-purity metals Cu, Fe, Co, and Cr as raw materials, it is configured according to Cu400g, Fe220g, Co320g, and Cr60g. The error in the actual configuration process is guaranteed to be within 0.001g. First, the weighed alloy raw materials are ultrasonically cleaned, and then placed in the vacuum induction furnace of the atomization equipment. Pump the chamber of the atomization device to 1×10 -3 The vacuum degree of Pa is filled with argon to slightly more than 1 atmospheric pressure. After the alloy is completely melted into a liquid, the air pressure device is started to make the molten liquid flow into the atomization chamber, and at the same time, the high-pressure argon valve (air pressure is 3-10MPa) is quickly opened to spray high pressure. The gas atomizes the metal liquid. When all the molten liquid flows into the spray chamber, the argon flow valve can be closed. After the atomization equipment cools down, powder samples can be obtained in the collec...

Embodiment 3

[0046] Using high-purity metals Cu, Fe, Co, and Cr as raw materials, it is configured according to Cu250g, Fe280g, Co400g, and Cr70g. The error in the actual configuration process is guaranteed to be within 0.001g. First, the weighed alloy raw materials are ultrasonically cleaned, and then placed in the vacuum induction furnace of the atomization equipment. Pump the chamber of the atomization device to 1×10 -3 The vacuum degree of Pa is filled with argon to slightly more than 1 atmospheric pressure. After the alloy is completely melted into a liquid, the air pressure device is started to make the molten liquid flow into the atomization chamber, and at the same time, the high-pressure argon valve (air pressure is 3-10MPa) is quickly opened to spray high pressure. The gas atomizes the metal liquid. When all the molten liquid flows into the spray chamber, the argon flow valve can be closed. After the atomization equipment cools down, powder samples can be obtained in the collec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com