Neodymium-iron-boron permanent magnet surface protection method

A neodymium iron boron, surface treatment technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem of target poisoning, affecting the effect of aluminum plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

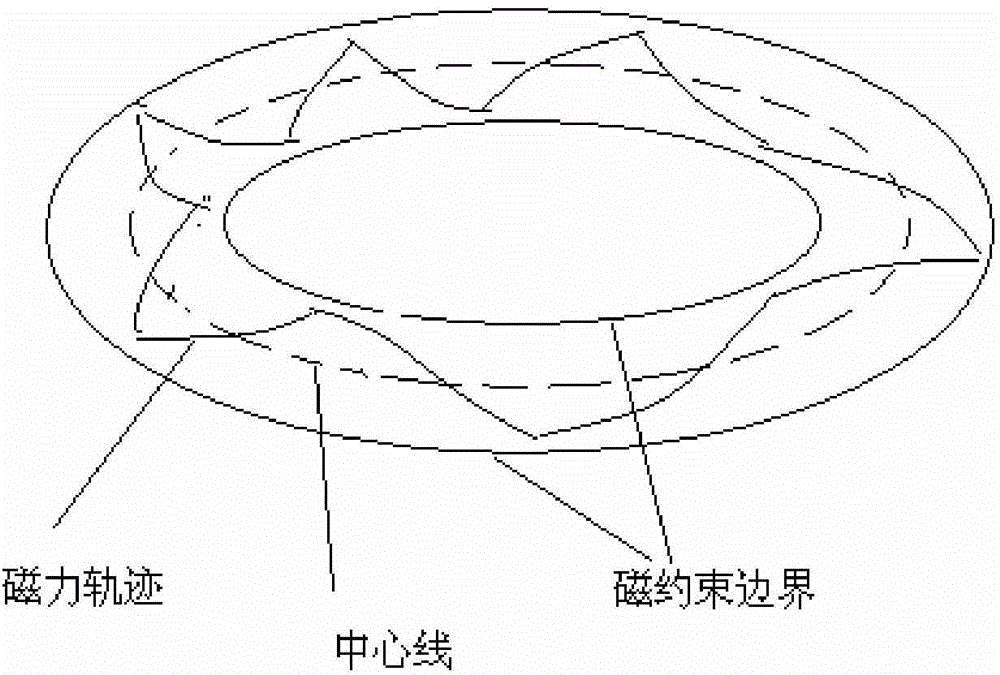

Method used

Image

Examples

Embodiment 1

[0018] First put the 2.5kg The sintered NdFeB permanent magnet material was mechanically vibrated in a vibration mill for 2 hours, then degreased and degreased with an alkaline solution (sodium phosphate 20g / L, sodium carbonate 10g / L and sodium hydroxide 10g / L), and then in Pickling and rust removal in 1% nitric acid solution. Then wet sandblasting to remove rust.

[0019] Hang the dried NdFeB workpiece in the vacuum chamber, vacuumize to 10Pa with a mechanical pump, and then vacuumize with a turbomolecular pump to make the vacuum of the vacuum chamber reach 1.0*10 -4 Pa. Using argon as the working gas, fill it with argon to 25 Pa, use a DC power supply with a negative bias of 400 volts, and a temperature of 250 degrees to magnetron sputter aluminum in a vacuum sintering furnace. The aluminum plating time is 160 minutes, and the thickness of the aluminum layer is 1.2 microns. Oxygen is introduced, the ratio of oxygen and argon is 1:5, the vacuum degree in the room is 5 Pa...

Embodiment 2

[0021] According to the method of embodiment 1 to 2.5kg NdFeB permanent magnet materials for surface pretreatment. Then wet sandblasting to remove rust. Hang the dried NdFeB workpiece in the vacuum chamber, vacuumize to 10Pa with a mechanical pump, and then vacuumize with a turbomolecular pump to make the vacuum of the vacuum chamber reach 1.0*10 -3 Pa. Using argon as the working gas, fill it with argon to 15 Pa, use a DC power supply with a negative bias of 450 volts, and a temperature of 250 degrees to magnetron sputter aluminum in a vacuum sintering furnace. The aluminum plating time is 200 minutes, and the thickness of the aluminum layer is 3 microns. Oxygen is introduced, the ratio of oxygen and argon is 1:4, the vacuum degree in the room is 5 Pa, the radio frequency power supply is 600 volts negative bias, the temperature is 230 degrees, and the aluminum oxide is plated by magnetron sputtering, and the thickness of the aluminum layer is 2 microns. See Table 1.

Embodiment 3

[0023] According to the method of embodiment 1 to 2.5kg NdFeB permanent magnet materials for surface pretreatment. Then wet sandblasting to remove rust. Hang the dried NdFeB workpiece in the vacuum chamber, vacuumize to 10Pa with a mechanical pump, and then vacuumize with a turbomolecular pump to make the vacuum of the vacuum chamber reach 1.0*10 -4 Pa. Using argon as the working gas, fill it with argon to 25 Pa, use a DC power supply with a negative bias of 400 volts, and a temperature of 250 degrees to magnetron sputter aluminum in a vacuum sintering furnace. The aluminum plating time is 300 minutes, and the thickness of the aluminum layer is 1.0 micron. Oxygen is introduced, the ratio of oxygen and argon is 1:4.5, the vacuum degree in the room is 5 Pa, the negative bias of 600 volts of radio frequency power is used, the temperature is 230 degrees, and the aluminum oxide is plated by magnetron sputtering, and the thickness of the aluminum layer is 3 microns. See Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com