A preparation method of low-temperature ohmic contact on gan HEMT

A technology of ohmic contact and low temperature, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of poor surface morphology of ohmic contact metals, achieve improved flatness and edge quality, large process tolerance, The effect of improving the flatness and edge quality of ohmic metal surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

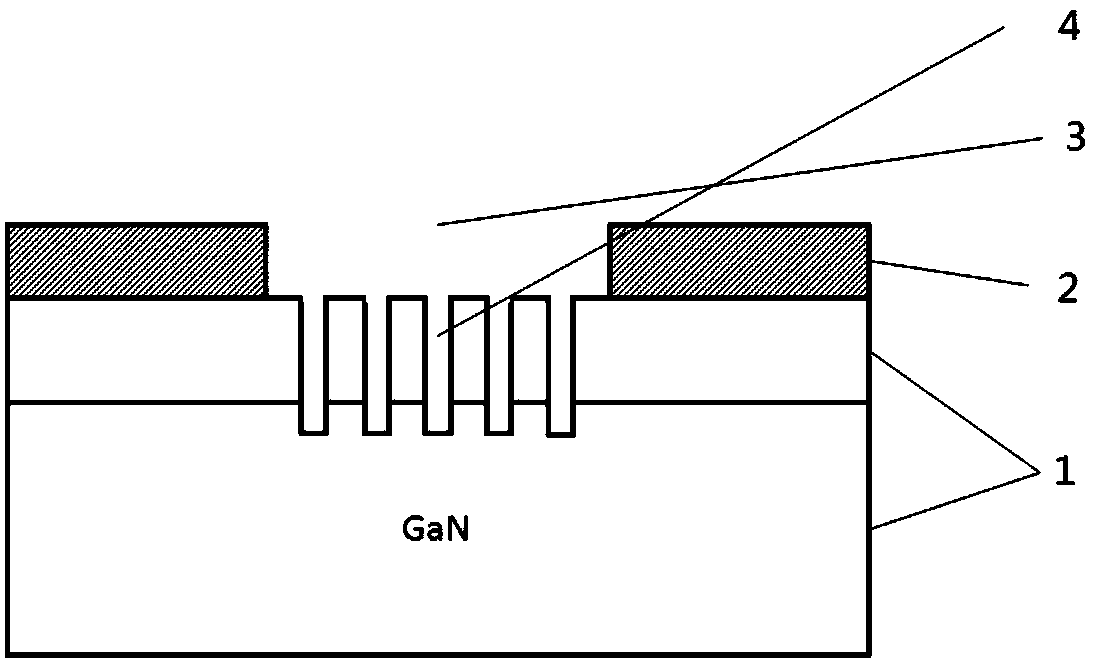

[0034] The technical solution of the present invention will be further described below in conjunction with the drawings;

[0035] The invention is a method for reducing the ohmic contact annealing temperature of a GaN HEMT device based on etching and diffusion technology, which includes growing a dielectric layer; making an ohmic contact window; making an ohmic contact through hole; making a diffusion layer; growing a dielectric layer; diffusing; and etching Dielectric layer; making ohmic contact metal. The specific method is as follows"

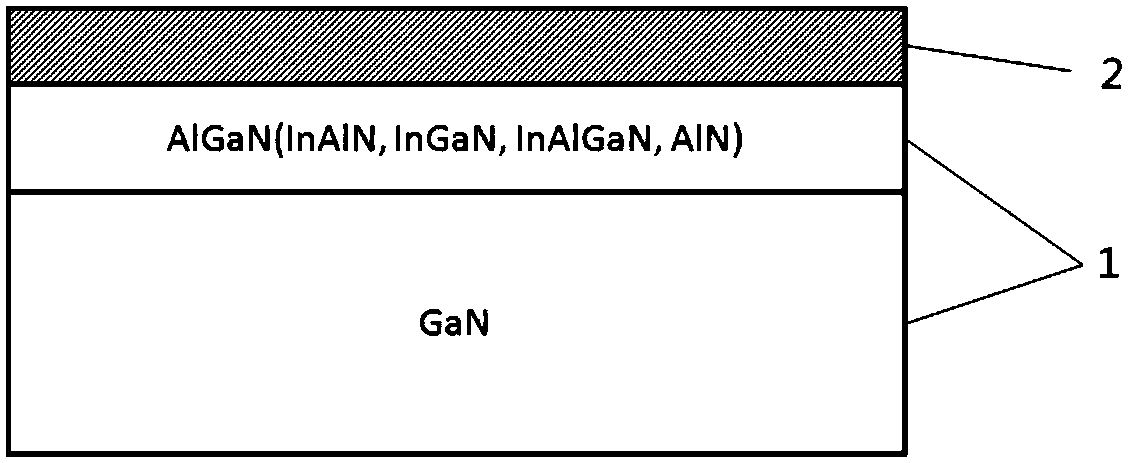

[0036] (1) Using ALD to grow Al with a thickness of 50nm on AlGaN / GaN heterojunction material 1 2 O 3 Medium 2, such as figure 1 Shown. In step (1), the first dielectric layer 2 is prepared by a deposition process, and the first dielectric layer 2 is (Al 2 O 3 ), aluminum nitride (AlN), the deposition method is sputtering, atomic layer deposition, and the dielectric thickness is 50-100nm

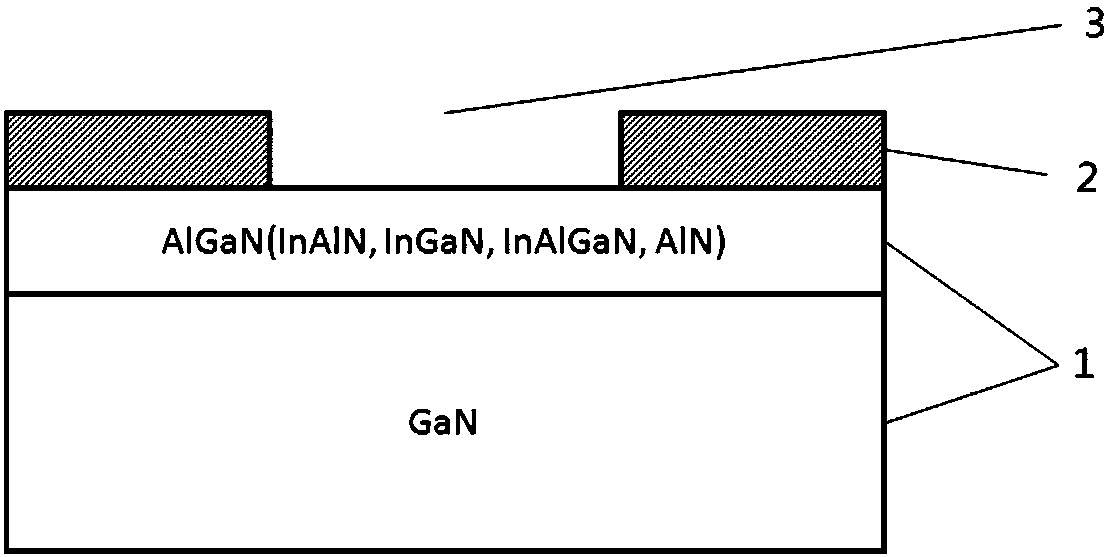

[0037] (2) In Al 2 O 3 The ohmic contact window 3 is prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com