Hydrating silk mask and preparation method thereof

The technology of facial mask and silk is applied in the field of moisturizing silk facial mask and its preparation, which can solve the problems of many chemical components and harm, and achieve the effect of moisturizing the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

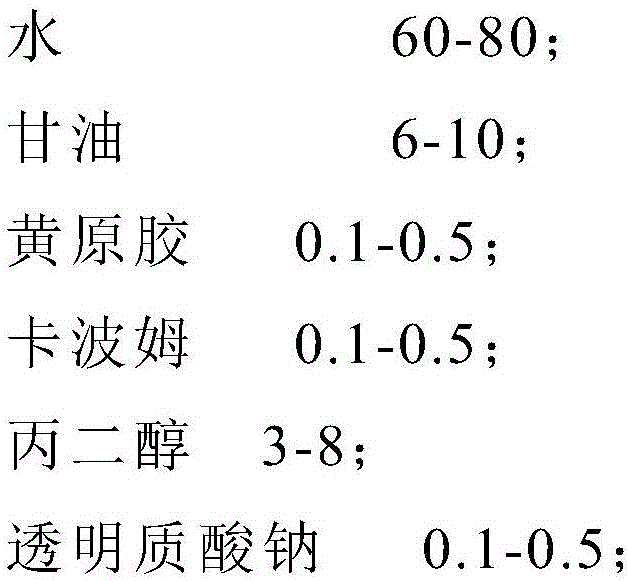

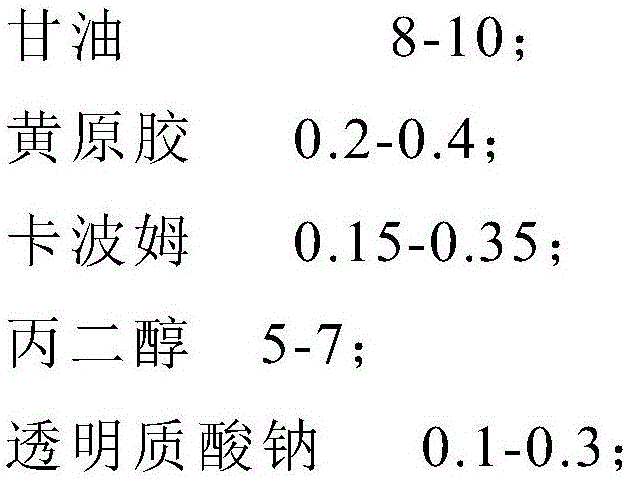

Method used

Image

Examples

Embodiment 1

[0049] Add 68wt% water and 9wt% glycerin into the emulsification pot, start stirring, the stirring speed is 20-25 rpm, turn on the steam, heat to 90°C; stop stirring, add 0.2wt% carbomer, homogenize at high speed for 2 minutes , so that the material is dispersed evenly until there are no particles; vacuumize and heat-preserve at about 80°C to defoam; mix 0.2wt% xanthan gum, 5wt% propylene glycol and 0.2wt% sodium hyaluronate until there are no particles, add it to the emulsification pot, and stir After 2 minutes, homogenize at high speed and keep vacuum defoaming;

[0050] After defoaming, when the temperature drops to 60°C, add 0.1wt% triethanolamine, turn on the cooling water switch, and start to cool down; then add 3.3wt% glycerol polymethacrylate, 3.5wt% 1,2-pentanediol, 0.2 Wt% caprylyl glycol, 0.06wt% PEG-40 castor oil and 7wt% rose extract, stir and mix evenly;

[0051] When the temperature is lowered to 45°C, add 3wt% Hamamelis hamamelis extract and 0.24wt% aloe vera ...

Embodiment 2

[0053] Add 71wt% water and 8wt% glycerin into the emulsification pot, start stirring, the stirring speed is 20-25 rpm, turn on the steam, heat to 90°C; stop stirring, add 0.15wt% carbomer, and homogenize at high speed for 2 minutes , so that the material is dispersed evenly until there are no particles; vacuumize and heat-preserve at about 80°C to defoam; mix 0.3wt% xanthan gum, 6.5wt% propylene glycol and 0.25wt% sodium hyaluronate until there are no particles, then add it to the emulsification pot, After stirring for 2 minutes, homogenize at high speed and keep vacuum defoaming;

[0054] After defoaming, when the temperature drops to 60°C, add 0.3wt% triethanolamine, turn on the cooling water switch, and start to cool down; then add 4wt% glycerol polymethacrylate, 4.5wt% 1,2-pentanediol, 0.3wt% % octane glycol, 0.05wt% PEG-40 castor oil and 7.4wt% rose flower extract, stir and mix evenly;

[0055] When the temperature is lowered to 45°C, add 4wt% Hamamelis hamamelis extract...

Embodiment 3

[0057] Add 66wt% water and 8.5wt% glycerin into the emulsification pot, start stirring, the stirring speed is 20-25 rpm, turn on the steam, heat to 90°C; stop stirring, add 0.3wt% carbomer, high-speed homogenization 2 Minutes to disperse the material evenly until there are no particles; evacuate and heat at about 80°C to defoam; mix 0.3wt% xanthan gum, 6wt% propylene glycol and 0.1wt% sodium hyaluronate until there are no particles, then add it to the emulsification pot, After stirring for 2 minutes, homogenize at high speed and keep vacuum defoaming;

[0058] After defoaming, when the temperature is lowered to 60°C, add 0.25wt% triethanolamine, turn on the cooling water switch, and start to cool down; then add 5wt% glycerol polymethacrylate, 3wt% 1,2-pentanediol, 0.3wt% Caprylyl glycol, 0.06wt% PEG-40 castor oil and 7wt% rose extract, stirred and mixed evenly;

[0059] When the temperature is lowered to 45°C, add 3.05wt% North American witch hazel extract and 0.14wt% aloe ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com