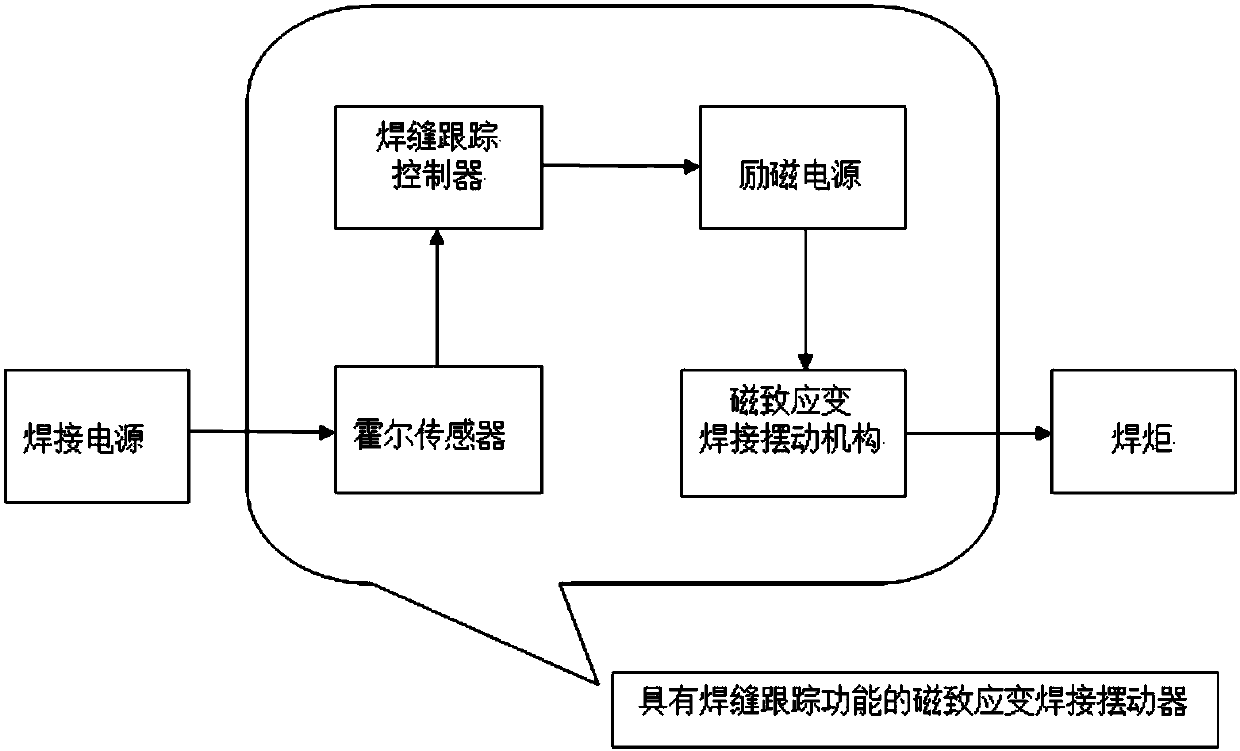

A Magnetic Strain Welding Oscillator with Seam Tracking Function

A technology with magneto-induced strain and tracking function, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor real-time and controllability, large mechanical wear, short service life, etc., to ensure accuracy and stability , The effect of small mechanical wear and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

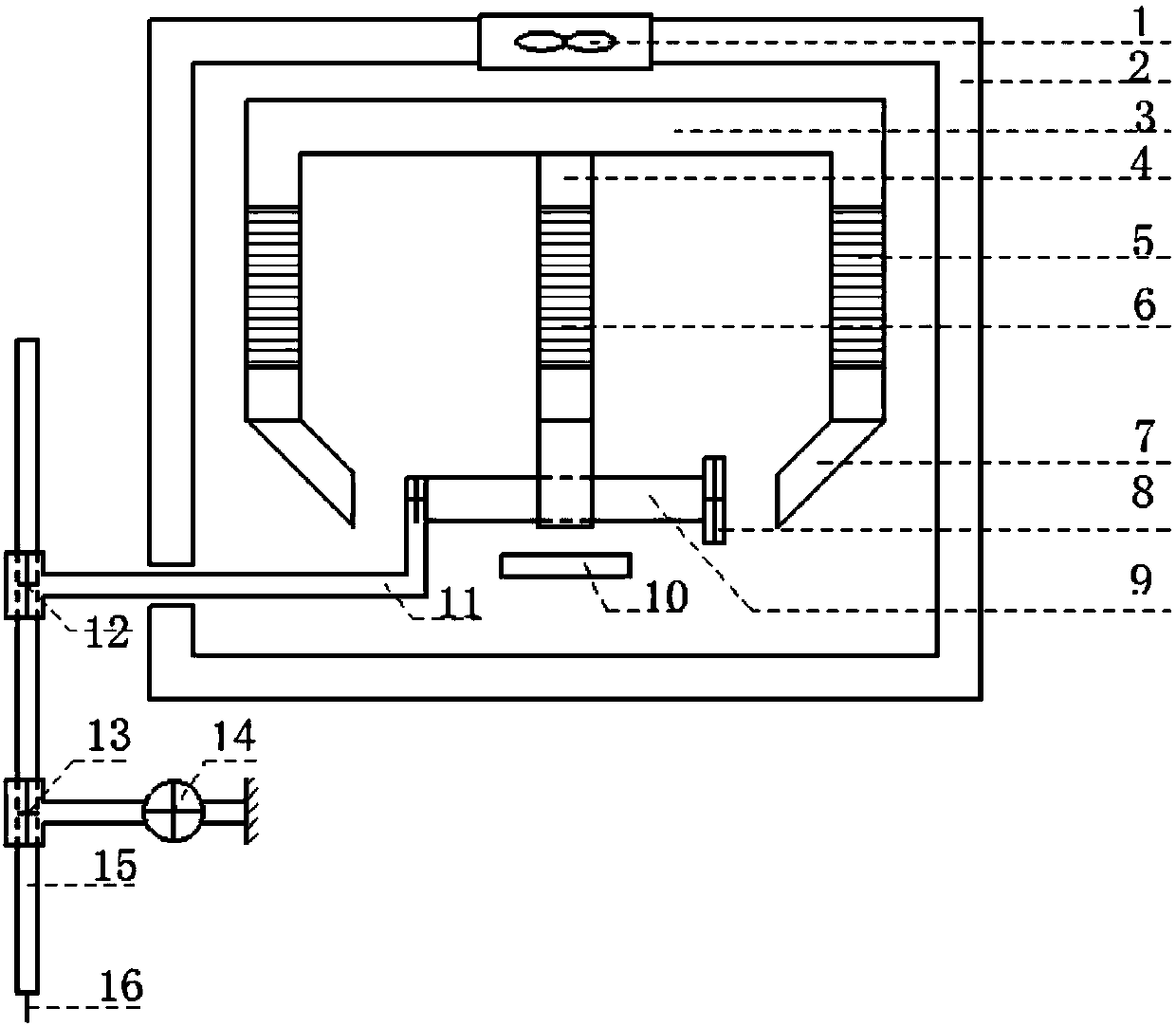

Embodiment 1

[0022] Embodiment 1, choose NiMnGa series single crystal shape memory alloy, make L 0 *L 0 *L 1The cuboid magnetically controlled shape memory alloy guide rod (9), the right end of the magnetically controlled shape memory alloy guide rod (9) is fixed on the right magnetic pole (7) of the No. 1 U-shaped magnetic core (3) through the fixed valve (8), ensuring that the magnetic The right end surface of the control shape memory alloy guide rod (9) is relatively parallel to the plane of the right magnetic pole (7) of the No. 1 U-shaped magnetic core (3), so that the magnetic control shape memory alloy guide rod (9) is perpendicular to the longitudinal magnetic field lines, and the magnetic The left end of the control shape memory alloy guide rod (9) is fixedly connected with the right end of the non-ferromagnetic push rod (11), and the excitation power supply generates an excitation current according to the control parameters of the seam tracking controller, and the excitation cur...

Embodiment 2

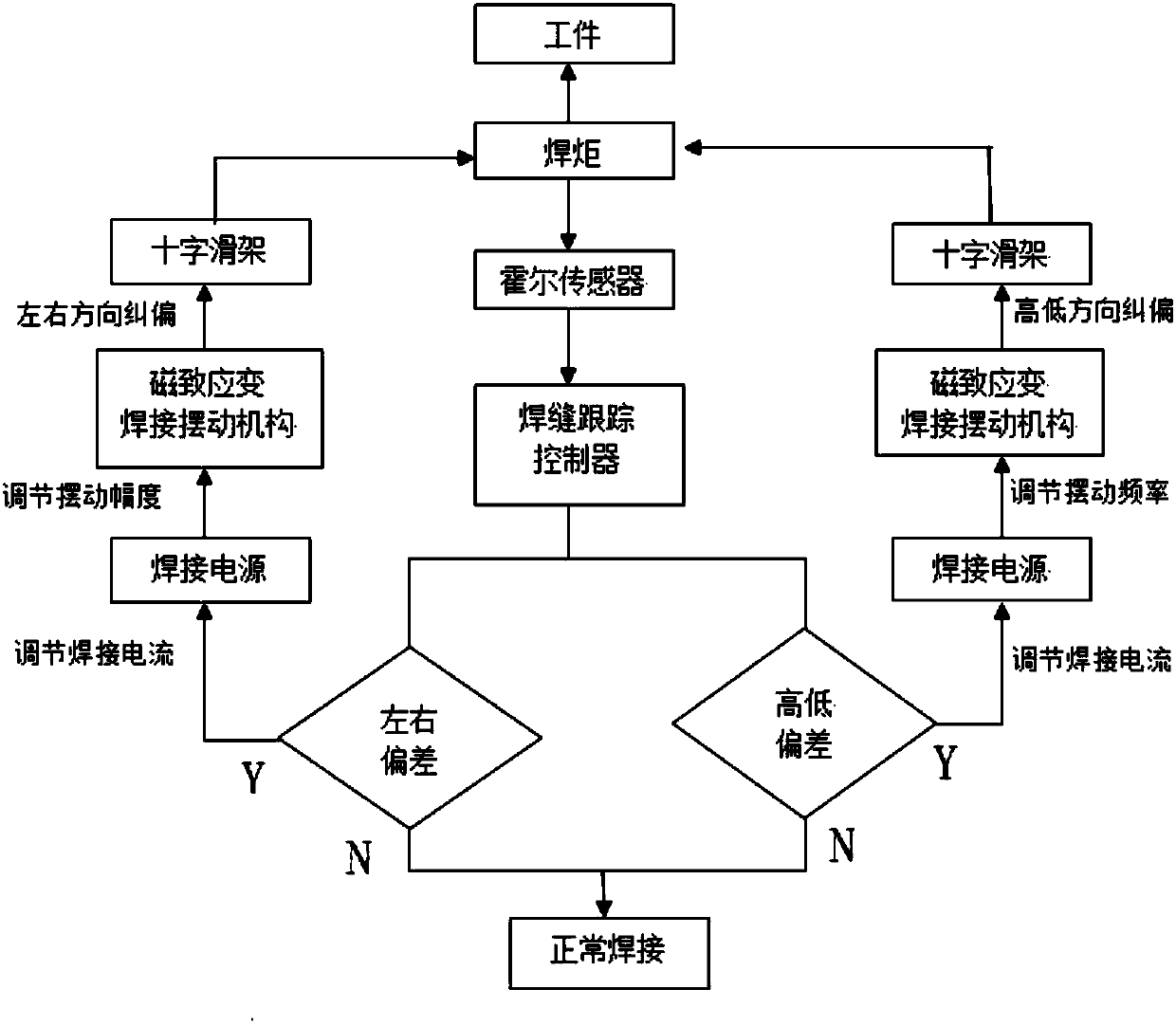

[0035] Embodiment 2, in welding process, as image 3 , the current signal of the arc collected by the Hall sensor is filtered and amplified, and then sent to the seam tracking controller. The seam tracking controller processes and calculates it, and compares the collected current signal with the given current signal. , to determine whether there is a deviation between the welding torch and the welding seam; when there is a deviation in the left and right direction between the welding torch and the welding seam, increase the welding current, and at the same time increase the longitudinal excitation current by controlling the excitation power supply, so that the swing amplitude of the magneto-induced strain welding swing mechanism Increase, the width of weld deposition increases to ensure the depth of weld penetration, and the cross carriage moves synchronously to adjust left and right to keep the welding torch in a centered state; when the welding torch is relatively high relati...

Embodiment 3

[0036] In embodiment 3, the martensitic transformation temperature of NiMnGa series single crystal shape memory alloy is selected as 31°C, and the optimum working temperature range is 20-40°C. When the temperature detected by the real-time temperature detector is lower than 31°C, the weld seam tracking controller does not work according to the temperature parameter fed back; when the temperature detected by the real-time temperature detector is 31-40°C, the weld seam tracking The controller adaptively adjusts the power of the radiator according to the feedback temperature parameters to ensure that the magnetically controlled shape memory alloy guide rod works near the martensitic transformation temperature (31°C); when the temperature detected by the real-time temperature detector is higher than 40°C ℃, according to the temperature parameter fed back by the seam tracking controller, because the magnetic strain of the magnetic control shape memory alloy is no longer proportional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com