Electrosparking and mechanical processing Si3N4-ZrSi2-BN composite ceramic material and preparation method

A technology for machining and multiphase ceramics is applied in the field of Si3N4-ZrSi2-BN multiphase ceramic materials and preparation, and achieves the effects of uniform microstructure, simple preparation process and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

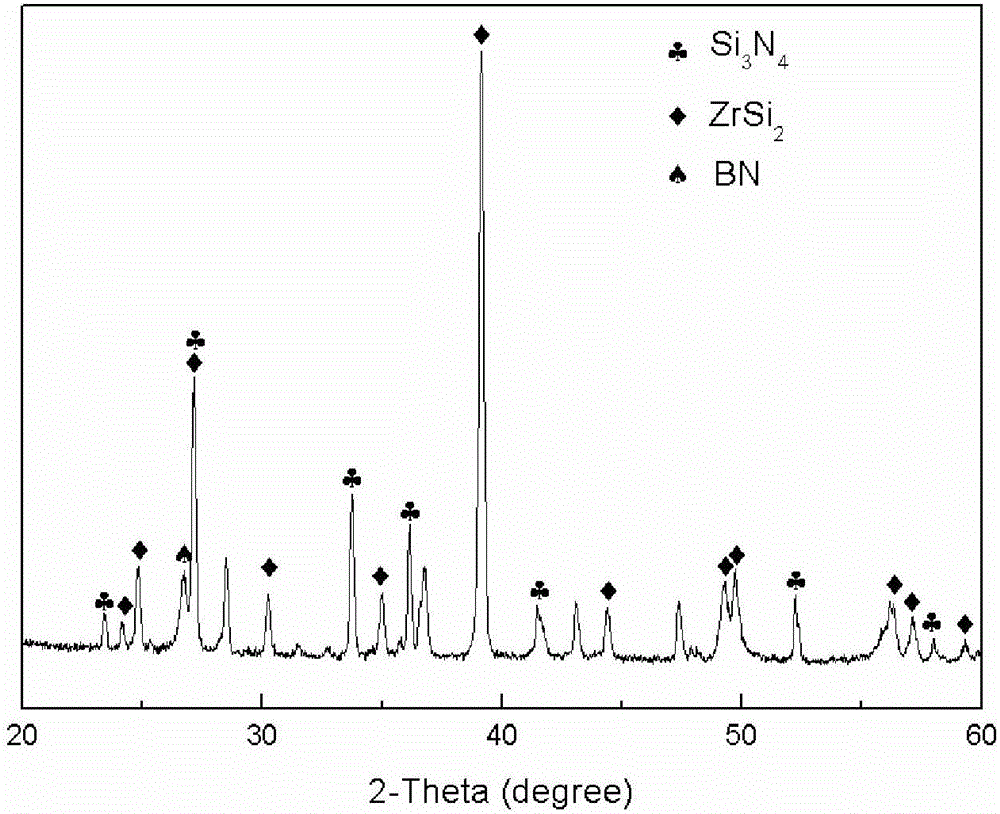

Image

Examples

Embodiment 1

[0027] Si 3 N 4 -ZrSi 2 -The preparation of BN composite phase ceramics, the specific method is as follows:

[0028] (1) with Si 3 N 4 powder (96% purity, particle size 2 (purity is 99%, particle size is 40nm) and boron (purity is 99%, particle size is 2 o 3 Auxiliaries are compounded, wherein the mass fraction ratio of raw materials and auxiliaries is 95% and 5%, Si 3 N 4 , ZrB 2 And the mass fraction ratio of B is 70.4%, 27.8% and 1.8%, MgO and Y 2 o 3The mass fraction ratio is 50% and 50%, with ethanol as solvent and Si 3 N 4 The ball is the ball milling medium, mixed on the roller ball mill for 24 hours, after mixing and drying, the MgO-Y 2 o 3 Auxiliary Si 3 N 4 -ZrB 2 -B mixed powder.

[0029] (2) Will contain MgO-Y 2 o 3 Auxiliary Si 3 N 4 -ZrB 2 -B mixed powder is put into the graphite mold that inner wall surface is coated with BN, carries out reaction hot pressing sintering according to two-step heat preservation method, and described two-step he...

Embodiment 2

[0032] (1) with Si 3 N 4 powder (96% purity, particle size 2 (purity is 99%, particle size is 40nm) and boron (purity is 99%, particle size is 2 o 3 Additives are compounded, wherein the mass fraction ratio of raw materials and additives is 90% and 10%, Si 3 N 4 , ZrB 2 And the mass fraction ratio of B is 70.4%, 27.8% and 1.8%, MgO and Y 2 o 3 The mass fraction ratio is 50% and 50%, with ethanol as solvent and Si 3 N 4 The ball is the ball milling medium, mixed on the roller ball mill for 24 hours, after mixing and drying, the MgO-Y 2 o 3 Auxiliary Si 3 N 4 -ZrB 2 -B mixed powder.

[0033] (2) Will contain MgO-Y 2 o 3 Auxiliary Si 3 N 4 -ZrB 2 -B mixed powder is put into the graphite mold that inner wall surface is coated with BN, carries out reaction hot pressing sintering according to two-step heat preservation method, and described two-step heat preservation method comprises: will contain MgO-Y 2 o 3 Auxiliary Si 3 N 4 -ZrB 2 -B The temperature of the ...

Embodiment 3

[0036] The mass fraction ratio of raw materials and additives is 95% and 5%, Si 3 N 4 , ZrB 2 And the mass fraction ratio of B is 83%, 16% and 1%, MgO and Y 2 o 3 The mass fraction ratio is 50% and 50%, and Si is prepared according to the method of Example 1 3 N 4 -ZrSi 2 -BN composite phase ceramics, wherein, the batching roller ball mill is mixed for 24 hours; wherein, the two-step heat preservation method is specifically: the first step, the heating rate is 20°C / min, the temperature rises to 1600°C, and the heat preservation is 2h; the second step, The heating rate was 10°C / min, filled with nitrogen and heated up to 1750°C, while applying a pressure of 30MPa, keeping the pressure for 1h, and obtained Si that can be processed by EDM and machining. 3 N 4 -ZrSi 2 -BN composite ceramic material. The relative density of the prepared ceramic material is 98%, the hardness of the material is 8GPa, and the fracture toughness is 5MPa m 1 / 2 , The bending strength is 450MPa. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com