Synthesis technology of 1-bromine 2,2-polyvinylidene floride

A technology for the synthesis of ethylene difluoride, which is applied in the field of 1-bromine 2, can solve the problems of difficult industrial scale implementation, high cost, and difficult acquisition of raw materials, and achieve the effects of easy industrial production, low cost, and easy availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

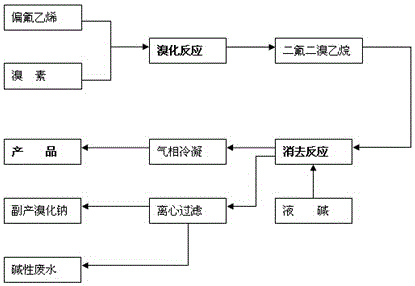

[0024] like figure 1 Shown, a kind of 1-bromo 2, the synthetic technique of 2-difluoroethylene, comprises the steps:

[0025] The first step, bromination reaction: use vinylidene fluoride as raw material and bromine for bromination addition reaction to generate dibromodifluoroethane; adopt batch process, bromine is metered and then sucked into the bromination reaction kettle by vacuum. Stirring was started, vinylidene fluoride gas was slowly introduced, and the temperature of the kettle was kept at 10°C. After 3 hours of reaction, the reaction was completed.

[0026] The second step, elimination reaction: the dibromodifluoroethane generated above is irradiated by infrared light in the presence of a catalyst, and alkali is added to eliminate hydrogen bromide to generate 1-bromo-2,2-difluoroethylene; Process, the product of the first step is measured and pumped into the reaction kettle, an appropriate amount of catalyst is added, stirring is started, and 10% lye is slowly added...

specific Embodiment 2

[0030] like figure 1 Shown, a kind of 1-bromo 2, the synthetic technique of 2-difluoroethylene, comprises the steps:

[0031] The first step, bromination reaction: use vinylidene fluoride as raw material and bromine for bromination addition reaction to generate dibromodifluoroethane; adopt batch process, bromine is metered and then sucked into the bromination reaction kettle by vacuum. Stirring was started, vinylidene fluoride gas was slowly introduced, and the temperature of the kettle was kept at 80°C. After 12 hours of reaction, the reaction was completed.

[0032] The second step, elimination reaction: the dibromodifluoroethane generated above is irradiated by infrared light in the presence of a catalyst, and alkali is added to eliminate hydrogen bromide to generate 1-bromo-2,2-difluoroethylene; The first step product is measured and pumped into the reaction kettle, an appropriate amount of catalyst is added, stirring is started, and 40% lye is slowly added dropwise, and ...

specific Embodiment 3

[0036] like figure 1 Shown, a kind of 1-bromo 2, the synthetic technique of 2-difluoroethylene, comprises the steps:

[0037] The first step, bromination reaction: use vinylidene fluoride as raw material and bromine for bromination addition reaction to generate dibromodifluoroethane; adopt batch process, bromine is metered and then sucked into the bromination reaction kettle by vacuum. Stirring was started, and vinylidene fluoride gas was slowly introduced, and the temperature of the kettle was kept at 60° C. After 8 hours of reaction, the reaction was completed.

[0038] The second step, elimination reaction: the dibromodifluoroethane generated above is irradiated by infrared light in the presence of a catalyst, and alkali is added to eliminate hydrogen bromide to generate 1-bromo-2,2-difluoroethylene; Process, the first step product is measured and pumped into the reaction kettle, an appropriate amount of catalyst is added, stirring is started, 30% lye is slowly added dropw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com