A kind of polyenamine compound and preparation method thereof

A compound, polyenamine technology, applied in the field of polymer chemistry and materials science, to achieve the effects of mild polymerization conditions, excellent regioselectivity, and high polymerization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

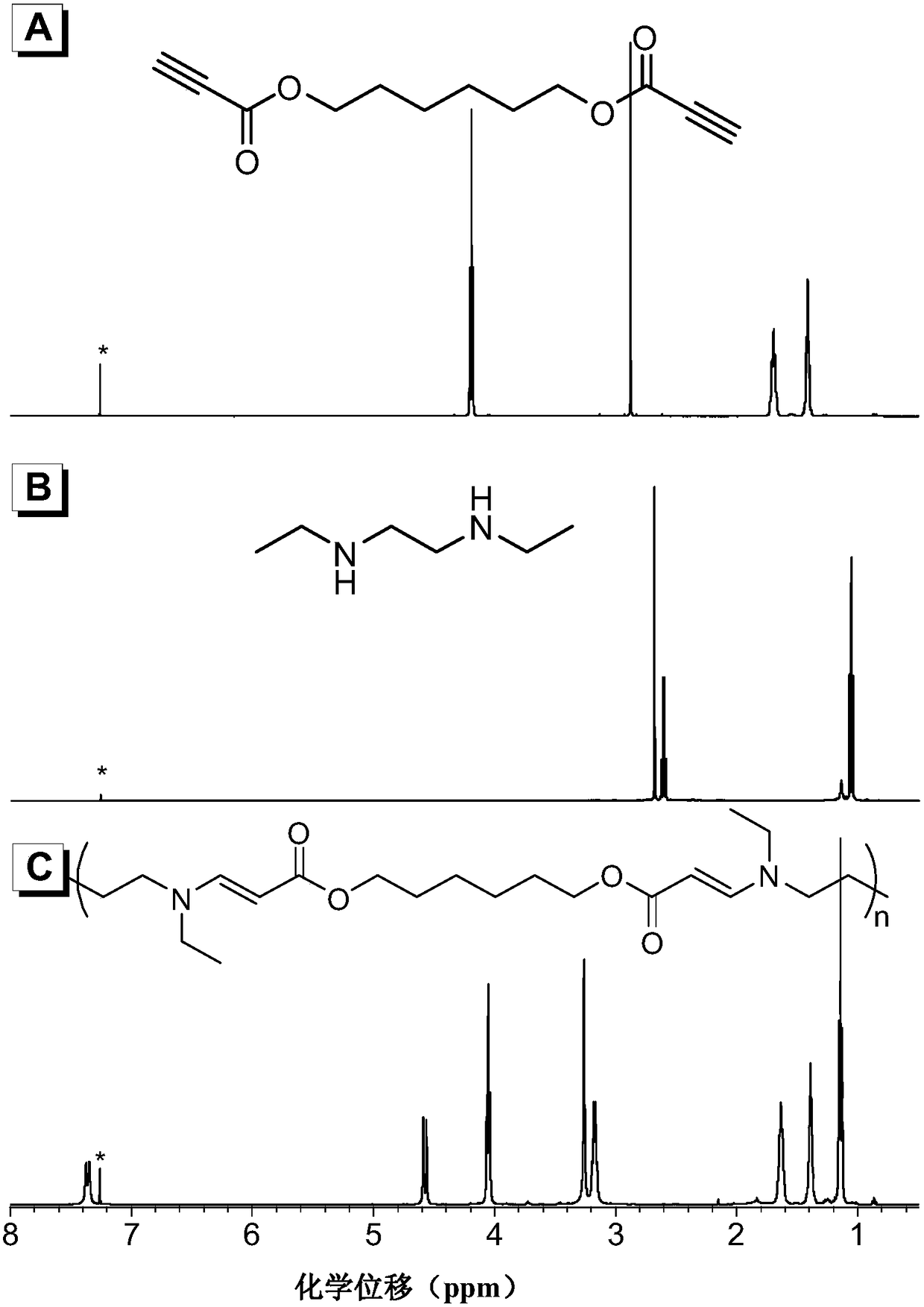

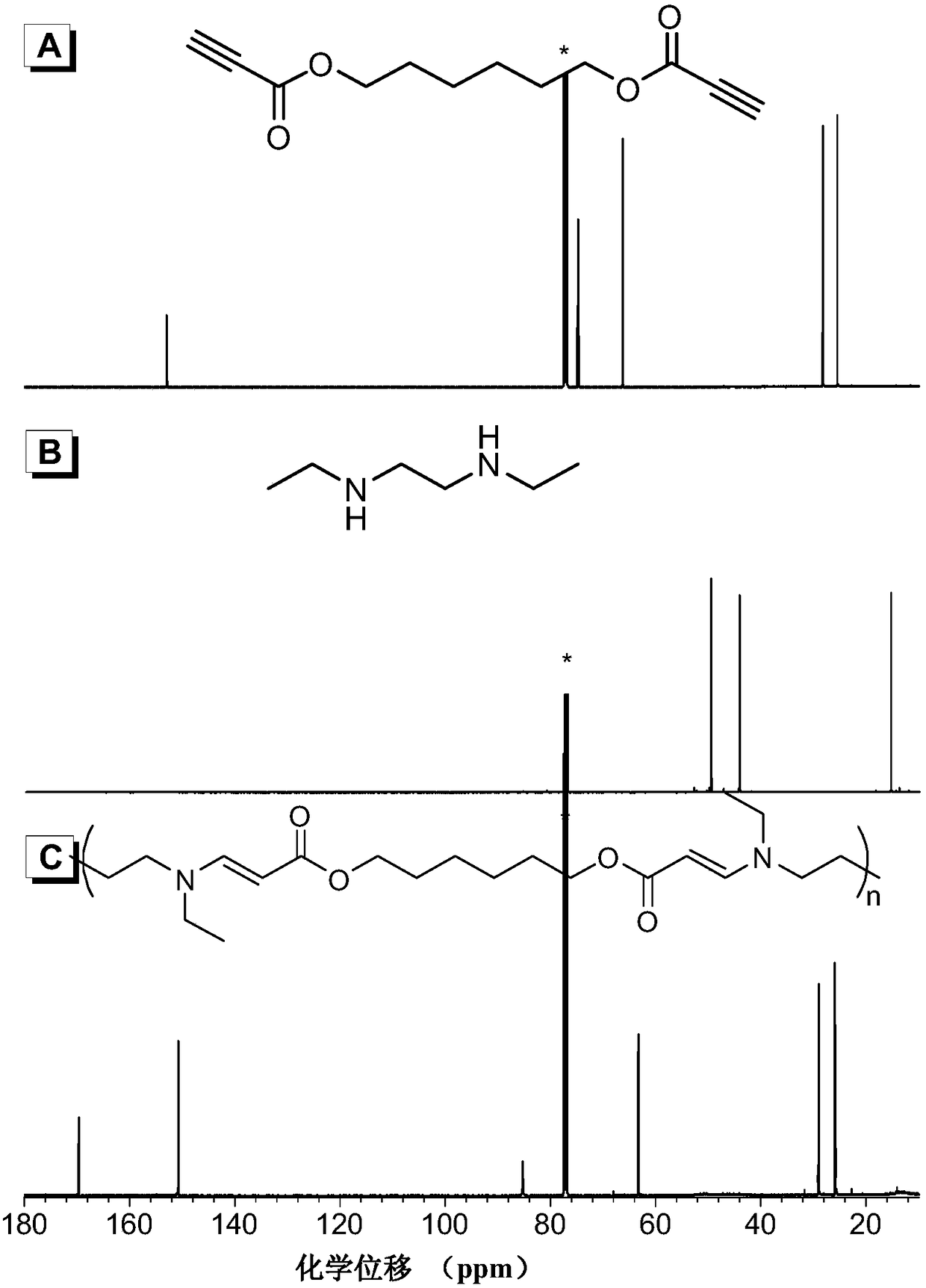

[0044] A kind of polyenamine compound, its structural formula is as shown in P1:

[0045]

[0046] The polyenamine compound is prepared by hydrogen click amination polymerization reaction of acetylenic monomer and secondary amine, and the reaction equation is as formula (1):

[0047]

[0048] Wherein, the synthesis method of monomer M1 can be synthesized according to the synthesis method of the applicant in the published literature (Polym.Chem., 2012, 3, 1075-1083.); M2 is N N'-diethylethylenediamine, It can be purchased from the market, in this example from Adamas Company.

[0049] The preparation steps of described polyenamine compounds are as follows:

[0050] Add 111.1mg (0.5mmol) of monomer M1 into a 10ml polymerization tube, vacuum and change nitrogen for 3 times, inject 250μL of dichloromethane with a syringe, after the monomer is completely dissolved, raise the temperature to 25°C, and finally use a micro injection 58.1mg (0.5mmol) of monomer M2 was added to the ...

Embodiment 2

[0053] A kind of polyenamine compound, its structural formula is as shown in P2:

[0054]

[0055] The polyenamine compound is prepared by hydrogen click amination polymerization reaction of acetylenic monomer and secondary amine, and the reaction equation is as formula (2):

[0056]

[0057] Wherein, the synthesis method of the monomer M1 is the same as that in Example 1; M3 is N,N'-diisobutyl-1,6-hexanediamine, which can be purchased from the market, and in this example is purchased from Alfa Company.

[0058] The preparation steps of described polyenamine compounds are as follows:

[0059] Add 111.1mg (0.5mmol) of monomer M1 into a 10ml polymerization tube, vacuum and change nitrogen for 3 times, inject 250μL of dichloromethane with a syringe, after the monomer is completely dissolved, raise the temperature to 30°C, and finally use a micro injection 114.1 mg (0.5 mmol) of monomer M3 was added to the reactor and reacted for 2 hours. After the reaction was completed, ...

Embodiment 3

[0062] A kind of polyenamine compound, its structural formula is as shown in P3:

[0063]

[0064] The polyenamine compound is prepared by hydrogen click amination polymerization reaction of acetylenic monomer and primary amine, and the reaction equation is as formula (3):

[0065]

[0066] Wherein, the synthesis method of monomer M1 is the same as that of Example 1; M4 is 1,6-hexanediamine, which can be purchased from the market, and in this example, it was purchased from TCI Company.

[0067] The preparation steps of described polyenamine compounds are as follows:

[0068] Add 58.1mg (0.5mmol) of monomer M4 into a 10ml polymerization tube, vacuumize and change nitrogen for 3 times, inject 250μL of dichloromethane with a syringe, after the monomer is completely dissolved, heat up to 25°C, and finally add 111.1mg ( 0.5mmol) monomer M1, reacted for 3 hours. After the reaction was completed, 4ml of tetrahydrofuran was added for dissolution, and the obtained polymer solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com